Ship Cargo Hatch Covers Inspection

Ship Cargo Hatch Covers Inspection

Before loading, AIM Control (AIM Group®) Ship cargo hatch covers inspection and cargo holds survey carried out to ensure the vessel and ship are suitable for loading of cargo. AIM Control (AIM Group®) surveyors also are available to conduct the suitability of containers and other transport means before loading of goods.

Ship’s cargo hatch covers inspection job is the activity of AIM Control (AIM Group®) marine surveyors to identify ship's holds are in cleanliness, drying, free-smell and cargo hatch covers are in watertight condition seaworthiness before loading cargo, in special is loading of grain cargo, Email to order.

The annual cargo damage and loss analysis and statistic by AIM Control (AIM Group®) caused to the leaking of hatch covers as a arising of major cargo claims. Water ingress is often the result of poor maintenance of hatch covers and coamings, or the failure to secure hatch-covers effectively. One of AIM Control (AIM Group®) scope of Marine Surveys for loss prevention is the testing of hatch covers for watertight integrity.

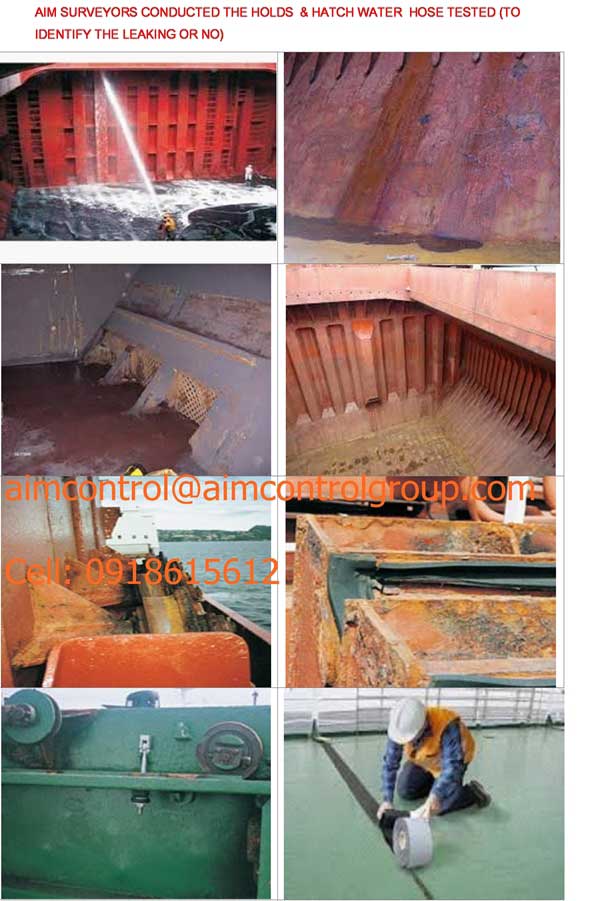

Hose Tests (to identify hatch leaked by water or no)

The ability of the most commonly used hatch covers to prevent water ingress depends upon the existence of a watertight seal between sections of rubber packing and steel compression bars.

A hose test involves playing a jet of water along the cross joints and perimeter seals of the hatch covers at a certain minimum pressure and distance from the structure.

If no water is seen to enter the hold, what the test is demonstrating is the existence of "contact" between the steel compression bars and the rubber packing.

The lack of leakage into the hold is not of itself determinative of a successful test. Checks should also be made that leakage is not passing into the drain channels and being fed through the drain valves onto the deck.

-

Hose testing will discover hatch cover joints that leak. However, the method has its limitations:

-

Cargo holds must be free of cargo (Test cannot be safely carried out when vessel is laden for fear of wet damage to the cargo)

-

Test cannot be carried out if weather conditions/air temperatures are at or below 0oC.

-

The test cannot pinpoint leakages accurately

-

Water pressure variance and the distance of the jet from the structure can affect results

-

Many port authorities will not permit it because excess water on deck can lead to pollution (Excessive water draining from decks when vessel may be alongside wharf, pier or jetty)

-

A minimum of two ship's crew is required

-

Two surveyors are required to undertake the test

-

Ensuring adequate water pressure

The basic procedure comprises placing the transmitter in the cargo hold, switching it on, properly closing and securing the hatchcovers or access equipment to seaworthy requirements.

When the ship is at sea, the ship itself and its hatch and coaming structures are not completely rigid. They flex and "work" to cope with the forces to which they are subjected by the ship's motion and the forces of wind and waves. If cargo damage is to be avoided, the contact between the compression bars and the rubber packing has to be maintained during the periods when the covers and coamings are flexing. The extent to which that contact is maintained depends upon the degree of "compression" that is being achieved by the steel to rubber contact. The higher the degree of compression, the greater will be the watertight integrity in dynamic conditions. A hose test can only demonstrate "contact" not "compression". It is this shortcoming that it makes it a considerably less reliable indicator of overall watertightness than the ultrasonic test.

