Quality Gloves Inspection

Quality Gloves Inspection

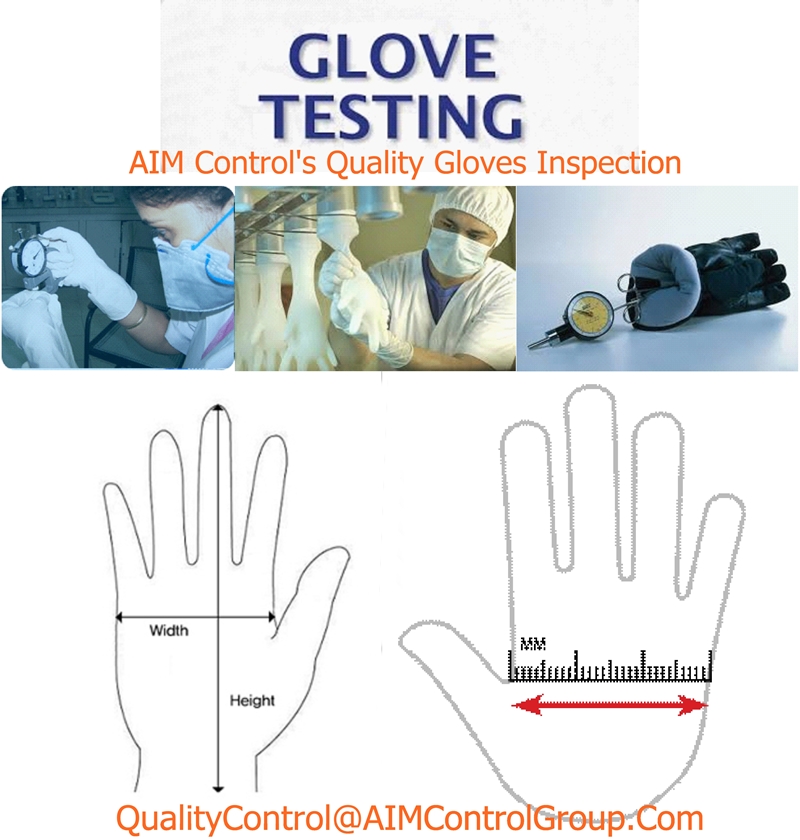

AIM Control (AIM Group®) quality gloves inspection is quality control, pre-shipment inspection (PSI) and loading supervision to non-sterile latex powdered examination gloves and other materials including cloth, knitted or felted wool, leather, rubber, latex, neoprene.

The gloves standards are European Committee, ASTM & ISO on specification as freedom from holes, dimension, physical, leach protein, powder residue, powder amount, shelf life. AIM Control conducts quality control and inspection for production of gloves via AQL 1.5 - 2.5 (or as per client's approval).

Quality Gloves Inspection on testing

-

Testing of gloves on freedom from holes used water at 1000 cubic cm under observation during 2 to 4 minutes

-

Testing of gloves on physical property used force at break with sampling S 2 & AQL 4.0 level unaged and aged, cutter width at 3mm to 4 mm.

AIM Control (AIM Group®) quality control & pre=-shipment inspection, loading supervision and tallying of quantity on the Non-sterile Latex Powdered Examination Gloves and Leather Gloves Products quality control at the Supplier factory carried out by our inspectors, surveyors in India, China and Malaysia:

-

Sampling of Gloves products ( for testing on quality control and pre-shipment inspection)

-

Conducting Tensile strength and Elongation Test in Lab on Gloves (quality control and pre-shipment inspection)

-

Powder level testing Gloves (quality control and pre-shipment inspection)

-

Filled gloves observed for leaks Gloves (quality control and pre-shipment inspection)

-

Twisting & Squeezing the gloves to check Gloves (quality control and pre-shipment inspection)

-

Phytosanitary inspection and certificate (quality control and pre-shipment inspection)

-

Tally of quantity of Gloves products were completely fabricated until time of inspection on-site (loading supervision)

-

Verifying the Shipping Mark, Packing, Carton condition of Gloves products (quality control and pre-shipment inspection)

-

Verifying the Label, tags of Gloves products (quality control and pre-shipment inspection)

-

Verifying the sophistication of Gloves products (the seam, neatly, regular, symmetrical . . .) (quality control and pre-shipment inspection)

-

Verifying condition of packaged inner and outer carton/ bags/ pallets of Gloves products (final inspection)

-

Dimension measurement (thinness, sizes) (quality control and pre-shipment inspection)

-

Weight checking (quality control and pre-shipment inspection)

-

Moisture testing (quality control and pre-shipment inspection)

-

Function testing witness (quality control and pre-shipment inspection)

-

Material of Gloves products and appearance of products identifying (quality control and pre-shipment inspection)

-

Checking to find out the defects of the Gloves products (quality control and pre-shipment inspection)

-

Checking to identify the specification of the Gloves products as per P.O. (quality control and pre-shipment inspection)

-

Checking to identify the specification of the products as per buyer’s pattern samples. (quality control and pre-shipment inspection)

-

Checking to identify Hazard Analysis and Critical Control Points (HACCP) (if having requirement). (quality control and pre-shipment inspection)

-

Container's condition inspection before loading (loading supervision)

-

Tally of packages of Gloves during loading (loading tally)

-

Witness and checking Sealing/ Number (loading supervision)

The followings photos are evidence of AIM Control's quality gloves inspection at the site

The videos of AIM Control (AIM Group®) taken at the site of control and inspection, survey before packing at supplier premise and loading supervision and quantity of carton tallying for Non sterile Latex Powdered Examination Gloves product: