Project n Cargo verification services

Project n Cargo verification services

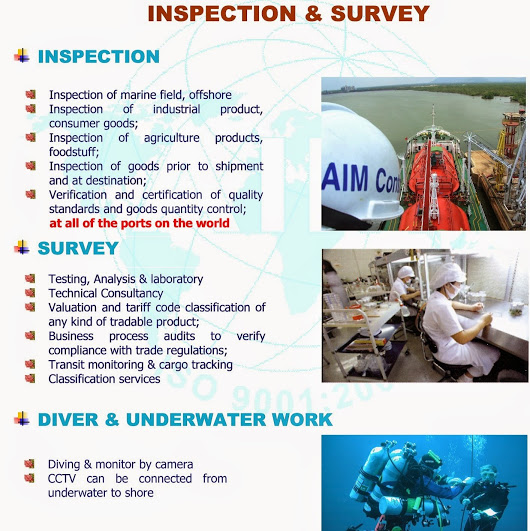

AIM Control (AIM Group®) offers the project n cargo verification services are to inspect the goods, products meets requirements and specifications and that it fulfills its intended purpose to tests, to ensure the accuracy, correctness, or truth of the shipment.

The project n cargo verification report of AIM Control (AIM Group®) sent to customer after actions are in independent, scientific, accurate at site and lab.

One of purpose of project cargo verification actions are to control the deceitful suppliers caused of false to the goods before loading and period of loading.

AIM Control (AIM Group®) is the world’s leading verification companies to offer you accuracy, experienced specialists, the-art examination methodologies. By a result of certification, we can help you ensure that your products, services and processes follow the national and international standards – wherever you are in the world. Email

Regarding to the goods are exported, AIM Control's cargo expertise controller providing based on quality controls, inspections, verifications, identification, measurement, weighing, testing, sampling & analysis, also called pre-shipment inspection (PSI) on goods before loading; loading supervisions, tally of quantity, witness of sealing for containers and to issue the Certification of Verification/ Inspection (COI).

Kind of goods and object verification services

An important aspect about the goods to be exported is compulsory quality controls and pre-shipment verification that are prerequisite for exporting goods. under the export (Quality Control and Inspection) Act, International, about 1,000 commodities under the major group of: Food and Agriculture, Fishery, Minerals, Organic Chemicals, Rubber Products, Refractory, Ceramic Products, Pesticides, Light Engineering Steel Product, Jute Products, Coir and Coir Products, Footwear and Footwear Products/Components, manufactories and vendor factories.

Place / local of verification of cargo: at the supplier's premises, port of loading, place of loading, vendor factories, manufactories at countries of exporting of goods and anywhere.

Period of goods verification services: before open L/C (as factory verification), period of production (quality monitoring), final production inspection before loading and quantity control period of loading, at the time of sealing witness, supervision, tally survey.

