Inspection of product inspection

Inspection of product inspection services

International Quality Inspection of product goods commodity inspection services

In international trading business, usually buyers and sellers in two different countries, so to control the quality of goods, they need a third party inspection AIM Control (AIM Group®) to perform quality inspection of product inspection services

AIM Control (AIM Group®) International is a group present in all countries and territories to meet the requirements of inspection of product inspection services.

AIM Control (AIM Group®) has ISO-qualified laboratories rooms to perform quality tests of products for all types of goods and commodities in commercial production and trading.

Our Independent and Professional team of quality inspectors, auditors and QC who perform accurately and scientifically all Jobs of quality product inspection services to customers.

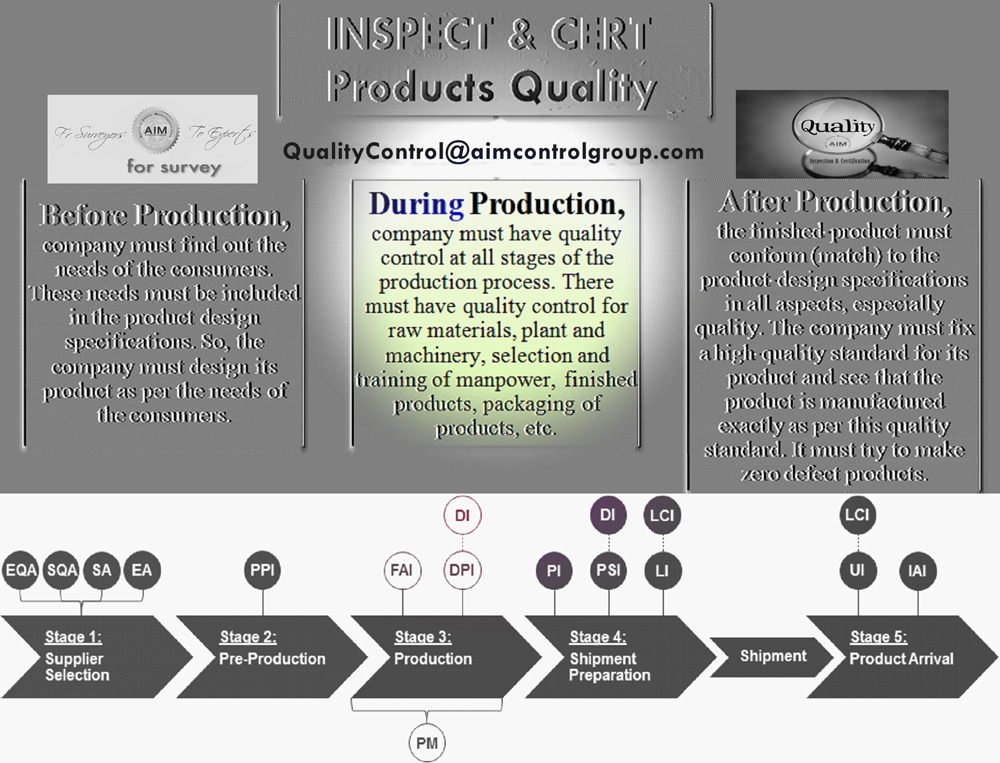

Three main Jobs of Inspection of product inspections

Product inspection services in AQL and Standards / Manufacturing process quality inspection of products & goods

Product testing and inspection on QUALITY conducted at different stages of the manufacturing process helps customers ensure production, safeguard product quality in satisfactory and good, and protect your rights in the country of manufacture.

From the service of auditing the quality of the tailor's factory, inspecting and consulting the design of product code, controlling the quality of materials that will be used to manufacture products and goods; control of production processes; inspection of the first manufactured product, monitoring of defects and defective products according to the ISO and AQL standards or the foreign trade contracts/ POs; the monitoring and inspection of the quality and quantity of shipments being manufactured or processed in continuity (without interruption); the completed product inspection service of shipment after output at factory; inspection of quality goods before delivery.

There are many quality inspections of product and commodity for manufacturing process as followings

AIM Control (AIM Group®) inspection and testing plan and certification services for products at supplier’s premises consisted of (not limited)

-

Production Factory audit

-

Designed product controlling and management

-

Materials of product sampling and tests

-

Production inspection

-

Quality defects of products inspection and rejecting

-

Fabrication quality control and surveillance

-

Final production products inspection services (FI)

-

Quality products pre-shipment inspection services (PSI)

-

Loading inspection services of goods (LS)

-

Tallying of quantity and sealing services

-

Customs clearance inspection of products and goods

-

Inspection of origin of products (Certificate of Origin)

-

Quality inspection of product names

-

Phytosanitary Certificate of products inspection

-

Inspection of product categories (HS Code)

-

Certificate of Conformity / COC inspection (a CoC is a mandatory document for Exports)

-

Charterer engineering certificate (CE inspection)

-

Health Inspection of product and Certification

-

Sampling and Testing at laboratory and at vendor of site

-

Inspection of product constituents (specification)

-

Defective control and management

-

Report and Certification

-

Others

Product inspection services in AQL Standards General Standards of AIM Control (AIM Group®) uses not only the ANSI/ASQ Z1.4- as its sampling standard and acceptable Levels but also compliance with international and government standards.

