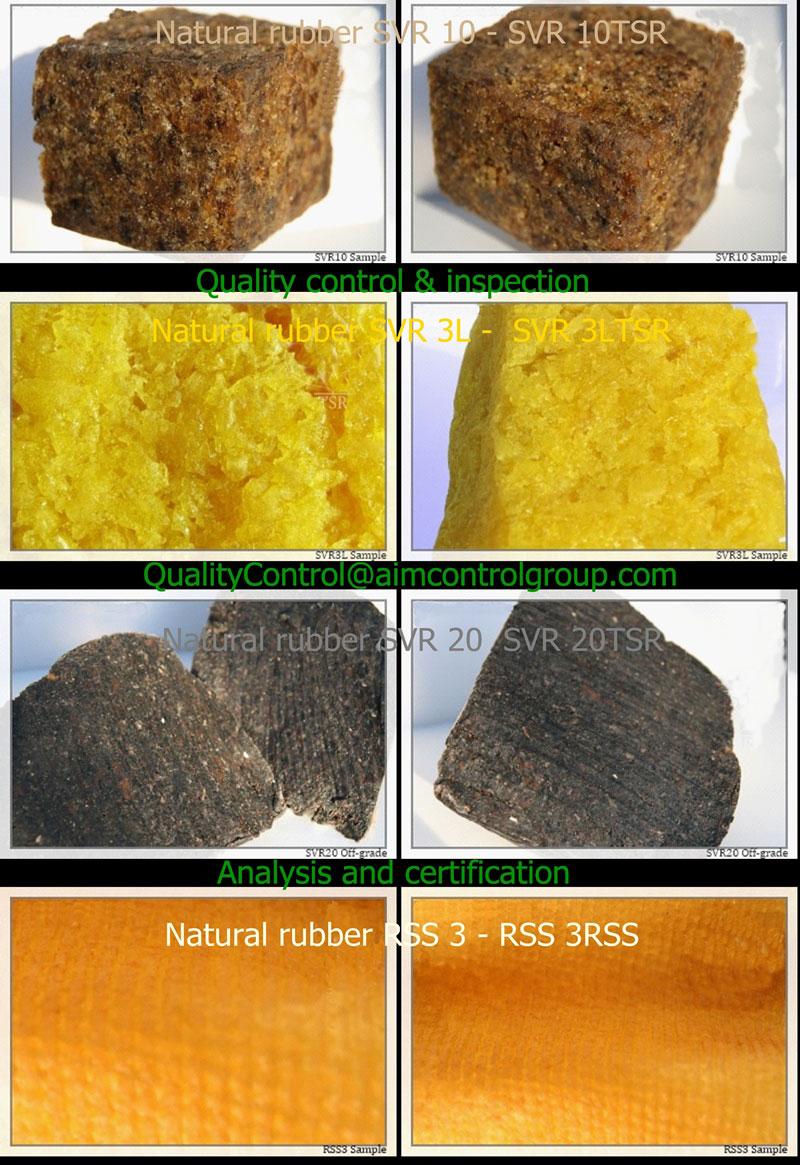

Natural rubber product inspection

Natural Rubber Product Inspection

Natural Rubber is Raw Materials

AIM Control (AIM Group®) carrying out each natural rubber product inspection job consisted of dimensional inspections. visual inspection, weight control, quantity of bale tallying. the natural rubber products are taken a draw samples for analysis to identify specification and issuing ensure quality certificates and inspection reports to meet customer’s specification.

Quality natural rubber product control:

AIM Control (AIM Group®) offering natural rubber product inspecting includes controlling on a range of technically specified natural rubbers. they are manufactured to worldwide industry standards and batch tested to comply with ISO.

There are six different grades of technically specified natural rubbers.

However, major rubber producing countries follow their respective national standards as SMR is Standard Malaysian Rubber, STR is Standard Thai Rubber, SRV is Standard Vietnamese Rubber.

Analysis and Testing requirements between different national standards are understandably similar

The followings tables in the "Specification" of Natural Rubber on its quality differences

AIM Control (AIM Group®) has provided professional rubber product inspection services over 0 years, via independent tally-men and surveyors who have a lot of experience in natural rubber products and supplier on pre-shipment inspection, during loading, unloading as well at time of damage / loss for who interest in the exactly natural rubber product quantity to delivery and receiving for shipment container and shipping.

AIM Control's Specification of natural rubber product inspection and analysis and certificate on quality:

-

Dirty (retained on 45µ aperture), (%wt).

-

Ash, (%wt).

-

Volatile matter, (%wt).

-

Nitrogen, (%wt).

-

Initial Wallace Plasticity (Po).

-

PRI (P30/Po) x 100.

-

Lovibond color.

-

Mooney Viscosity

-

ML (1’+4’)100oC

-

Rheometric Cure (160oC, 1o arc 100 rpm, ACS1):

-

Torque Max, (dNm).

-

Scorch Time t2, (m:s)

-

Optimum Cure Time t90, (m:s)

Weigh & Quantity of natural rubber product inspection:

AIM Control (AIM Group®) verify on weight of each natural rubber bales of shipment as well bridge-scale of hug weight on trucks carried bales.

AIM Control (AIM Group®) also determines quantity of piece rubber goods via tallying of natural rubber bale while discharging or loading.

We monitoring strictly on loading / discharging to prevention mistaken and shortage.

And then, we sealing of our seals and witness carrier's seal after loading finhed (or witness breaking of sealing period of discharging)

-

Product Loading supervision

-

Cargo Tally

-

Witness of sealing (or sealing)

-

Cargo Loss Prevention

-

Sampling and Testing, Analysis

-

Third Party Inspection

-

Etc.

In general, the application of the concept of quality control and Inspection for a natural rubber products manufacturing unit for export would consist of:

-

The range of inspection services ensure your goods are safeguarded throughout the purchase/merchandise

-

Receiving inspection - to assure the product/material received meets the required specifications before it is manufactured.

-

In-process inspection (On-going basis)- to assure the parts

-

Finished goods inspection (to ensure any secondary operations are performed to specifications and that product meets all requirements)

-

Issue the weight and quality certification

Also carrying jobs of the natural rubber product expertise on weight & quality claim & dispute Inspection:

-

Pre-Insurance Inspection Services

-

Pre-Purchase Inspection Services

-

Merchandise Inspection Services

-

L/C (Sale Contact) Inspections and certificates

-

Insurance Claim Inspection Services

-

Consignment Loss Damage Claim Control and Survey for buyers

-

Damage Survey and shortage disputes inspection at destination

-

Deviation Cargo Quality Control & Deviation Cargo Certification based the actual to be compared Buy Contract.AIM Control (AIM Group®) conducted the natural rubber product supervision and tally services at the site of loading:

Other activity :

- Quality inspector

- Face Mask Quality Control Inspection

- Fish fillet quality control inspection services

- Timber Wood quality inspection

- Crude and refined oil cargo test and inspection

- Boat Yacht quality inspection and discharging loading survey

- Consumer Goods quality assured inspection

- Zinc Oxide quality inspection and loading discharging supervision

- Freight Inspection of transport goods

- Product quality inspection