Pre-loading Survey

Pre-loading survey

The pre-loading survey is first step of shipment survey procedure on loading in shipping with target to determine the "limits of liability" of the concerned parties regarding to cargo condition.

On shipment

Before loading of shipment into means of transportation of shipping carrier as motor vessel, the condition of cargo must be carried out the survey to identify its nature & apparent actual condition in detail and packages called Cargo pre-loading survey. (if before loading of cargo into containers, it is called pre-shipment inspection)

Purpose of pre-loading survey

Purpose of goods pre-loading surveillance is to certify that cargo’s condition as contaminated (salt water, high moisture, rusted . . .), physical damage (broken, dent & bent . . .) defected & deformed or un-suitable condition prior to loading aiming to protect the carrier’s right under the contract of carriage until this shipment will be discharged at destination port when arising claim of consignee (as buyer, receiver or any parties) to the shipping carrier (instead of seller, supplier or shipper on fraudulent or responsibility).

Sometime, the measurement of cargo’s volume also carried out for calculating of freight costs.

See example Steel products quality inspection / pre-loading inspection and loading survey

On means of transportation

Before loading, the condition of cargo holds & containers (as well cargo gear, seaworthiness), hatch-covers and ship’s ventilation system must be carried out the inspection to certify that its condition is suitable for loading of cargo.

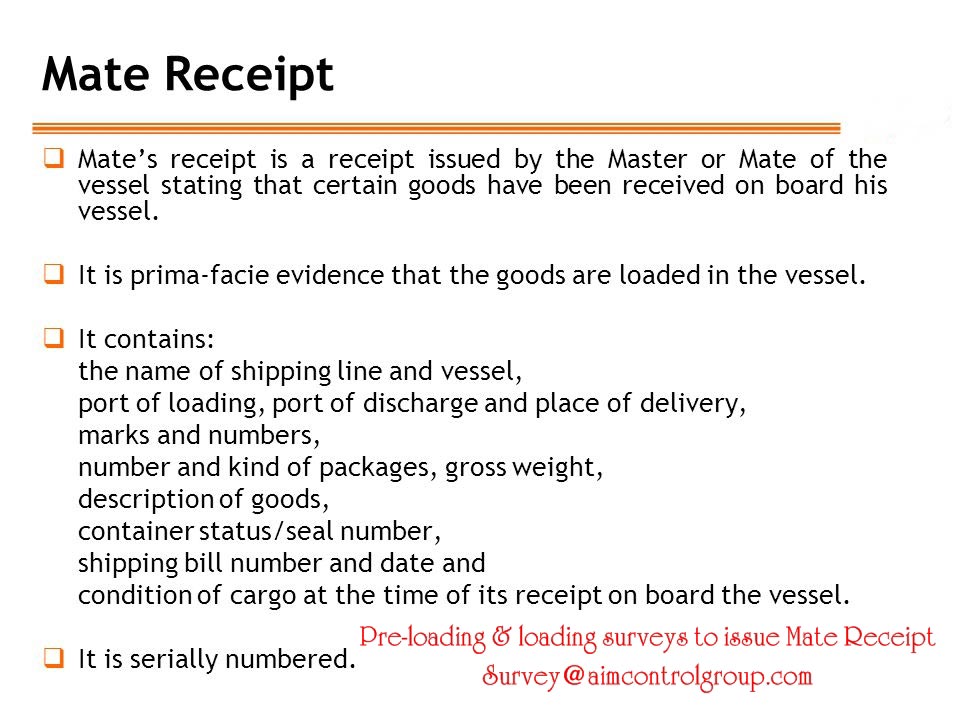

Basing on AIM Control (AIM Group®) pre-loading report of survey, Master of ship will be issue Mate receipt list report to attached with Bill of lading.

if the report of cargo pre-loading inspection is results any differences against the described in the shipping documentation, whether to refuse (reject) the cargo or early notification of these deficiencies to the shippers (agents, stevedores or charterers) together with Carrier

Kind of cargo to be surveyed on pre-loading

All of cargo types must be surveyed by AIM Control (AIM Group®) before loading, especially for goods that are either easily altered on apparent condition or nature damaged for short periods of time, such as a pare iron and steel products are easily oxidized due to environmental influences, fresh seafood is fast spoilage, fresh fruit is quickly rotten (too ripe), agricultural commodities are moldy (its high moisture & humidity).

AIM Control (AIM Group®) surveyor inspects the cargo on the quay, seller’s premises, prior to the container or the ship’s arrival (period loading) and report to the master on its condition and advise the master on the clauses of the mate’s receipts and give advice on loading and stowage.

Survey on nature & apparent actual condition of cargo with report.

Advising Master on cargo holds cleaning, repairing on the failures, supplying dunnage material and lashing tools.

Advising the master on loading, stowage and securing.

Monitoring the loading, stowage and securing.

Advising and reporting on handling damage caused by stevedores.

Carrying out & Advising on the tallying of the cargo and the issue of cargo documentation.

Advising if the cargo can be loaded in rain and a dirt particles dust flying in the air to cling the cargo

Acknowledged the charterparties Clauses relating to damaged cargo, responsibility for loading and stowage, issue of the mate’s receipts and bills of lading . . .