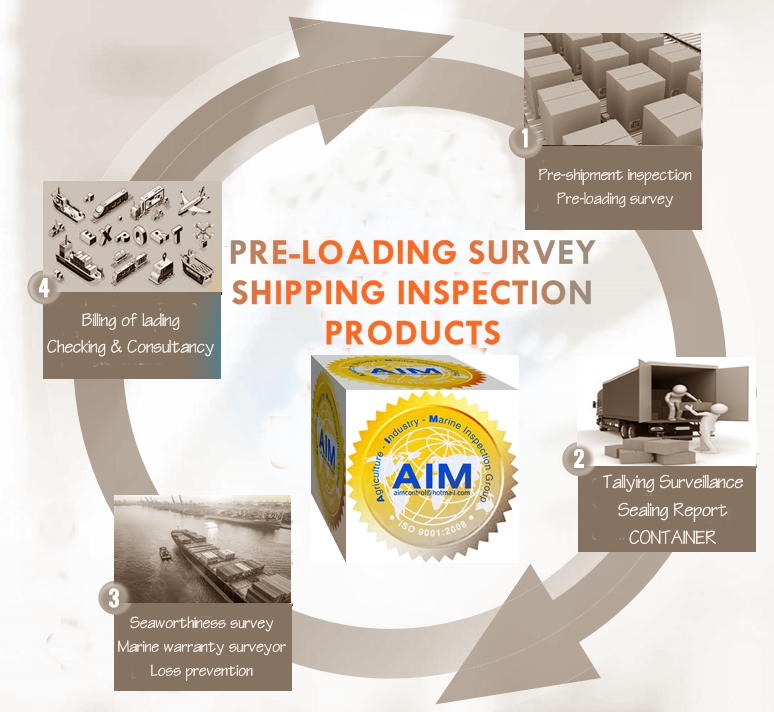

Pre-loading survey, shipping inspection of products

AIM Control (AIM Group®) provides the pre-loading survey, inspection of product and shipping control for Batches of goods and products in international trade must be protected and in accordance with the packaging and shipping process from country seller to destination of buyer.

-

Pre-shipment inspection of products for packing, random quality products in cartons

-

Pre-loading survey for condition physical and packages on pallets

-

Loading supervision and lashing consulting

-

Volume inspection / Weight of products checking / shipment control

-

Quantity survey and inspection (Tallying of quantity or weight of products and goods during being loaded into containers and transport vessel for shipping)

-

Handling stowage surveillance and control

-

Sealing and securing (trucks, wagons, doors of container, cargo holds of vessel, and etc)

-

Container inspection before loading of products or goods

-

Ship’s Cargo holds condition survey before loading of cargo on board

-

Seaworthiness survey and approval

-

Marine warranty surveyors

-

Loss prevention inspection services

-

Risks control and management for shipping

-

Sampling and Testing

-

Condition of products /cargo survey services for advices on Master receipt

-

Billing of lading checking and consultancy

-

Report and certification

-

Others

Destination quality inspection of products & goods

In the transport of goods and products are traded from the loading port of export to the unloading port of import, there are always a lot of risks that may be caused various damages or losses of the shipment.

In order to tracks on the cause of damage to the shipment as well as to valuation the quality of the damaged goods, statistics on the amount of weight and quantity of goods missing or shortage from in comparison with the original, AIM Control (AIM Group®) will provides for Customers with damage survey or/and loss inspection services for cargo and products at the destination port of destination or warehouses of receiver

-

Pre-delivery inspection and survey services

-

Discharging quality inspection of products and cargo

-

Unloading quantity tallying and supervision

-

Damage inspection of cargo / goods on shipment

-

Loss inspection of products for International Trade

-

Cause damage survey for claim insurance (or carriers)

-

Extent of damage valuation for negotiating and compensation

-

Dispute surveillance of products for Attorney, Court, Government and etc.

-

Risks accident / incident surveying

-

Loss adjusting and investigation services

-

Insurance inspection and survey services

Others

REDUCING THE QUALITY RISKS / ADVICES FOR CUSTOMER WORLDWIDE