Cargo hold cleanliness inspection / water-tightness / sealing

Cargo hold cleanliness inspection / water-tightness / sealing

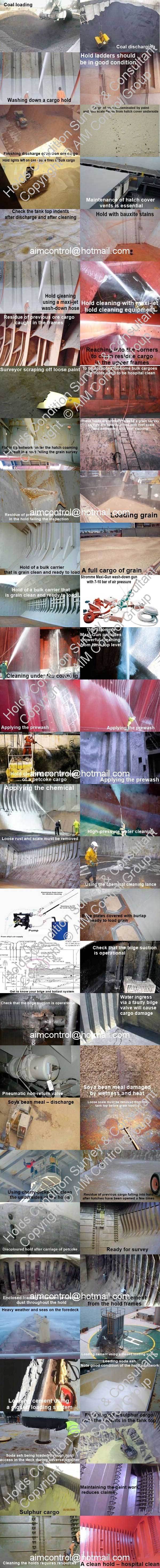

To ship a variety of bulk cargoes into marine vessel, the cargo hold cleanliness inspection carried out for identifying to be in its physical clean condition.

Prior the shipped, the hatch covers of each cargo hold must be tested for checking of water-tightness condition to protecting the loaded cargo in a ship.

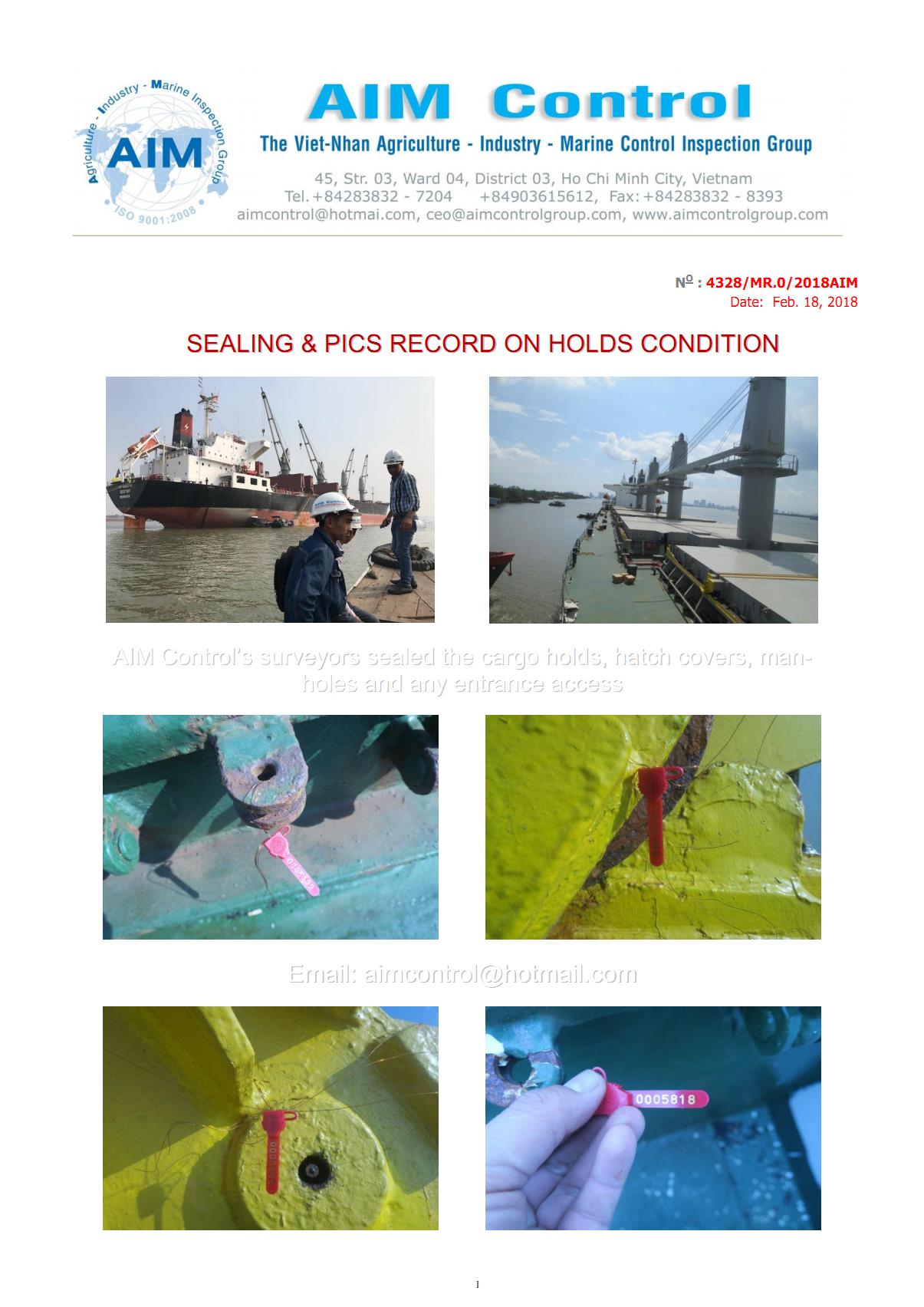

After the loading of cargo to be completed, the cargo holds, hatch covers, man-holes and any entrance access must be sealed to prevent the theft or the action of crime.

