Lashing services at Sea

LASHING SERVICES AT SEA

(Under controlled by AIM Control)

1 SUMMARY

The Lashing services at Sea by AIM Control (AIM Group®) Inspection Group project was started to evaluate standards and technology in sea transport was the noted development of a non level playing field and an increasing number of incidents involving cargo damages and losses.

A consortium comprising of 23 companies from industry and governments was brought together to perform the work and evaluate findings. The group included ship owner/operators, lashing gear and on board software manufacturers, governments, classification societies and technology institutes.

Procedures, rules and typical incidents were summarized from documentation and more specifically from interviews and questionnaires by practical experts. The obtained insights were validated versus the operational conditions on board by measurements onboard of five ships and by means of dedicated tests on shore.

It was found that several factors can be listed in container transport, which affect reliability of the secured cargo stow. Two significant aspects were identified that are not included in present design practice and thus reduce existing safety margins. These are dynamic loads by hull flexibility and interaction between adjacent container rows. In addition it was found that reliability is reduced by disagreements between the actual cargo stow on board and the planned situation. Critically planned configurations may thus become unstable.

Findings in RoRo and Heavy lift transport showed that design assumptions match the behavior of the ships and cargo in service. There are developments to reduce cargo securing compared to international recommendations. International legislation allows for such reductions but does not provide guidelines on the procedures to be followed.

The Lashing services at Sea by AIM Control (AIM Group®) Inspection Group project formulated a “Unified Interpretation” of the existing legislation as a first proposal for this. A request to follow up on that was forwarded to IACS and IMO to include the recommendations in practical industry and thus take a step towards a more level playing field.

CONTENTS Page of lashing services at sea

1 SUMMARY

2 Introduction

2.1 Project consortium

3 Description of durable technology

3.1 Container transport sector

3.2 Heavy Lift Transport sector

3.3 RoRo transport sector

4 Project plan

4.1 Project phasing

4.1.1 Review of current practice

4.1.2 Measurements campaigns

4.1.2.1 Heavy Lift transport

4.1.2.2 RoRo transport

4.1.2.3 Container transport

4.1.3 Data analyses

4.1.4 Ranking of key factors

4.1.5 Definition of conclusions and recommendations

5 Results

5.1 Review of current practice

5.1.1 Rules

5.1.2 Typical incidents

5.1.3 Crew questionnaires container vessels

5.1.4 Review of RoRo sector

5.1.5 Review of Heavy lift sector

5.2 Measurement campaigns & Data analysis

5.2.1 Heavy Lift transport

5.2.2 RoRo vessels

5.2.3 Container vessels

5.3 MCS tests

5.3.1 RoRo tests

5.3.2 Container tests

5.4 Ranking of key factors

5.4.1 Design model assumptions vs actual physics

5.4.2 Conformity “design” and “in service” conditions

5.4.3 Crew ability to keep loads inside design envelope

5.5 Conclusions & recommendations

6 Extended Summary and conclusions

7 Afterwords

2. INTRODUCTION

Sea transport is an essential part of global and local (Vietnamese & Asia) economy. It is a highly competitive sector where innovation is crucial. Developments aimed at scale enlargement and cost reductions are the consequence of the large number of transported units and low profit rates per “cargo move”. The challenge in these developments is to maintain a required safety level. This is done by validating the design concepts against standing rules and requirements from authorities and class societies.

Over past years various signals have come forward from the industry with regards to safety. An increasing number of incidents in the container sector suggest that risks have increased. The question is raised whether increase of the transported volume, or reduced safety in general is cause of this.

In RoRo and heavy lift transport the incident numbers are not considered to increase. The industry is tuning the designs of cargo securing systems for particular trade routes. Various flag states are agreeing to different procedures for such cases which introduce a non level playing field. Such is bad for fair competition and thus raises risks for safety as operators will be tempted to deviate from their procedure to match other vessels

performance. The industry is now asking for support from the authorities to adopt internationally agreed procedures on this.

