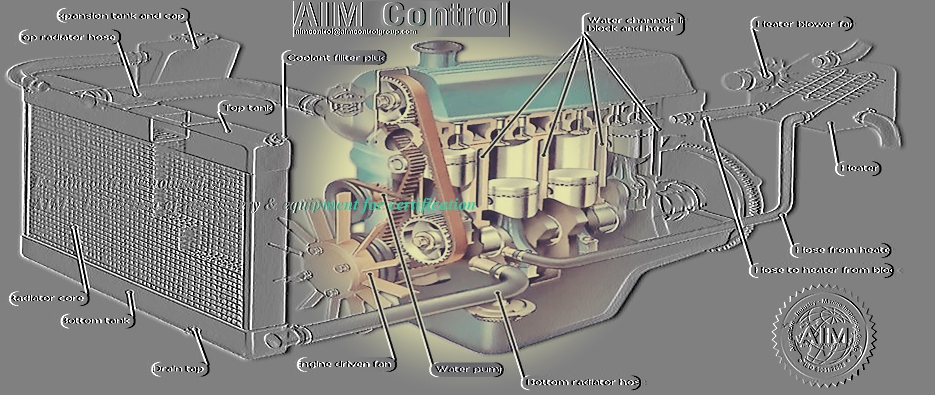

Customs clearance inspection of imported machinery equipment

Customs clearance inspection of imported machinery equipment for certification

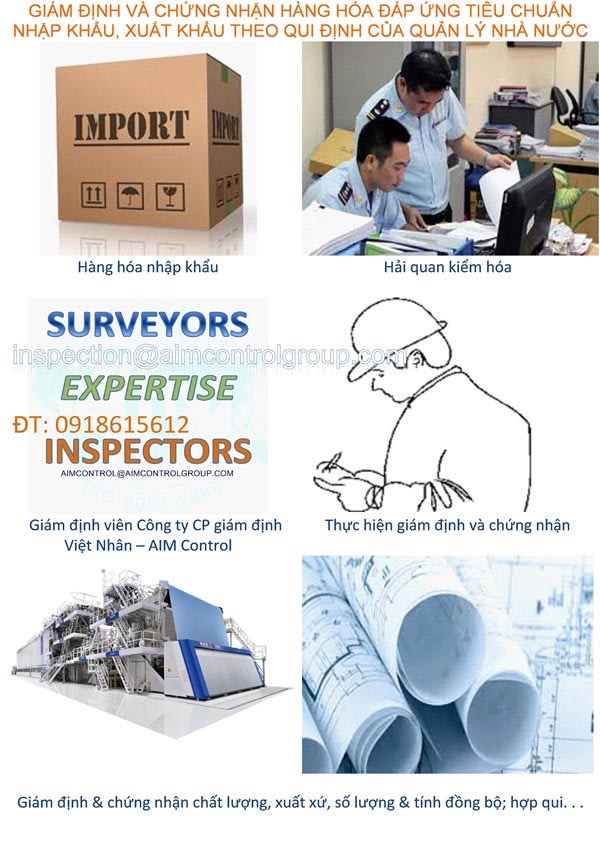

AIM Control (AIM Group®) is approved by The Ministry of Industry and Trade and the General Department of Customs as the company providing services of Customs clearance inspection of imported machinery equipment for certification on condition and function, synchronization for machinery, equipment, production line and manufacturing system are imported or exported in Vietnam, Asia and Global.

Enterprises that require AIM Control (AIM Group®) Certification and Inspection services to import synchronized equipment machinery who need to know the export information, clearance procedures and the provisions of law as followings

Why does the Customs Agency need to "Determine the synchronization of the imported machinery and equipment system"?

-

Most of machinery, equipment and production line systems are either in unassembled condition or have to be disassembled and packaged to shipping and importing into Vietnam.