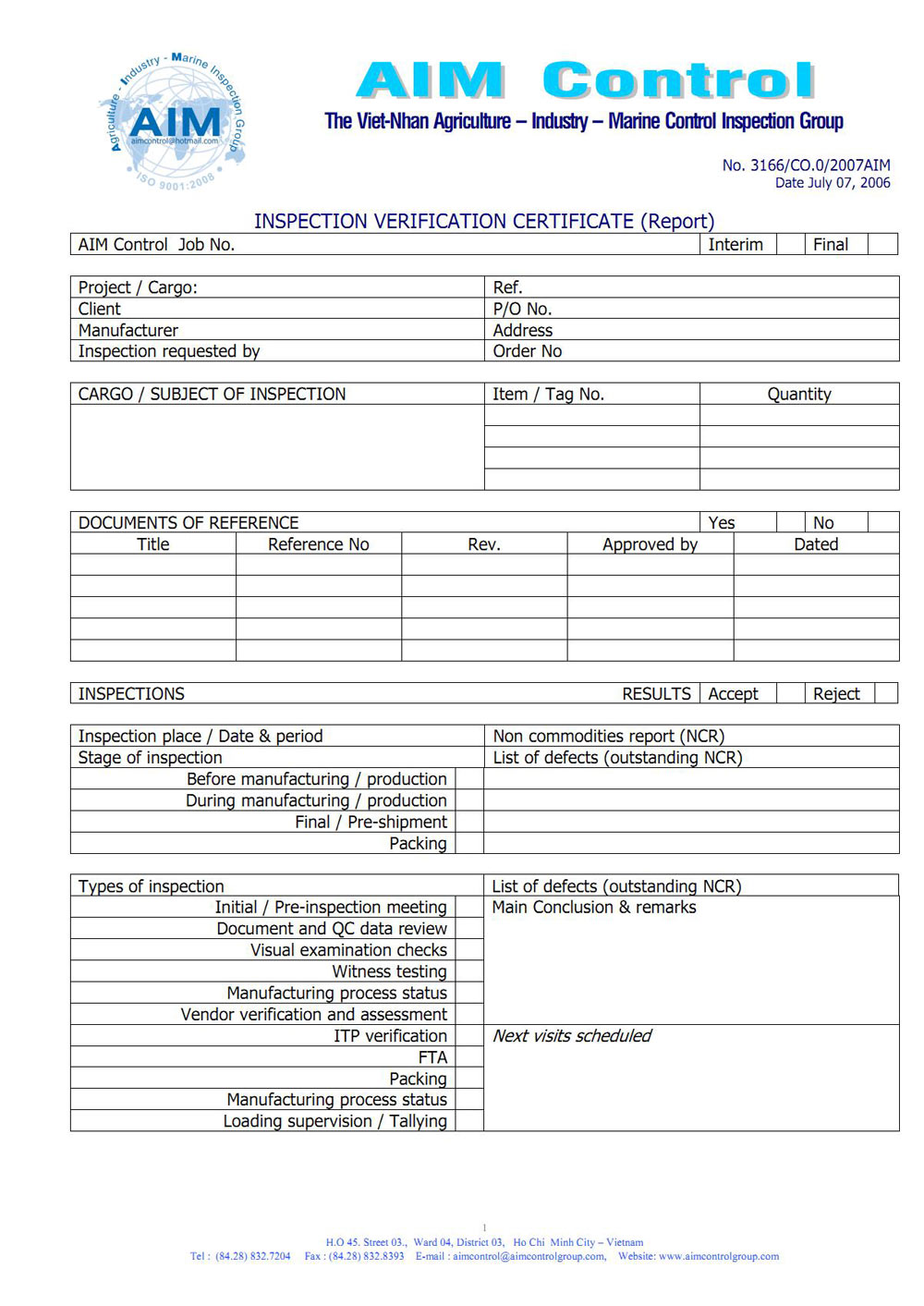

Cargo Verification Certification (CVC): after verifications completed, AIM Control (AIM Group®) will issue the Certification of Inspection to you (results) and photos (the evidences).

Sometimes overseas buyers lay their own standards/specifications of goods which may or may not be in consonance with the international standards. They may also send their own nominated to AIM Control (AIM Group®) Inspection Group to provide verification services.

To provide the cargo verification services in time for consignment to consignment, Customer send the information to AIM Control asap, before the expected date of shipment of the consignment and at address of survey, the premises of the exporter, or at the port of shipment.

After satisfying itself that the consignment of exportable goods meets the requirements stipulated in the export contract/order, AIM Control (AIM Group®) issues certificate of inspection to the exporter.

The certificate is issued in the standardised form which is aligned pre-shipment export document. (Three copies for exporter, original copy for customs use, the second copy for the use of the foreign buyers and the third copy for the exporter's use, fourth copy for Data Bank, Export Quality control/Inspection Council, and the fifth copy is retained with the AIM Control Inspection Group).

Export quantity quality project n cargo verification services act, international

The Export quantity and quality cargo inspectors is who responsible for the operation of this Act. Under the Act, a large number of exportable commodities have been notified for compulsory quality control/ pre-shipment inspection of various export products is administered through worldwide network of AIM Control's offices at located.