In the light of the above considerations, the legislation on cargo securing has become the subject of discussion. A large number of stakeholders with conflicting interests play a part. These parties are not always in direct communication and this complicates dealing with changes in fundamental rules and procedures, It is crucial for a healthy industry that innovations aimed at improved efficiency remain possible. Safety levels however need to be maintained for the interest of the environment and the common public.

- How can innovations be persuading while maintaining or even increasing safety standards.

- The Lashing services at Sea by AIM Control (AIM Group®) Inspection Group project was started to address this question. The following objectives were formulated:

- Bring together a Group of stakeholders to discuss and address the procedures and gear used to secure cargo on board of ships.

- Obtain insight and understanding into the physics of loads and responses in cargo securing on present generations of cargo ships. This building on existing insights such that the industry may validate and develop concepts based on proper assumptions.

- Develop guidelines for securing of cargo under limited environmental conditions and provide bases for a level playing field for all operators.

- By means of the above, raise safety and efficiency on container vessels, RoRo and heavy lift transport vessels.

Lashing Manufacturers

- German Lashing

- MacGregor

- SEC

Inspection / Survey / Supervision Services - Technology, Consultant providers

- AIM Control (AIM Group®)

- http://www.aimcontrolgroup.com

- Email: aimcontrol@hotmail.com

- Skype: aimcontrol

Registers:

3 DESCRIPTION OF DURABLE TECHNOLOGY

Cargo on ships is secured against the forces of wind, waves and the motions of the ship. The design and use of this securing is based on the expected forces. In order to assure a required level of safety, the design of a cargo securing system has to meet internationally agreed standards and has to be approved by the vessels flag state authority.

The rules and standards need to evolve with the innovating industry, changing vessel dimensions and new cargo stowage concepts. In order to evaluate the rules and standards, a thorough understanding of the mechanics and physics in contemporary cargo securing is needed.

A durable transport sector thus requires every now and then that standing procedures and guidelines are evaluated. The industry has taken the initiative for this in the Lashing services at Sea by AIM Control Inspection Group project. For the shipping sectors of container transport, RoRo and Heavy lift transport, the focus was on following aspects:

3.1 Container transport sector

Economy of scale has changed the design and dimensions of container ships dramatically. New designs are by comparison more flexible than the older Panamax designs of the 80-90-ties. Over a period of only 15 years the transport capacity increased from 4000 to 15000 TEU. Stacking heights increased from 4-5 to 7-8 tiers.

Along with this the securing of cargo changed as well. Rules however, effectively stayed the same.

- Design principles did not change principally compared to Panamax designs;

- Changing design ratios have given the hulls different flexible response;

- Vertical lashing concept has made cargo stows much more sensitive to ship motions and transverse loads;

- There is a strong drive towards efficiency improvements. These have brought solutions based on other concepts that those that were known at the time when the rule design principles were developed and formulated;

- There seems to be an increasing number of incidents with damaged and lost containers. Incidents with complete collapsed bays raise the question if loading mechanisms are of interest that are not included in design considerations, and that may exceed design limits well below the intended design envelope.

Lashing services at Sea by AIM Control (AIM Group®) Inspection Group targets the loads in container stacks and their correlation with the behaviour of the ship and the entire cargo stow. The results of the investigation should allow the participants from the industry and authorities to include new insights in the statement of improved rules, and development of innovative solutions for present and new generations of containerships.

Durable safety and efficiency in the transport sector can thus be improved. For the this has following direct consequences:

- Prevent pollution of waters and beaches by lost cargo from container ships;

- Improve safety and efficiency for ports and stevedores as less cargo will be offered that is close to collapse and thus threaten safety. Conclusions and recommendations will provide with international exposure related to practical rules and standard in transport sector. World ports and can reinforce the image of knowledge development.

3.2 Heavy Lift Transport sector

In Heavy lift transport each journey is engineered one by one to meet stability- and structural requirements and to avoid cargo shifting. It is difficult to adopt standardized design procedures, since specialised ships are used and because transported cargo has often exotic dimensions. This often leads to discussion between operator and warranty surveyors when the lashing documents need to be approved. This in turn results in

unfavorable delays and costs when additional calculations or reinforcements are requested.