AIM Control’s experience 30 years surveyors can inspect on all a cargo hold cleanliness inspection / water-tightness / sealing as well on reporting and consulting to a Master of ship and his crew to resolve the remaining.

As roles of third party inspection, AIM Control offers the cargo hold cleanliness inspection / water-tightness / sealing and consultancy

AIM Control's cargo hold cleanliness inspection & consultant

AIM Control’s inspectors & surveyors carry out the inspection on a maritime ship’s cargo hold condition is to verify it’s suitable for ready receive cargo:

-

Ensure that the hold is free of rust or paint chips that could contaminate or discolor your cargo

-

Providing assurance that the hold is free of previous cargo remnants, including inaccessible areas

-

Looking for evidence of wooden partitions or dunnage that may react with cargo and ignite

-

Examining the ship’s log for evidence of previous cargo containing materials that may put your cargo at risk

-

Paying special attention to previous cargos including seed or grain that may lead to consequences due to quarantine requirements

-

Checking for any signs of moisture or previous water damage in the hold or bilge.

-

Consultancy to Master, C/O and P&I

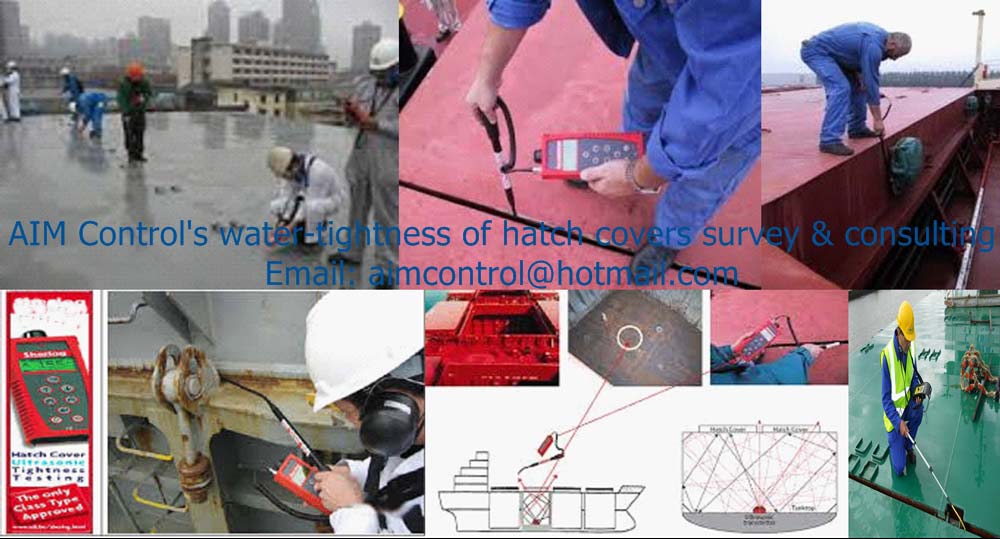

AIM Control's water-tightness of hatch covers survey & consulting

-

A visually surveying hatch covers at departure and arrival for water tightness and proper operation

-

Looking for obvious damage, holes and leak points that may jeopardize the quality of the cargo

-

Conducting Chalk, Hose and Ultrasonic Leak Detection (ULD) tests for objective assessment and verification

-

Complete, independent hatch and hold inspections are commercial carrier inspection services offered by AIM Control, a trusted leader in bulk cargo management.

-

Consulting to Master, C/O and P&I.

Sealing & Reporting

-

A visual checking of kind of ventilation

-

A visual verifying of the cargo holds, hatch covers, man-holes and any entrance access

-

Sealing actions are suitable to be secured but vessel can be ventilated preventing in consequence of moisture/damage to cargo.

-

Taking of photos, number of seals and reporting

Place of Ship cargo hold cleanliness inspection / water-tightness / sealing: at ports, anchorages area, loading ports, unloading/ discharging port, before on-hire, off-hire, others.

Purpose of cargo hold cleanliness inspection / water-tightness / sealing: for buyer, shipper to ships are of seaworthiness and meet to load and transport goods at sea, for claim, for P&I, for on-hire / off-hire, for PPI and ect.