-

Re-determining of the imported machinery and equipment in comparison with the system’s Type and Function operated in accuracy to the declared by the importing company. (Name, type, brand, model, country of manufacture, year of manufacture, quality (new, old), signs of fixing, erasing or replacing labels and year of manufacture)

-

Approving of the result of HS code

-

Customs clearance for the imported machinery and equipment system under 10 years of age (years of use = at fabrication year – at year of import)Customs clearance for the used technology lines are imported into Vietnam if the remaining quality of the machinery system is over 85%

-

However, if the enterprise is operating in production at Vietnam, to in order to ensure the production activities are maintained, there is a need to import the used machinery and equipment which it’s age more than 10 years with the Rules and Law is prescribed that the remaining quality of the machinery system must be over 85% in comparison with the original design in brand new and the consumption of raw materials, materials and energy of machinery and equipment does not exceed 15%. In this case, the enterprise shall submit 01 set of dossiers of application for import permission sent to the Ministry of Science and Technology for consideration and licensing to getting the approval before import

-

The list of imported goods in the form of disassemble system is too big, so importing enterprises (investors, goods owners, ...) have to import many shipments (shipping to import into Vietnam by many other shipments), enterprises must apply for "Import Permit" for customs authorities to monitor and manage the application of customs clearance.

-

Be refused the customs clearance for the used machinery, equipment, technological lines exported from countries that have been declared discarded due to backwardness, poor quality which may cause environmental pollution or fail to meet the requirements. safety requirements, energy saving, environmental protection

-

To prevent machinery, equipment and technological lines from being exported from other countries to shift/mobilize to Vietnam for investment in order to take advantage of Vietnam's Origin to export It to third countries for the purpose of enjoying policies on tariff preferences or tax evasion

-

Preventing commercial fraud (importing additional accessories)

Main services of Customs clearance inspection of imported machinery equipment for certification

-

Inspection services of the Condition and Function of goods and Certification.

-

Inspection Service of the synchronism for the machinery, equipment system and production lines

-

Service of Certification and Customs Clearance for export and import goods

-

Quality Inspection Service and Quantity Inspection for imported and exported goods and products

-

Inspection Service for Temporary import for re-export of goods

-

Inspection Service for the Residual Value of machinery equipment and production lines before export

-

Inspection and Certification Services for State Administration Agencies

-

Inspection and Certificate of imported and exported goods

Customs clearance inspection of imported machinery equipment for certification is not applied to machines, equipment and technological lines in the following cases

-

Transiting of goods in import and export business

-

Temporary import/re-export

-

Border gate transferring of goods (the goods imported into Vietnam without submitting of the Customs clearance) is the import of a consignment from one exported country to another, without customs clearance into The imported country.

Transshipment of goods is carried out in the followings:

Goods transported directly from exporting countries to importing countries without going through Vietnam's border gates

Goods transported from an exporting country to an importing country through a Vietnamese border gate but without carrying out procedures of customs clearance for importing into Vietnam and for re-export from Vietnam

Goods transported from an exporting country to an importing country through a Vietnamese border gate and be stored into bonded warehouses, transshipment areas at Vietnamese ports, without carrying out procedures of customs clearance for importing into Vietnam and for re-export from Vietnam

-

The imported machinery and equipment are NOT a complete structure, including details, parts interconnected to operating according to the designed system

-

The technological line is a system of machines, equipment, tools and devices installed and NOT jointed continuously at one place location of premise according to diagrams and technical drawings of a set technology system. designed, ensure the synchronism operation for production or manufacturing.

-

The age of the imported machinery and equipment system is over 10 years [the time (in years) calculated from at the year of new building to at the year of importation].

-

Rules and Legal only allows the import of the used machinery, equipment or the technological lines that directly manufactured output the products in Vietnam.

-

Enterprises must submit "Certification of the new build Year and Standards" of machinery and equipment system to be issued by manufacturers in meeting the criteria specified in Decree No. 69/2018 /ND-CP. The Certification must be consular legalized and accompanied with a Vietnamese translation.

-

In some cases, the inspection and certification must be carried out at the exporting country.

The main content of AIM’s Customs clearance inspection of imported machinery equipment for certification

-

Inspection on the technical specifications of machinery and equipment in system

-

Inspection of maintenance process of machines and equipment with checking of procedures

-

Identifying the level of safety standards, energy saving and environmental protection.

-

Verification of OUTPUT capacity (will be calculated by the number of products production by machinery and equipment in a unit of time)

-

Inspection of consumption of energy as fuels, electrical powers and ability to utilize raw materials of system in comparison with the brand new

-

Inspection of circle live of machinery and equipment.

All related information, please kindly invite the customers to contact AIM company as soon as possible for Consulting!