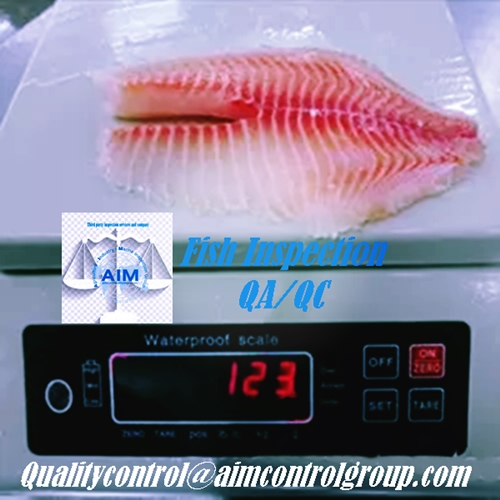

Fish fillet quality control inspection services

Fish fillet quality control inspection services

The fish fillet is one of frozen foods used human therefore in merchandise trading, the frozen fillet of fish must be inspected as Fish fillet quality control inspection to assurance of health and safety

Quality control of fish and fishery, seafoods

Quality control is defined as the assessment of a current operation, in the case of fish and fishery products, quality control includes the steps taken to protect the quality of the material since catch till it reaches the consumer.

Quality is commonly thought of as degree of excellence.

Most Fish fillet quality control inspection is applied by the processor in the fish industry, Government, Enterprises and Traders

AIM Control (AIM Group®) fish inspectors and laboratories

Quality inspection and quality assurance for fish and fisheries

-

Quality Inspection Certification of fish and fish products requires sampling and sensory assessment of freshness and quality at the landing sites, during processing, storage or prior to shipment.

-

Fish freshness control using the Quality Index Method

-

Organoleptic checks (smell, look, texture)

-

Grading (A, B or C) based on fish and seafood quality.

-

Tests to identify residues of heavy metals, histamines and biotoxins.

-

Process control with a glazed/deglazed test and drip loss test

-

Also to prevent the fraud in trading of fishes food.

but the catcher also can exercise some control over quality of the raw material on their fishing boat, at fish manufactories.

Fish fillet quality control inspection on fish Freshness

To inspect and control on Fresh fish or Spoiled fish, the fish inspectors of AIM Control (AIM Group®) activities and roles

-

Odor

-

General aspect

-

Rigidity of the body

-

Secretions

-

Scales

-

Skin

-

Eyes

-

Gill-cover

-

Gills

-

Abdomen

-

Anus

-

Viscera

-

Vertebrate Column

-

Flesh

-

Others

Fish fillet quality control inspection of raw fish, gutted fish Stored in Ice and Outer Appearance

AIM Control (AIM Group®)

-

Freshness, allowing distribution, if kept in ice

-

Reduced, freshness, allowing for regional or local distribution if kept in ice

-

Unfit for human consumption, sometimes limited consumption after frying

Sensory inspection of the quality of finished products (whole or dressed fresh or frozen fish)

This method of fish grading applies to whole or dressed fish, whether fresh or frozen, of any species suitable for use as human food and processed and maintained in accordance with good manufacturing practices. It is based on the standards and codes of practice for fresh and frozen fish.

Product forms

Fresh or frozen fish and fish products can be presented dressed-eviscerated, head- on or headless, with or without fins, skin-on scaled or unscaled or skinless. Frozen fish can be presented individually or as solid packs, glazed or unglazed.

Other products forms are acceptable as long as they are distinct from the previous ones and their production complies with the sanitary regulations.

Sampling and samples

Any fish lot presented for inspection will be sampled according to the sampling plan of AQL levels of inspection I or II (or 100%). (The sampling plan will be used in the case of re-inspection)

Each sample unit will made of the container's content, except when the content exceeds 10 kg of whole or dressed fish or fillets individually or block frozen.

In this case, single fish or fish fillet will random represent the sample unit.

Defects

Defects of whole or dressed fresh or frozen fish are of three types:

Tainted fish: if more than 10% of the declared weight of the sample unit is (or under Contact / PO)

-

Rancid

-

Abnormal because of specific and persistent non characteristic odors or flavors

Decomposed: if more than 10% of the declared weight of the sample unit.

-

presents a persistent, distinct and non characteristic odor or flavor such as ammoniacal, fecal, fruity, hydrogen sulphide, moldy, putrid, salted, milky, chalky, sour, cabbage, yeasts

-

presents a discoloration characteristic of spoilage

-

presents broken flesh texture, as indicated by a tough, dry or spongy muscular structure, or in the case of whole or dressed fish, by the presence of holes in the abdominal cavity or broken belly because of enzymatic activity.

If more than 10% of the declared weight is either tainted or decomposed.

Unwholesome:

-

the presence of critical foreign materials (materials not from fish and that can present a health hazard for the consumer, e.g., metal, glass pieces,…),

-

the presence of distinct and persistent odor or flavor of any matter foreign to the fish but that threatens the consumer health (petroleum, solvent,…) is a threat for the health of the consumer.

-

The presence of other defects such as:

-

Dehydration (freezer burn): more than 10% of the declared fish or fillet

-

Two or more parasites (nematods, copepods) in 3 pounds of flesh or the presence of parasites per sample unit depending upon the size of the unit (1 parasite/2 lbs., 2 parasites/5 lbs., 4/10 lbs., 6/15 to 16.5 lbs., 7/18.5 to 20 lbs., 17/ 50 lbs.)

-

Bones (boneless fish products only): any bone with the largest dimension

-

equal or greater to 5 mm.

-

Undesirable parts such as viscera, heads, tails,… which are not normal parts of the presentation and represent more than 10% of the net weight of

-

the sample unit, making the presentation offensive.

Method of examination

-

Determine the net weight (before and after thawed).

-

Examine fish for the presence of dehydration by measuring %

-

examine of foreign materials, undesirable parts or parasites.

-

examine the entire for odor, color and texture

-

(During re-inspection, if in doubt, the sample shall be cooked to check

-

Determination of grade

-

Storage of fish raw materials

-

Quality of trimmed fillets

-

Corection of weight / sizes

-

Corection of labeling

-

Temperatures of finshed products

-

Aquaculture criteria

-

Identification of Critical control point (CCPs)

-

Tests of Toxins

-

Others

Inspection services of fish quality at all stages

-

Source of fish raised

-

Source of fish caught

-

Source of processed fish

-

Fish source is packaged

-

Fish source is exported

-

Source of fish is imported

-

Sources of fish transported (ships and containers)

in harvesting, in handling, in processing, in packaging, in store, transportation ^& shipping, and distribution based HACCP.

Purposes

AIM Control (AIM Group®) fishery quality control inspection services are to

-

Improving quality

-

Protect customers and consumers

-

Increasing of competiveness

-

Integrated management

-

to prevent the fraud in trading of fishery and fish’s food.

-

To solve the claim and dispute

Other activity :

- Quality inspector

- Face Mask Quality Control Inspection

- Timber Wood quality inspection

- Crude and refined oil cargo test and inspection

- Boat Yacht quality inspection and discharging loading survey

- Consumer Goods quality assured inspection

- Zinc Oxide quality inspection and loading discharging supervision

- Freight Inspection of transport goods

- Product quality inspection

- Certification and Commercial Inspection Services