Bunker Investigation n Bunker Detective

Bunker Investigation n Bunker Detective

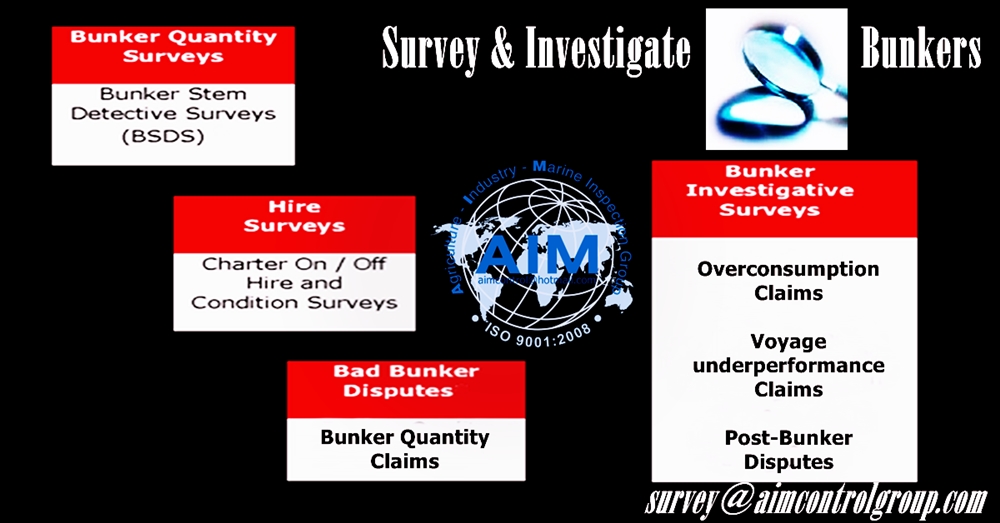

AIM control offers the bunker investigation n bunker detective is to avoid turning a disagreement into a dispute because of fuel losses at the time of bunker shipboard and delivery losses due to pilferage.

Reasons for inviting AIM Control’s bunker investigator by a charterer are different of quantity of fuels (bunker).

Reasons for inviting AIM Control’s bunker surveyor by a Ship Owner are identify of quantity of fuels remained on board (R.O.B),

The end purpose can be only one – to prevent losses because fuel oil expenses are of their budget.

-

Hidden Tanks

-

Fuel Frothing

-

Fuel Log Integrity

-

Magic Pipes

-

Tank Transfers while Bunkering

-

Tampered Measuring Devices

-

Off Hire of ship

-

Bunkering (pumping)

-

Rechecking of bunker quantity (after bunkering, after a voyage)

-

Calculating of consumption of Main Engine and Generators

07 Factors for the Loss of bunker

-

The vessel's crew & staff (on un trust & non-experience)

-

Deficiency experience of the surveyor

-

Deficiency of the vessel on list / trim corrections onboard

-

No full checking of all 6 drafts accurately

-

Malpractices by either party whether the ship or the barge

-

Bunker tank(s) capacity is different from vessel calibration table (after drying dock, tanks repaired)

-

No checking for Net Volume of tanks.

Risks & Loss reducing in Bunker Investigation Detection survey Inspection services

-

Checking of all valves to bunker tanks of the barge and ship to shut before gauging

-

Inter-tank transfers (gravitating of fuel)

-

Checking flow meter tampering and quantity measurements

-

Checking pipe-work tampering, bypass connections etc.

-

Checking tank calibration tables

-

Checking sounding tapes, temperature equipment

-

Inflated volume of tank during gauging

-

Sealing of QCV (quick closing valves) in engine room to storage tanks during bunkering operations

-

Checking of fuel density and weight relationship

-

Checking of fuel temperature and volume relationship

-

Checking of Zero Dip Volume (un-pumpable fuel in empty tanks)

-

Under-Declaring actual ROB and Supplying of Fuel

-

Bunker Dispute Resolution Check List

-

Exact date/time/location and quantity in dispute recorded?

-

C/E advised not to allow hose disconnection?

-

Commercial operator management office contacted immediately for advice?

-

C/E advised not to sign BDN unless advised by the Principals?

-

Agent notified and pilot boarding postponed if applicable?

-

All written evidence is immediately preserved, even scratch notes?

-

Photographs (where permitted) taken as evidence?

-

Bunker delivery hose checked blown-through and clear?

-

QCV (quick closing valves) in engine room to storage tanks (if sealed prior bunkering) still intact?

-

Drafts visually checked again; trim corrected and documented?

-

List ascertained again and verified by clinometers; list corrections applied and documented?

-

Bunker tank modifications (if any) ascertain and revised calibration table for the same sighted?

-

Calibration tables checked for tampering, corrections, insertions, loose pages?

-

Tank calibration tables checked for Class endorsement?

-

Number of tanks / locations verified from Tank Arrangement Plan?

-

Tank capacities verified from Tank Capacity Tables (Machinery Part)?

-

Sounding tape / bob checked for condition, tampering, alteration if not using own equipment?

-

Temperature thermometers checked for tampering if not using own equipment?

-

All valves to bunker tanks checked shut on both the barge and ship before re-gauging?

-

Reference heights / gauging heights verified from calibration tables and same checked against actual measurements during gauging?

-

All tanks visually checked for Cappuccino Bunkers?

-

At least three consecutive gauges taken for each tank and average value used?

-

Inside of sounding pipes checked for dissimilar metals?

-

Sounding pipe flanges/coupling/bolts checked for tampering?

-

Level of oil on the tape accurately ascertained?

-

Density used by barge and vessel the same?

-

Drafts / list re-checked if loading/discharging/ ballasting operations are been carried out at rates to cause appreciable change in trim / list?

-

Entire before and after delivery calculations re-checked for correct interpolation and jointly verified by the C/E and the surveyor?

-

All non-nominated tanks re-checked for any increase / decrease of sounding /ullage?

-

All ballast tanks, cofferdams, void spaces checked for any contamination/leakages?

-

If the discrepancy still remains; supplier's Stock Movement Log Book scrutinized / copies obtained to ensure that the original supplied quantity tallies with the quantity at the time of opening gauge?

-

Barge Vessel Experience Factor (VEF) records obtained?

-

C/E advised to issue letter of protest for each incident and have it acknowledged by the barge?

-

The surveyor given his own detailed statement of facts leading to the short delivery?

-

Photocopies of all relevant pages of the calibration tables obtained?

AIM Control offer the bunker investigation n bunker detective services to prevent the loss of bunker fuel under the qualified bunker detective is impartial, independent quantity measurement and inspection services for marine fuels with a detailed bunker survey report, assuring the fuel delivery and report any bunker shortage.