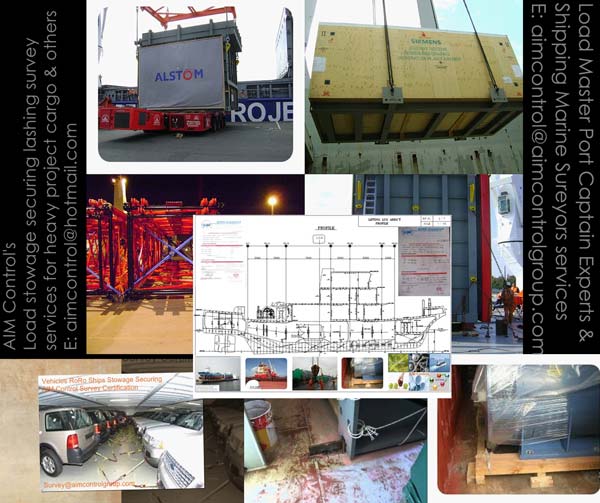

Load stowage securing lashing survey

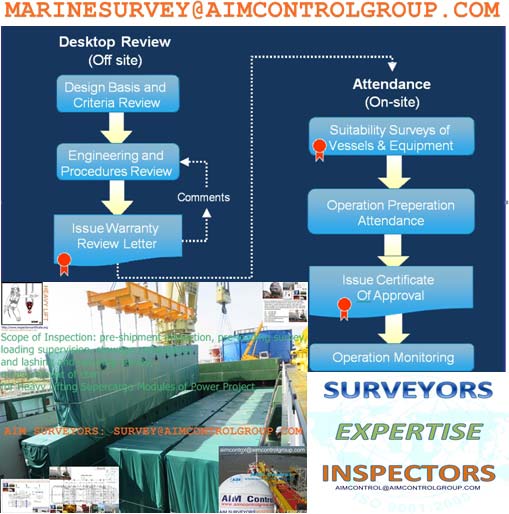

Load stowage securing lashing survey and marine warranty approval

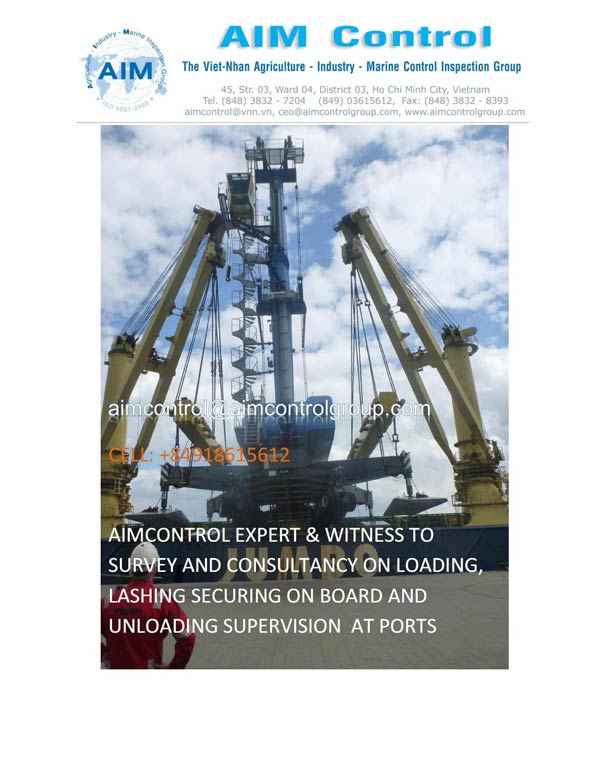

AIM Control is experts in providing load stowage securing lashing survey services that is survey, inspection, supervision, witness, audit, consultancy and certification to control and prevent damage & loss based in Vietnam, China, India, Korea, Asia, Europe, Middle East and Anywhere of Countries. Our Local Email.aimcontrol@aimcontrolgroup.com

Stowage

Stowage is planning of Master, C/O, Cargo Superintendent, Loading Master, Port Captain and Consultant Experts for loading of various cargo on board of vessels and ship to not only prevent damage &/or loss to the goods in shipping and but also more importantly, to minimize the time the vessel spending at the port terminal. AIM experts required to secure survey and consultancy to the cargo unit in a seaworthy condition will be calculated.