Ultrasonic Tests

The use of ultrasonic equipment is a modern, viable means of testing for watertight integrity of hatch covers, access hatches, doors, ventilators, etc. It is preferable to use Class approved equipment operated by qualified personnel and to follow approved test procedures.

The test involves placing an electronic signal generator within the cargo hold (laden or not) and using the receiving sensor to first take a reading at the access or booby hatch with the main hatch cover closed. This provides the OHV (open hatch value). The sensor is then passed around the outside of all compression joints noting the reading on the receiving equipment. It is preferable to listen to the signal using headphones to determine the maximum reading at any single point. The readings obtained are then compared with the OHV. The closer they are to the OHV, the greater the degree of leakage. The comparison between actual readings and OHV indicates the degree of compression that exists within the seal, the greater the compression, the lower the reading as a percentage of the OHV. For this reason the ultrasonic test is a much more reliable indicator of watertight integrity in dynamic conditions.

For the purpose of evaluation of results, the following guidelines are usually adopted:

-

Readings of 50% of the OHV or more indicate significant loss of compression and an immediate lack of watertight integrity.

-

Readings of more than 10% indicate potential leakage.

-

Readings of less than 10% indicate watertightness under normal conditions.

A further advantage of ultrasonic testing is that none of the limitations of hose testing apply to this method. The ability to conduct the test with the holds laden is a particular benefit.

Ultrasonic testing will enable the location of leaks to be pinpointed quickly and accurately. After the test, it is imperative to conduct a visual inspection to determine the reason for leakage and thereby determine the appropriate remedial action.

Conclusion

Regardless of method, AIM Control (AIM Group®) Services recommends members to test their vessels’ hatch covers regularly, to watch out for indications of deterioration, and to initiate maintenance early on ensuring cargo is carried under safe conditions. It is, simply put, good loss prevention.

We are providing the Condition of Ship holds inspection and watertight of hatch-covers inspection / as well as container's cleanliness / watertight inspections for client to control the safety of ships and containers before loading cargo.

Place of ship’s holds inspections and Hatchers watertight testing and others: on board of vessel, in ports, anchorage, and harbors, in shipyard, place of loading and other places on global and in Vietnam, Asia, Europe, Africa, America, others.

Times of ship’s holds inspections and Hatchers watertight testing: pre time of loading, before loafing of goods, during dry-docking for new building or repair, at the time of pre-purchase condition survey, seaworthiness survey, and others.

Times of container’s condition inspections: pre time stuffing (before loading), on-hire or off-hire containers, others.

Ship’s holds inspections and Hatchers watertight testing Report/ certificate: AIM Control's ship’s holds and Hatchers inspection reports will be immediately sent you (with photos).

Ship’s holds inspections and Hatchers watertight testing Certificate: AIM Control (AIM Group®) ensures to issue the suitability of ship holds and cargo hatches certificate ASAP to client.

Why does the ship's holds inspect before loading? Most commodities shipped must be protected from contamination from various sources. Some dry bulk cargoes are sensitive to humidity, some are exposed to attack from vermin and insects and some may risk decomposition if contained in wrong environment. Most liquid cargoes can potentially be contaminated by external sources and other liquids such as a different cargo in an adjacent cargo tank, incorrect temperatures and even hazardous chemical reactions with other liquids or substances.

As our core business concerns inspection of products and cargo inspection, goods survey that will be used for human food or animal feed we emphasize the importance of a throughout ship holds and container cleanliness inspection before loading of products into ship’s holds and tanks, as well as containers shore tanks, railway carriages, trucks, containers etc. Also to avoid contamination the condition of any cargo discharged is thoroughly inspected before transferring to another location.

This vessel's holds inspection services applies to inspection/ assessment/ verify of condition of ships holds and tanks are suitable for loading kind of cargo/ goods/ products to ensure that the areas/units that are to carry the agricultural goods, cargo, products. We also offer pre-shipment inspection services for containers, railway cars and barges and lighters and trucks. The inspection/ verify / assessment services is also applicable to land installations like warehouses, silos and tanks.

-

Ship's holds free from dirt, odors, cargo residues, foreign matter or infestations, cargo residues or pest infestation inspections.

-

Ship's Cargo Hatch Covers watertight inspection and safe for consignment, the cargo transported inspection.

-

The inspection of ship's holds and cargo hatch covers to assurance that your consignment will be transported in a clean and safe manner.

-

The inspection of ship's holds and cargo hatch covers to minimal risk of loss or damage to your consignment during shipping and storage.

We have an independent inspectors, marine surveyors and consultant experts providing the ship's holds and Cargo Hatch Covers inspections and certificate the evidence of ship's holds and hatchers covers are safe to load of cargo based in Vietnam, China, India, Korea, Singapore & Asia, Italy, Germany, U.K Russia & Europe, the Middle East, Brazil, Chile, Argentina & etc., Anywhere of Countries to protect your orders in good condition. Email: aimcontrol@aimcontrolgroup.com,aimcontrol@hotmail.com, cell: +84903615612.

Also see AIM Control (AIM Group®) the holds condition surveys / inspection services of AIM Control (AIM Group®) Inspection Group