Container Inspection

Container Inspection

AIM Control works in this field offering container inspection to a recognized shipping company, carrying out, seal inspection, transshipment inspection, stuffing/loading inspection, quantity & quality goods inspection, condition cargo loading inspection, pre-shipment inspection, and cargo damage inspection. Email

AIM Control's team of shipping container surveyors is trained in the management of Goods, Dangerous Cargoes, these technical container inspections are carried out for trained engineers certificate our clients a careful and safety inspection and a excellent report.

Also we conduct survey to establish the structural condition of containers, to provide a description of the damages which affect structural integrity according to IICL5 Code together with an estimate of the repairs cost.

Container Inspection Procedure of AIM Control Inspection Group

-

Procedures must be in place to verify the physical integrity of the container structure prior to stuffing, to include the reliability of the locking mechanisms of the doors.

-

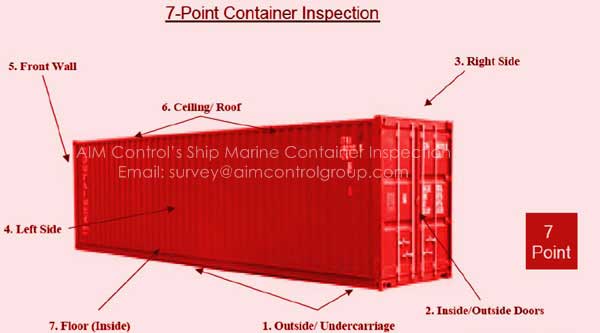

Container 7-point inspection Process is recommended for all containers.

Inspection on main structure of container standards

-

Outside/ Undercarriage (before entering facility)

-

Inside/ Outside doors

-

Right side

-

Left Side

-

Front Wall

-

Ceiling/Roof

-

Floor (Inside)

Container inspection checklist

Undercarriage

-

Inspect prior to entering facility

-

Support beams should be visible

Outside/Inside Doors

-

Secure and reliable locking mechanisms

-

Look for different color bonding material

-

Loose Bolts

-

Plates and repairs

Right/Left Sides

-

Unusual repairs to structural beams.

-

Repairs to the walls on the inside of the container must be visible on the outside.

-

Use tool to tap side walls.

Front wall

-

Blocks and vents are visible.

-

Use tool to tap front wall.

-

Range finder, measuring tape and/or string can be utilized to determine the length of container.

Ceiling/ Roof

-

Ceiling is a certain height from floor. Blocks & vents are visible.

-

Uncomfortable feeling inside container.

-

Repairs to the ceiling on the inside of the container should be visible on the outside.

-

Use tool to tap ceiling.

Floor

-

Floor should be a certain height from the ceiling

-

Floor should be flat. !

-

Different floor heights

-

Unusual repairs

Point Tractor & Trailer Inspection Process

-

Procedures should be in place to verify the physical integrity of the trailer structure prior to stuffing, to include the reliability of the locking mechanisms of the doors.

-

Border crossing tractors & trailers should be inspected upon arrival at the domestic facility.

-

Point Tractor & Trailer Inspection Process is recommended for all trucks and trailers arriving from foreign.

-

Bumper

-

Engine

-

Tires (truck & trailer)

-

Floor

-

Fuel Tanks

-

Cab/ Storage Compartments

-

Air Tanks

-

Drive Shafts

-

Fifth Wheel

-

Outside/ Undercarriage

-

Floor

-

Inside/ Outside Doors

-

Side Walls

-

Ceiling Roof

-

Front Wall

-

Refrigerated Unit

-

Exhaust

Please kindly review Inspection of goods stuffing/loading into container before exporting or Marine survey of AIM Control Inspection Group.

Also see our Container Inspection services in relation

Container loading Supervision services,

On-hire & off-hire container survey

Cargo Inspection services and loading supervision into Containers

Cargo Pre-shipment inspection services

Loading Container Inspection Report

See more 19 types of containers in shipping