Container loading inspection services

Container loading inspection services

Container loading inspection services are container loading inspection (CLI), container Loading survey (CLS) it is It’s known also container loading supervision.

Container loading inspection services are carried out during the process of international trade and shipping between one country to each other countries, from the place of export to the place of import at the time of delivery.

How to export or import goods safely?

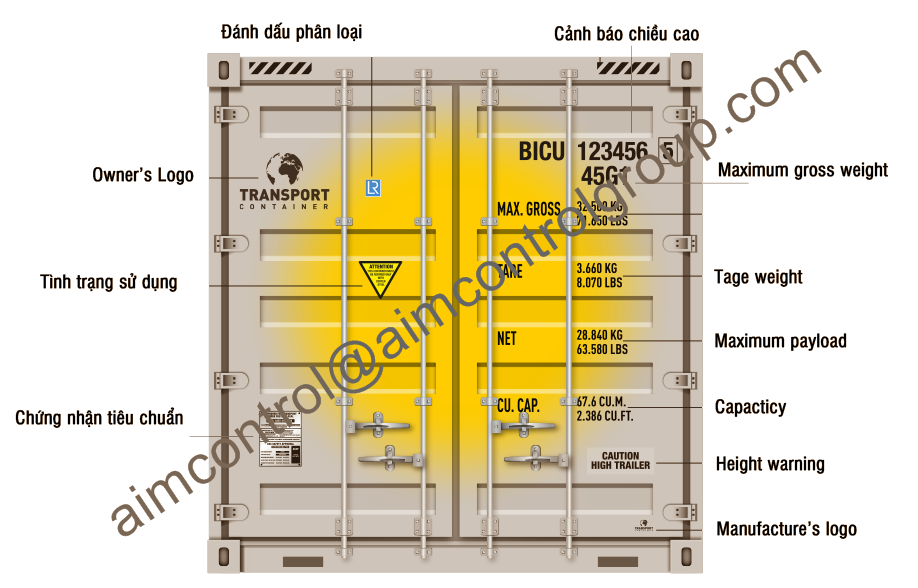

Container loading verification is to check condition of container and in-container shipments after that issuance of certification quantity, quality and safety in shipping

From exporting country to the importing place

-

At the place of export, the goods are inspected during loading into the container, it is called container loading inspection services

-

At the place of importation, cargoes are inspected during unloading from the container, it is called a container discharging survey services.

Besides the basic skills that you should follow to have a successful and reliable import shipment from the exporting country, from choosing suppliers to the accuracy products as required for importing. But the most important of all the necessary procedures is to ask the Inspector.

When importing goods at the countries far away from you, it is not a simple task because these transactions are related to trading strategies, the whole procedure needs to be accurate or authorized to be successful all the attributes from the initial import to delivery and payment.

What are container loading inspection services?

Sampling for inspecting during loading of cargo into container

Sampling of goods during container loading is the first important step in the inspection chain of exporting goods,AIM Control (AIM Group®) inspectors will take representative samples according to AQL standards or as required by the public to measure, test, identify, survey, inspect, expertise and control.

Quantitative determination during container loading inspection services

Quantifying consignments is the next step in AIM container inspection process to ensure that the shipment has been produced in sufficient quantities according to the purchase contract.

Determine the quality of goods in the process of container loading

Determining the quality of the shipment during container is verified by AIM Control (AIM Group®) independent inspector to ensure that the product specifications of the purchased and compliance with international standards or national.

Identify packaging labels, marks during the process of container loading

It is important to identify packaging labels, marks on carton, on products to ensure the packages are perfect before delivery to check the labeling, printing of labels, packaging materials, and appropriate packaging specifications according to the requirements of the company. Import company, in accordance with the contract of purchase and comply with transport standards.

Lashing and closed sealing of container loading

-

To be safe in shipping, the lashing and dunnage are suitable for shipping at sea and transportation as well handling of loading, discharging and transits.

-

To prevent of shortage and the criminal action of stealing goods, the doors of container must be closed and sealed under AIM inspector’s witness after container loading is complete.

Certificate / certification / report of container loading inspection services

Before the importing company pays the remaining purchase amount (according to L/C, T/T..) Certificate / certification / report of container loading inspection services attached with the images set.

In addition, the carrier will only accept the exporter's shipment of goods in container to be loaded onboard of the ship having the AIM Control (AIM Group®) Certificate of loading survey and safety cargo inspection.

To be safe for your shipment and prepare to buy (sell), let contact us now!