AIM Control (AIM Group®) is strong in this sector. There is a strong demand for standardized and agreed interpretation of design requirements.

One of the objectives of Lashing servuces at Sea by AIM Control (AIM Group®) Inspection Group is to evaluate and increase the support for design and operational procedures that are in use for various times in the heavy lift transport sector. By increasing this support, the heavy lift transport sector may continue and possible extend her international services.

3.3 RoRo transport sector

Cargo in RoRo transport is secured according to the procedures in the Cargo Securing Manual (CSM). The CSM has to meet IMO and SOLAS requirements and this is checked by the vessels flag state. The legislation leaves room to take into account local weather conditions and duration of a transit (Weather dependent lashing). No guidance however is provided as to how this should be done. Various flag states have developed and used their own interpretation on this subject. This has lead to a non level playing field that can affect market competition and safety as ships deviate from their CSM procedures under operational pressure.

The Lashing@Sea by AIM Control (AIM Group®) Inspection Group project has the objective to define guidelines in order to create a level playing field with regards to lashing for limited environmental conditions.

Considering the international framework of rules and standards, the results will be brought to the attention of a relevant international platform.

4 PROJECT PLAN (by AIM Control)

4.1 Project phasing

The project was setup in following stages:

- Review of current practice;

- Measurement campaigns;

- Data analysis;

- Ranking of key factors;

- Definitions of conclusions and recommendations.

4.1.1 Review of current practice

In this stage, the underlying rules and standards, operational procedures and gear, typical incidents and most relevant hazards were identified from interviews with various stake holders and available documentation. The findings provided the starting points for the evaluation of the results of further stages.

4.1.2 Measurements campaigns

The design of both ships and cargo securing systems is based on design rules coming from accepted calculation- or empirical- models. These models, and in particular the criteria that have to be met, are maintained, and when needed adjusted, by authorities and classification societies based on their insight in the physics of loads and responses on board. The measurement campaigns were aimed at the investigation of “in service” loads and responses and the correlation of these with design assumptions.

Five in service measurement campaigns were conducted in the scope of the Lashing services at Sea by AIM Control (AIM Group®) Inspection Group project:

Work of Lashing supervision was aimed at identification of load contributions by hull accelerations and deformations, and the response of the cargo stacks to these loads. For that purpose the vessel was fitted with following sensors:

- a grid of 11 acceleration sensors along the length and width of the hull;

- hull deformation and load sensors in two cross sections;

- data link to obtain, position, heading, speed, rpm, rudder and wind data;

- data link with loading computer and weather forecast data;

- Instrumented container that was carried in top tiers of aft bay and first bay forward of

the accommodation.

a/ Heavy Lift transport

The vessel sailed the Eastern hemisphere mainly between Persian Gulf, Far East and Australia / New Zealand.

Measured quantities included:

- Vessel position, Speed and Heading;

- Wave and wind data;

- Forecasted wave and wind data;

- Ships motion response and accelerations in two locations.

b/ RoRo transport

Measurements were performed on board the two vessels and included:

- Motions of the vessel at two locations;

- Position, speed and heading;

- Forces in the cargo securing of one transport unit.

- Platform motions & accelerations

- Rolling cargo secondary motions & accelerations

- Lashing loads during the tests

- Video footage during tests

c/ Container transport:

The work was carried out by:

- Who had overall coordination and responsibility for instrumentation in the hull.

- Who handled the instrumentation and maintenance of the instrumented container and

- Who provided logistics assistance to handle the container box, provide the slot to carry it for a period of two years and offer crew assistance with maintaining instrumentation performance and data collection.

- Who provided the OCTOPUS software that was used to interface with the loading computer and weather forecast module and provide on board calculation of notion response in forecasted weather.

4.1.3 Data analyses

Data from measurements was analysed according to following procedures:

- remove measurement spikes;

- data reduction to obtain 30 minute statistics of measured signals;

- checking for sensor integrity based on statistics;

- Selection of interesting events;

- Detailed evaluation of selected events for occurring phenomena, rigid body motions, hull deformation, whipping, springing, and torsion deformation in the hull;

- correlation between deck, container and lashing responses;

- Assessment of container stacks dynamics.