Securing

Load securing also known as cargo securing, cargo lashing is the securing of cargo, for transportation as transport by land, transport at sea, transport on air lashing:

Cargo Lashing: Lashing is the securing of various cargo for seaworthiness transportation with the goal of minimizing shifting for cargo lashing include ropes, cables, wires, chains, strapping, and nets and lashing others material.

Loading securing survey, loading lashing survey as well supervision and consultancy carried out by AIM Control securing surveyors, lashing supervisor and consultant, experts as loading master and port captain aiming to prevention of accidents involving shipping can be attributable to inadequate cargo securing.

All of risks threats arisen to cargo that is improperly secured can cause severe damage accidents and lead to the loss of cargo, the loss of lives, cause environmental hazards or furthermore others due to not only the subjective and undiligent of securing lashing concerned parties but also majeure by earthquakes, strikes, enemy sabotage perils and tsunamis.

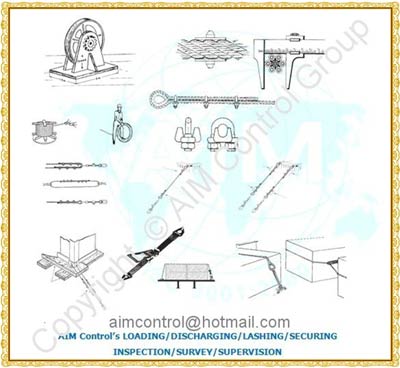

Methods of securing lashing

Blocking & Bracing

Fasteners

Dunnage

Strapping

Lashing

Dunnage bags

Tie downs

others

AIM Control Load stowage securing lashing survey services expert’s securing

-

Know the forces that will be exerted on cargo style

-

Establish if climate conditions will change during your product's journey

-

Plan cargo stowage

-

Inspect the cargo before loading (pre-loading survey)

-

Upon loading ensure that the point of gravity of the cargo is at or near the longitudinal center line of the transport unit. (It is important that adequate load-spreading measures are taken, if so required, to prevent exceeding the maximum permissible loads on a ship’s tank top or hatch covers.)

-

Prevent sliding & tipping of the cargo by proper blocking & bracing the cargo using polyester strapping

-

Use friction increasing anti-slip mats to prevent cargo movement (An important factor in preventing movement of cargo is the frictional force between individual pieces of cargo and the ship’s structure. It can increase frictional forces by using rubber anti-slip mats ot material with a certified coefficient of friction of minimum 0.6µ)

-

Prevent 'fall out at anyway' on arrival at destination

-

Do not assume that heavy cargos don't move! (All cargos, regardless of weight, move when not adequately secured and are subjected to a force greater than the friction forces. Ex: A 10 ton cargo will move just as easily as a 1 ton cargo)

-

Make sure that cargo securers are trained in line with the latest IMO/ILO/UN ECE guidelines (All personnel involved should be trained in the safe packing, stowage and securing of cargos in shipping)

-

Witnessing & Inspect the cargo during loading (Attend the loading of the cargo unit and verify that the loading is performed (according to the lifting plan, using the correct gear, hooks, wires etc, checking for any existing damages, Ensuring suitable lifting gear is utilized)

-

Inspect the cargo during securing and lashing: Supervise the lashing and securing of the cargo unit, Give advice on the position where lashing eyes need to be welded and how the lashing materials are to be applied, Issue a lashing certificate (“sail away certificate”) and/or a report of survey with photographs and calculations; and the overall system complies with the requirements of the IMO Cargo Stowage and Securing (IMO CSS Code)

-

Consultancy: Consulting with vessel's representatives, e.g. Master, Chief Officer, Port Captain on proposed stowage and securing, with special reference to vessel's Cargo Securing Manual and deck point-loads.

-

Certification and Report: in time

Lashing survey and Certification

In shipping, the packing and loading of cargo is always strictly with reason of safety for cargo in transportation.

With cargo (as steel and structure), the lashing survey is important aiming

1. securing for cargo on / in containers

2. loading into cargo holds / on deck

3. safety for ship from port to port

4. safety for mobilizer on the large / lighter from Port's yard

The carriers who ALWAYS REQUEST the shipper to order AIM Group's lashing survey and certification to ensure the cargo is lashed in maritime standards and regulation.

50 years ago in carrying out the Lashing survey and Certification services, we acknowledged and apprised the risks for the cargo to survey and advise the shipper in rules and action as well handling.

