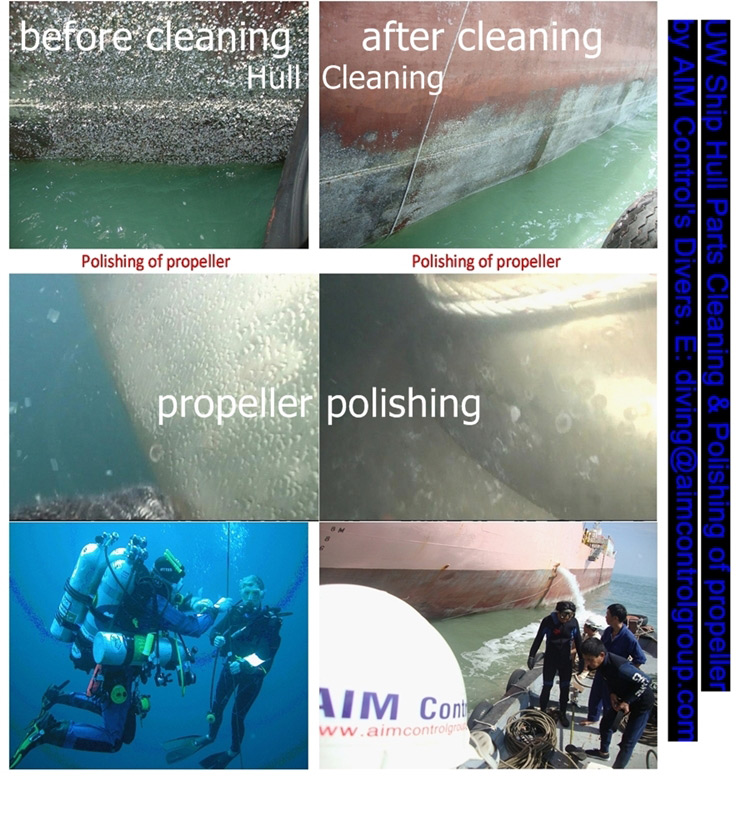

Hull Cleaning

Hull Cleaning Propeller Polishing

The hull cleaning propeller polishing services are underwater works to maintain the vessel parts in water in lieu of dry-docking at the shipyard.

The different cleaning methods depending on antifouling coating type and marine fouling type

The cleaning equipment and devices that will effectively remove the fouling to avoid excessive antifouling paint wear

Hull cleaning includes cleaning of flat bottom, vertical sides, sea chests grids rudder and all niche areas such as bilge keels, dock keel blocks

See more AIM’s vessel hull bio fouling solution and treatment

Cleaning of Ship Hull

Cleaning of vessel's hull is settle to plan for water area and period. The paint/coating system of ship must be protected in UWHC JOB, once fouling starts to build up it is near impossible to pin point.

AIM Control (AIM Group®)

A buildup of marine fouling such as barnacles or tubeworm can cause turbulence, cavitation and noise, affecting the performance of sonars, speed logs and other hull mounted sensors.

Most of our clients therefore combine the vessel’s performance CCTV and inspection survey in-water on the hull coating and fouling before underwater cleaning for hull, this purpose to review the painting system covered and the decision to arrange for cleaning can be worked.

The cleaning of hull and propeller polishing service can result in a hugely positive impact on a vessel’s hydrodynamic performance and fuel consumption.

Propeller Polishing

AIM Control (AIM Group®) propeller polishing service is to reduce the surface roughness caused by the build-up of marine fouling. A smooth propeller surface is inhospitable to marine organisms and enhances the efficiency of the propeller, in turn optimizing the vessel’s performance.

Propeller polishing is arranged the planned intervals or vessel performance but as a rule of thumb, period of 06 to 12 months (depending upon vessel size, trading activity and location) are standard and one of the most common and regular in-water activities.

Underwater survey of condition and measurement services

AIM Control (AIM Group®) have a dive partners who are approved by all classification societies to conduct underwater inspections and surveys.

We can also enable dry dock extensions in lieu of dry dock survey, damage assessments and hull paint/fouling inspection

See AIM’s measuring stern shaft wear UWILD for ship in diving inspection for class

Repairing / Welding / Renew parts of ship in water

Sometimes, the ship owner also needs to temporarily repair for the hull after an accident to voyage to the shipyard for the official repair or to replace some devices for the ship instead of docking of yard. (in emergency)

Environment and Authority

On global fouling UWHC and polishing compliance regulations of national ports

In some water entry are prohibited by port's authorities due to the impacted environment.

Hull and all parts cleaning in water for ship at finished

Hull amd all parts cleaning above water line for Vessel at finished

Propeller polishing cleaning in water at finished