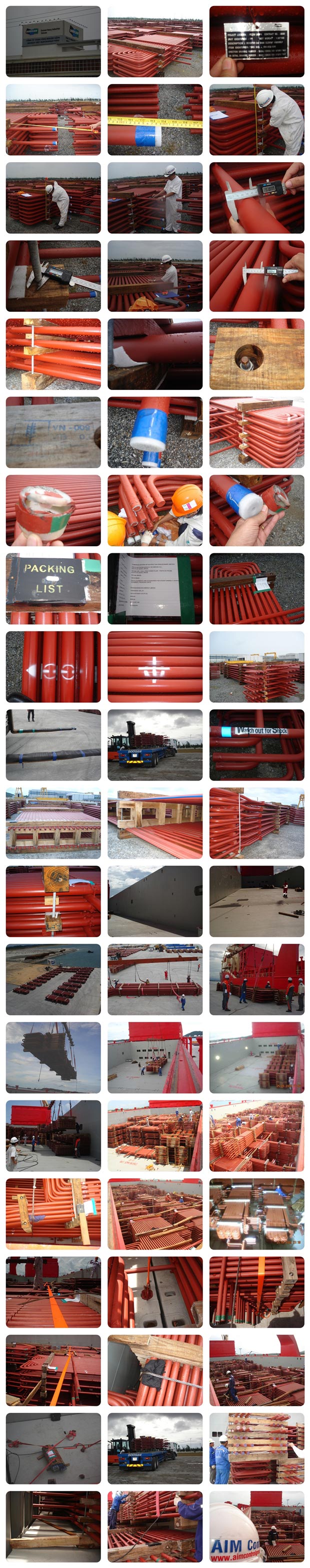

Lashing and securing inspection survey supervision

Lashing and Securing Inspection Survey Supervision services

Heavy lift cargo/ Supercargo loading, lashing and securing inspection survey supervision services are to check condition of cargo, checking the condition of packing and packaging, quantity tally, dimension & size cubic measurement (for packages), monitoring to the loading operation into transportation (vessel, ship), certification, assessment, verify, certify, inspection, identify monitoring to lashing, securing of project cargo, packages together each and into monitoring to and related activities aimed at preventing to damage and / or loss caused to the goods before loading time and during loading period at vendors and ports. Email: aimcontrol@aimcontrolgroup.com

Incidents & Accidents involving transportation can be attributable to inadequate lashing securing for cargo in shipping.

AIM Control’s Lashing, packing & crating surveys:

1. Cargo lashing survey on board vessels.

2. Cargo lashing survey on all type of containers (F/R, OT, GP containers).

3. Car lashing and securing inspection

4. Packing and Crating control.

5. Oil Rig packing inspection and consultancy

6. Multi wrapping cargo inspection

7. Crane, haulage, jacking and skidding survey

The loading & lashing and securing inspection survey supervision services also carried out to calculate and consultancy for heavy-lifting equipment and data of the goods from manufacturing plant to port yard, shore to ship (container) before loading or pre-shipment.

AIM Control (AIM Group®) lashing and securing surveyors are marine warranty experts as loading master, port captain, cargo surveyor and maritime consultant, . .who have highly experienced in shipping over 50 years sailed and surveyed for same goods and fluent IMO, SOLAS, regulation as code of safe practice for cargo stowage and securing to administration of client's requirements.

The cargo can be loaded and stowage into cargo holds, on deck, into flat rack, open side, open-top containers . . .the calculating of lashing is importance, therefore AIM Control (AIM Group®) surveyors have approved license meet with an international standards and expertise in identify all of latent risks can be caused loss / damage for goods as well fill in & fill out.

During the monitoring process, AIM Control (AIM Group®) knowledge consulters will give timely advice when them realize there are possible risks to the goods. That latent to be processed immediately.

When ocean vessel voyage, her condition is in heavy sea and bad weather conditions. AIM Control (AIM Group®) qualified and experienced securing surveyors always anticipate the effects of cargo shifting to calculate of lashing for suitable.

The loading, lashing and securing inspection survey supervision experts review on cargo compartment, ship type and her structure to calculate on handling, stowage for stability.

Some basic elements in AIM Control (AIM Group®) stowage securing and lashing survey are as heavy lift crane, heavy lifts, improper stowage, inadequate packaging, lashing device, lashing point, lashings, marks and numbers, cautionary markings, cause of loss. metric ton, pallet, shifting, shock damage, nature of loss, edge damage, distortion, discoloration, dirty cargo, cosmetic damage, compression damage, dew point, ventilation, marine liability, shoring, shortage, skid, said to contain (stc), stowage, stowage pattern, edge protection. dunnage, straddle crane, watertightness, waterproofing, hazardous, capacity, grab, general average statement, deck line, deadweight, deadfreight, cubic, cube, crushing, cargo sweat, ship sweat, condensation, centre of gravity, ballast, draft . . .

The incident or accident report will be made immediately under jointed witness and signature.

AIM Control (AIM Group®) marine & cargo surveyors also carried out the surveying general cargo, are unbiased third party who provides professional expertise on the condition, value, suitability, insurability, and/or extent and cause of damage on marine property for shipper, charterer, carrier, buyer, seller, forwarder & logistics, an ship-owner, underwriter, P&I Clubs, or others interested party in professional global.

Loading and Lashing and Securing Inspection/ Survey/ Supervision loading supervision provided by AIM Control Inspection Group at all of ports worldwide.

AIM Control (AIM Group®) heavy lift cargo and supercargo loading survey is carried out to avoid problems such as wrong goods shipped; wrong quantity shipped, damaged merchandise or damaged packaging.

We are providing the loading inspection services, which are performed as followings:

What is exactly loaded on board my ship’s holds?

How to inspect/survey/

How to inspect/survey/

How to inspect/survey/

How to inspect/survey/

What to inspect/survey/

-

The loading inspection covers quality verification, the quantity checking, the packing list checking, survey to condition ship’s holds, supervision to the process of the loading (cartons/packages conditions) and also a quick inspection on selected sampling size to check the workmanship, main functions, capacity of ship’s crane, capacity of forklift, checking to packaging and packing, checking to tags name, markings, checking to condition of loaded sling, checking to lashing belt capacity, checking to tags name, measurement of sizes.

-

Check packaging (inside and out) for physical damage

-

Check all quantities of merchandise

-

Perform a random Quality “spot-check”

on the merchandise -

Record the seal number and departure time of ship’s holds

-

Weather, truck forklift, forklift, sling, lashing material etc…

-

Supervise lashing, securing, dunnage

-

Record the incident and accident to goods, packages if having any damage

-

Record the time sheet of loading

-

Collect the document of B/L, Certificates. . .

When to inspect/survey/

With the Vessel/Ship (SLS), loading survey is also called Ship Loading Supervision, will take place right before the PORT and STEVEDORE is supposed to load the goods into the holds of ship/vessel and also during the loading process.

Where to inspect/survey/

- At the ports or anchorage or buoying (for ship, vessel)

Purpose of lashing securing inspection survey supervision services are to

safety for goods during transportation.

On AIM Control (AIM Group®) heavy lift project cargo inspection, measurement and lashing & securing survey