Quality inspection

Quality Inspection

There are many factors that make up quality!

Each type of product (or commodity as well as people and nature) makes a difference in Quality.

There are many different types of quality for each individual product

Quality Inspection of AIM Control (AIM Group® is only one factor contributing to product quality at "initial/process/end/final".

A quality inspection involves measuring, examining, testing, or gauging various characteristics of a product and comparing those results with specified standards at time of inspection and Laboratory.

Quality Inspection has a "tolerance" for several reasons:

-

experience of quality inspector

-

sampling method

-

period of inspection

-

cooperation between the parties

-

deviation of measuring machinery and tools

-

deviation in action / activities

-

deviations in sampling equipment, sample containers

-

quality inspection procedure, process and report

-

others

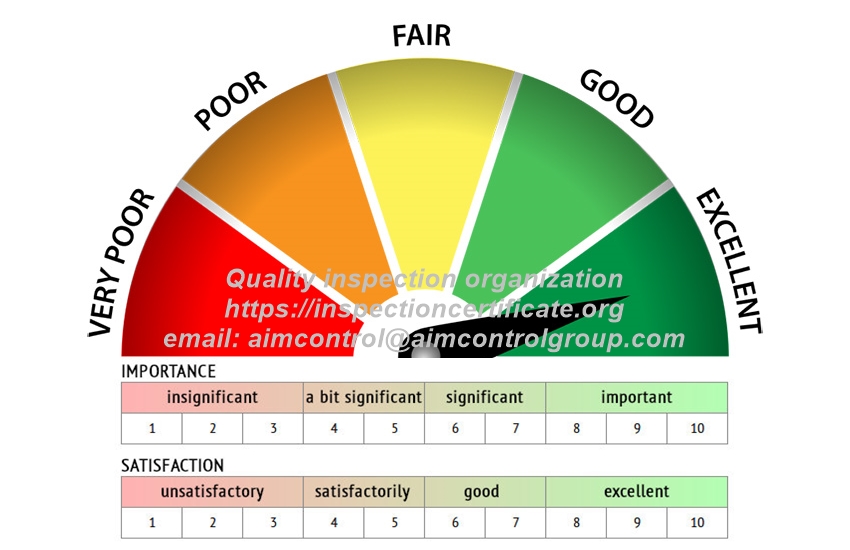

Quality score scale:

Each type of product (new or used) has its own quality scale, the quality score is usually a factor of 1 to 10.

There are some other Quality score like

-

right or wrong

-

pass or fail

-

in defect or in sound

-

imperfect or in new with perfect

Here are some basic elements that form quality:

-

Project quality inspection?

-

Product quality inspection?

-

Types of Inspection and quality control?

-

Quality inspectors?

-

Quality controllers?

-

Quality controlling?

-

Quality tests?

-

Quality materials?

-

Quality certificates and certification?

-

P.O with international and specified standards?

-

Quality manufacturer / factory?

-

Quality Assurance?

-

Quality manufacturing / process?

-

Quality fabrication / production?

Explanation:

Project quality inspection?

Project quality inspection is the monitoring and control of a manufacturing process for a project with many different products manufactured and assembled into a system.

Product quality inspection?

Product quality inspection is the monitoring and inspection of a manufacturing process for one or more similar products manufactured and packaged in a single shipment.

Types of Inspection and quality control?

For project:

For product / cargo / others:

-

Sample Checking

-

Pre-Production Inspections (PPI)

-

During Production Inspection (DPI)

-

Pre-Shipment Inspection (PSI)

-

Piece by Piece Inspection (or Sorting Inspection)

-

Metal Detection

-

Final inspection

Quality inspectors?

Quality inspectors are a person or a team with specialized experience and qualifications for the inspection of a specified product or project.

Quality controllers?

Quality controllers? is a person or team with experience, specialized qualifications of a manufacturing plant or outsourced by them for the purpose of quality control of a product, project or process management.

Quality control (QC)

Quality controlling is a process through which a business seeks to ensure that service or product quality is maintained or improved. Quality control involves testing units and determining if they are within the specifications for the final product.

Quality tests?

Testing is the process or activity of testing the functionality and structural components of a product or project against specific requirements in order to confirm the quality and reliability of the system.

Quality materials?

Quality materials are in initial input essential for quality results; hand in hand with quality inspection, quality materials provide a sturdy and durable construction and structures as well others.

Quality Certification - Quality Certificates?

Quality Certification is a general term that is used for Three main things:

-

certifying the knowledge of individuals

-

certifying a company's system of quality management

and 3.

-

Quality material certification

-

Quality testing certification

-

Quality analysis certification

-

Calibration Technician certificates

-

Device certificates

-

GMP Professional certificates

-

Quality inspection certification

-

Quantity and weight survey certification

With individuals as:

-

Quality Auditor certificates

-

Quality Engineer certificates

-

Inspector certificates

-

Food Safety and Quality Auditor

-

Manager of Quality certificates

Etc.

P.O with international and specified standards?

A standard purchase order is typically used for irregular, infrequent or one-off procurement. it contains a complete specification of product or project in the purchase, setting out the price, quantity and timeframes for fabrication and payment and delivery.

International Standards contain technical specifications or other precise criteria, which ensure that materials, products, processes, services, systems, or persons are fit for their intended purpose.

International standards are one way to overcome technical barriers in international commerce caused by differences among technical regulations and standards developed independently and separately by each nation, national standards organization, or business

The government often draws on standards when putting together legislation or guidance documents. Standards are used to establish the technical detail, allowing the legislation to concentrate on long term policy objectives

Regulatory Standards means all standards, rules and regulations promulgated by a Regulatory Authority and applicable to the product and the manufacture thereof, including without limitation cGMP.

Quality manufacturing?

At its most basic level, manufacturing quality is conformance to specifications. Quality of design and conformance to specifications provide the fundamental basis for managing operations to produce quality products.

Quality assurance?

Quality assurance can be defined as "part of quality management focused on providing confidence that quality requirements will be fulfilled." The confidence provided by quality assurance is twofold—internally to management and externally to customers, government agencies, regulators, certifiers, and third parties.

Quality fabrication / production?

Cutting, punching, forming, shearing, stamping, welding are common fabrication techniques used to shape, cut, or mold raw metal material into a final product. Fabrication is distinct from other manufacturing processes

In manufacturing, a measure of excellence or a state of being free from defects, deficiencies and significant variations. It is brought about by strict and consistent commitment to certain standards that achieve uniformity of a product in order to satisfy specific customer or user requirements.

As the leader of "third party quality inspection", with more than 50 years of experience and knowledge, AIM Group will serve customers to satisfaction in any situation.