The experience and expertise of the maritime and shipping surveyors at AIM Group

- 50 years ago

- According to international standards

- In Associations members

- In quality and Professional

- Standards of all carriers

This trebuchet shows 5 types of lashing: Sheer, Round, Square, Tripod, and Diagonal.

What is safety lashing?

Cargo lashing safety is an essential aspect of transporting goods from one location to another. It involves securing cargo to prevent it from shifting, sliding or falling during transport, which can result in damage, broken and loss.

What is load lashing?

Load lashing or load restraint is a vital component for the safe transport of goods whether this is carried out by road, rail or sea. External forces applied to the load caused by the effects of breaking, accelerating or cornering have a dramatic effect on how the load is to be restrained.

What is frictional lashing?

The frictional load securing

Force-fit securing of the load (tie-down lashing) is performed by lashing straps stretched over the load. The force of the straps is called pre-tensioning force. The goods are pressed onto the loading surface by this force.

How do you calculate lashing?

For those who enjoy mathematics, the relevant lashing forces can be calculated by first measuring the lashing angle α (47.5°) and then the sine and cosine of this angle to determine the vertical and horizontal components and using these in conjunction with the permissible lashing force of the chain. DNV issued the software for calculation on frictional forces and lashed equipment as standards in Maritime.

What is lashing capacity?

Lashing capacity = Maximum allowable tension in the strap. Breaking force = Maximum force the web lashing withstands when tested complete with ratchet and end fittings. The breaking force of the lashing assembly will be twice the lashing capacity

What is direct lashing?

Lashing Straps for Flat Racks | Tie Down Lashing vs Direct ...

Using a direct lashing, the cargo is secured by making a direct connection in the direction of movement between the cargo and the containers or structure of the ship. When a force is exerted on the cargo, this is transferred directly to the lashing material. This allows you to make use of the maximum strength of the lashing material

What is ratchet lashing?

Ratchet Lashing is a Reusable, Cost effective tie-down using polyester webbing & Ratchet Buckle and has replaced ropes, chains and wires used for transportation. The Ratchet Buckle provides the tensioning force. The tension is uniform and locking mechanism ensures that the tension is retained till it is unlocked

What is spring lashing?

Spring lashings are used to prevent cargo from sliding and tipping forward or rearward. The angle between the lashing and the platform bed should be maximum 45°.

What are the two types of lashing materials?

Tension straps, lashing chains and co. – reliable cargo securing on lorries, cars and transporters. Various types of lashing equipment can be used to secure transport goods to and on vehicles and loading areas. Basically, we have two different types of lashing equipment: lashing straps and lashing chains

Kindly refer on our followed services as samples:

See more the AIM Control's load stowage securing lashing survey and discharging for various cargo

See more Sea-fastening survey and approval

AIM Group's locals of marine warranty surveyors and lashing safety certificate services:

Vietnam Albania Algeria American Angola Antigua Argentina Australia Bahrain Bangladesh Belarus Belgium Belize Bermuda Bolivia Brazil Brunei Bulgaria Cambodia Cameroon Canada Chile China Colombia Costa Rica Croatia Cuba Cyprus Czech Denmark Djibouti Dominican Ecuador Egypt El Salvador Estonia Finland France French Guiana French Gabon Gambia Georgia Germany Ghana Gibraltar Greece Guatemala Guyana Haiti Honduras Hong Kong Hungary Iceland India Indonesia Iran Ireland Israel Italy Ivory Coast Jamaica Japan Jordan Kazakhstan Kenya Korea Kuwait Latvia Lebanon Libya Lithuania Luxembourg Macao Madagascar Madeira Malaysia Maldives Malta Mauritius Mexico Micronesia Moldova Monaco Morocco Myanmar Namibia Netherlands New Zealand Nigeria Norway Oman Pakistan Panama Paraguay Peru Philippines Poland Portugal Puerto Rico Qatar Panama Romania Russia Saudi Arabia Scotland Senegal Singapore Slovenia South Africa Korea Spain Sri Lanka Sweden Switzerland Syria Taiwan Thailand Trinidad Tunisia Turkey Turkmenistan Ukraine United Arab Emirates United Kingdom Uruguay US Venezuela Yemen Zambia Zimbabwe.