Documents required for quality controls & verifications of cargo

AIM Control (AIM Group®) good manufacturing verification services

-

Copy of commercial invoice

-

Copy of Letter of Credit

-

Details of packing specifications

-

Copy of the export order/contract, indicating inter alia the buyer’s requirement that goods are strictly according to the prescribed specifications or as per samples

AIM Control (AIM Group®) Inspection Group Vietnam & Global has performed supplier audits of pharmaceutical suppliers for quality conformances and compliance to FDA standards and required GMP practices. We worked with some of the best medical devices manufacturers to validate compliance to specifications and usage safety consistencies.

GMP is also Best Manufacturing Practices. BMP driven customers have employed AIM Control (AIM Group®) Inspection Group Vietnam to initiate supplier risk management programs.

AIM Control (AIM Group®) Inspection Group Vietnam customer driven GMP and BMP supplier programs include:

-

review and validate good production documentation practices

-

investigating, documenting and correcting deviations from normal

-

manufacturing and customer business compatibility

-

visiting key suppliers to validate resources for production boost

AIM Control’s production verification services

Many quality problems begin at the production sources. Random final Quality verification and controls/ inspections do not minimize the problems and delays in delivery for our customers. AIM Control (AIM Group®) Inspection Group Vietnam provides you a Supplier Production Surveillance format to collaborate with your Supplier’s manufacturing processes.

Aside from process auditing, our SQE can,

-

maintain technical verification and surveillance of work-in-progress.

-

verification and identify defective parts and assemblies and sources of supply

-

verification and monitor the interchangeability and substitution of components

-

correlate the interrelated modifications of assemblies and parts

-

evaluate the tolerances checks and production cycles.

AIM Control’s In-Process quality verification services

In-Process quality verification and inspection by an AIM Control (AIM Group®) Quality Representative is the selective inspection & verification of the product/components/subassembly at different stages of the production line. This is carried out when the product is in current production. In-Process Quality Verification Inspection is customer mandated and focuses on specific objectives:

Find the root causes of production defects detected during final Quality verification & control/inspection. In-Process Quality Verification can be used by the customer with the objective of reducing on-going 100% Quality control/inspection of all production lots. It can be used with other AIM Control (AIM Group®) Supplier Quality Controls and Verification Services to bring the supplier into a state of Supplier Quality Self Control.

-

Verify the execution of Corrective Action Report (CAR) by the Supplier Production Team.

-

Inspect and identify and detect poor quality linkages at different production stations.

-

Product and component quality verification and inspection before assembly.

-

Identify supplier production weaknesses in the production system that leads to defects.

AIM Control’s Pre-delivery Verification services

-

When was the last time you bought a shipment of garbage?

-

AIM Control (AIM Group®) Inspection Group provides customers with inspection services that will eliminate unexpected supplier product and quality surprises.

is a way of verification sure you get what you expect from the supplier, means getting an inspector to do a check & verification on what is being loaded into the container, what is in the boxes, and that it works. if you are a trading operation that buys a variety of consumer or simple products and consolidates your shipment, a quick 1-2 days pre-shipment inspection on your goods to verify the supplier’s obligations to you is probably what you need to prevent your losses

The PSI or FRI (Final Random Inspection) should take place when at least 80% of the production is reached and packed into export cartons.

This Quality control/inspection covers: product appearance (AQL), workmanship quality, size measurements, weight check, functionality assortment, accessories, labeling & logos, packaging, packing and other tests and special requirements, depending on the product and the export market.

AIM Control's team of inspectors chooses a specific quantity of completed products - quantity according to - and inspects them according to your specifications, requirements and according to our protocols and expertise.

After completion of the inspection, a fully detailed Quality control/inspection report with pictures and comments is sent to you. Then you are able to Accept or Reject your shipment online.

In case of a failed inspection you should consider using our and ask for a Re-inspection. For some tricky shipments you might also consider a full carton/ products Quality control/Inspection. We also help you to find solutions with your supplier.

AIM Control’s Loading verification services

-

This is the finished step to control quality and quantity of shipment before exporting.

-

Ship, Transportation, Container’s condition survey

-

Tallying of quantity (control of quantity during loading)

-

Sealing of container's doors (witness after loading completed)

Import quantity quality project n cargo verification services act, international

Other activity :