Pressure vessel inspection

Pressure vessel inspection

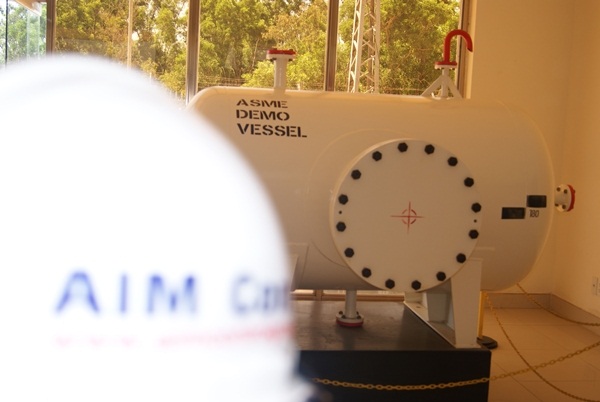

Pressure vessel inspection carried out by AIM Control’s expediters (ITP & mechanical inspectors) period of it fabricated at a heavy industry manufacturer under the inspection testing plan (ITP) to meet with API and ASME Codes.

Pressure Vessels are described compressors, boilers, autoclaves, tanks and its associated pipe work and devices, stored dangerous goods as gas, oil or liquid under high pressure.

Main important points Pressure Vessel inspection of AIM Control

-

All plates need to be identified against mill test certificates at the Vendor.

-

Ensuring that welding procedure and welders are qualified and welding electrodes are approved.

-

Selection of location for spot radiography

-

Reviewing of radiographs

-

Witnessing of hydrostatic test

-

Dimensionally checking and carrying out final internal and external inspection.

-

Checking that all material test certificates and, heat treatment charts are in order.

-

If specified witnessing any crack detection, hardness checks, ultrasonic tests.

-

Checking fit-up and chipping-back of welded seams.

-

Monitoring welding process based WPS

-

Monitoring all NDE activities

-

Ensuring that Vendor is familiar with the requirements regarding data books and ensure that the documentation is submitted without any delay.

-

Checking internal lining of reactors and vessels (if applicable) to specifications.

-

Checking trays of each diameter and type, mock assembled in the shop. (for process towers)

-

Checking for interchangeability of parts, where applicable for process towers

-

Ensuring that any uncommon down comers are fully assembled and offered along with their respective trays. (for process towers)

The ASME Code Section VIII Div. 1 or 2 requirements normally are applied for inspection and test plan in pressure vessel manufacturing shop.

The witness of inspection and test by AIM Control’s ASME authorized inspector team as third party.

AIM Control’s authorized inspectors monitored in fully witnessing of resident or man-days of visit for items to quality control system of the pressure vessel manufacture.

See more:

-

Mechanical Inspectors, Engineers, Vendor Inspection in Vietnam, Global

-

Mechanical engineering

-

Mechanical inspectors

-

Electrical engineering, inspectors

-

Mechanical inspection

-

Quality assurance

-

Material inspection

-

Fit-up inspection

-

W.P.S & P.Q.R review

-

Welder & Welding operator test

-

Welding Procedure Qualification Test

-

Heat Treatment Chart Review

-

N.D.E(RT, UT, MT, PT)

-

Visual Inspection

-

Dimensional Inspection

-

Assembly inspection

-

Pressure Test

-

Functional and Performance Test

-

Mechanical Running Test

-

Surface Preparation and Painting inspection

-

Packing Inspection

-

Release Inspection

-

Loading Inspection

-

Field Installation and Maintenance Inspection

-

Progress Expediting

-

Review of Contract & Job Specification

-

Review & witness of a material testing and mill certificate

-

Prepare of WPQR & WPS and Welder qualification test.

-

Visual inspection of welding & dimension during fabrication and installation

-

Visual inspection of Surface Preparation for painting

-

Perform of pneumatic & hydro’ test

-

Supervisory Activities & Expedition for Shop Fabrication and Site Erection

-

Experience with Code and Rule: ASTM, AWS D1.1, ASME, ANSI, API, JIS, KS, SSPC, EMA.UOP and etc

-

Experience with ASME Section VIII, Division 2 Pressure Vessel Code

-

Etc.