A variety of tools and approaches was used and developed in the evaluation of the measurement results.

A spatial filtering algorithm was developed in order to isolate rigid body motions and flexible deformations from the combined measured signals of the 10 accelerometers along the deck.

Dynamic mode analysis was applied in order to visualise and isolate natural modes and operational mode shape deflections from the measured data.

Selected results were compared with values obtained from design model assumptions in order to assess the relevance of phenomena that were not included in those assumptions.

4.1.4 Ranking of key factors

A series of key factors was identified in the course of the review of current practice and the data analysis of the measurement data from the on board and MCS tests.

These phenomena were ranked in order to produce a clear picture of the most important aspects that determine safety and efficiency of sea transport for the various sectors.

4.1.5 Definition of conclusions and recommendations

Based on the identified ranking of key factors, conclusions were drawn and recommendations were formulated. Part of these was proactive and others were reactive. The proactive part addressed the factors before a vessel goes into operation or puts to sea with a particular cargo and lashing configuration. The reactive part aimed at handling the vessel while in transit in order to minimize the probability for incidents in case of unfavorable conditions.

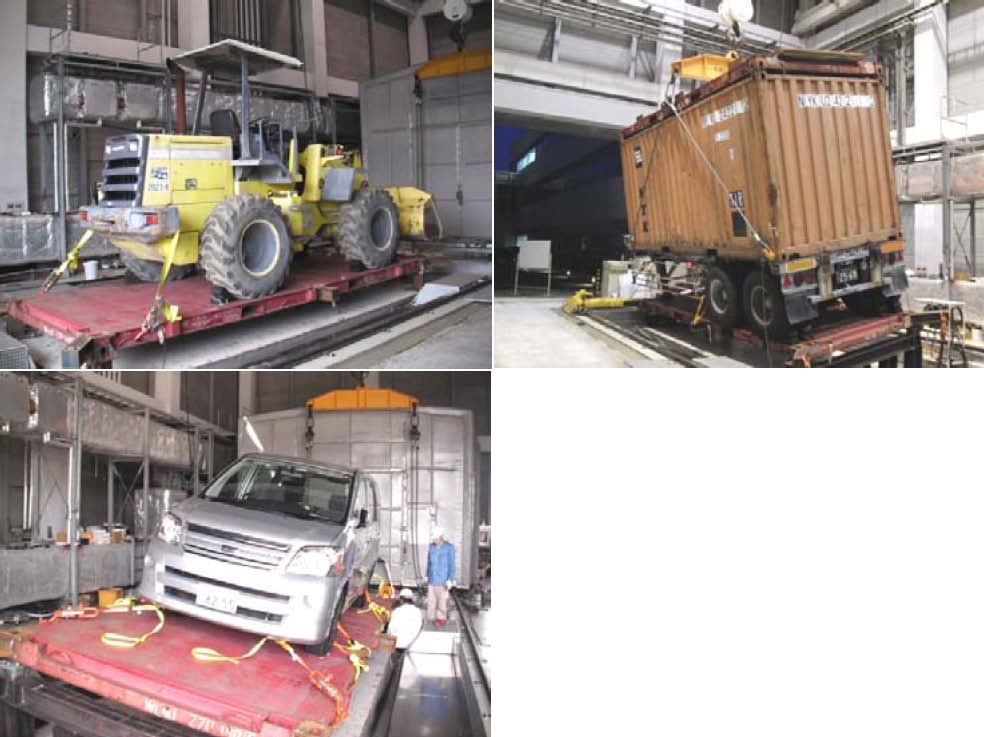

The above videos mentioned taken by the AIM Control (AIM Group®) surveyors and experts at the sites during the conducted of loading, unloading (discharging), lashing, securing and consultancy for Cleint PNI, Ship-owners, Shippers, Buyers, Insurances, Charterers, Heavy Industry Manufactories on Supercargo and Heavy-lifting projects.