Fibers and plastic materials quality inspection and certification

Fibers and plastic materials quality inspection and certification I Inspections on scrap materials

AIM Group inspection and certification organization provide the services of Fibers and plastic materials quality inspection and certification on global for customer in goal with the main procedure steps

-

AIM Group Inspection Overview

-

Inspection timeline

-

Inspection Data

-

Summary of Requirements

-

Loading Photos

-

Bale-face Photos (1 per bale)

-

Data Submission & Reporting

-

Summary of Requirements

-

Uploading data to Google Drive

-

Inspection Report

-

Appendix

-

Rejection criteria for bales

-

Loading photos: photo of each layer loaded

-

Moisture readings (Fibre only)

AIM Group Inspection Overview

Inspection timeline

Inspector briefing (prior to inspection day)

Inspection details shared, including a link to upload data & report forms to be filled in following inspection.

Pre-loading / Pre-shipment

1. Arrival on-site ahead of first scheduled loading

Check-in with site contact and complete any required inductions

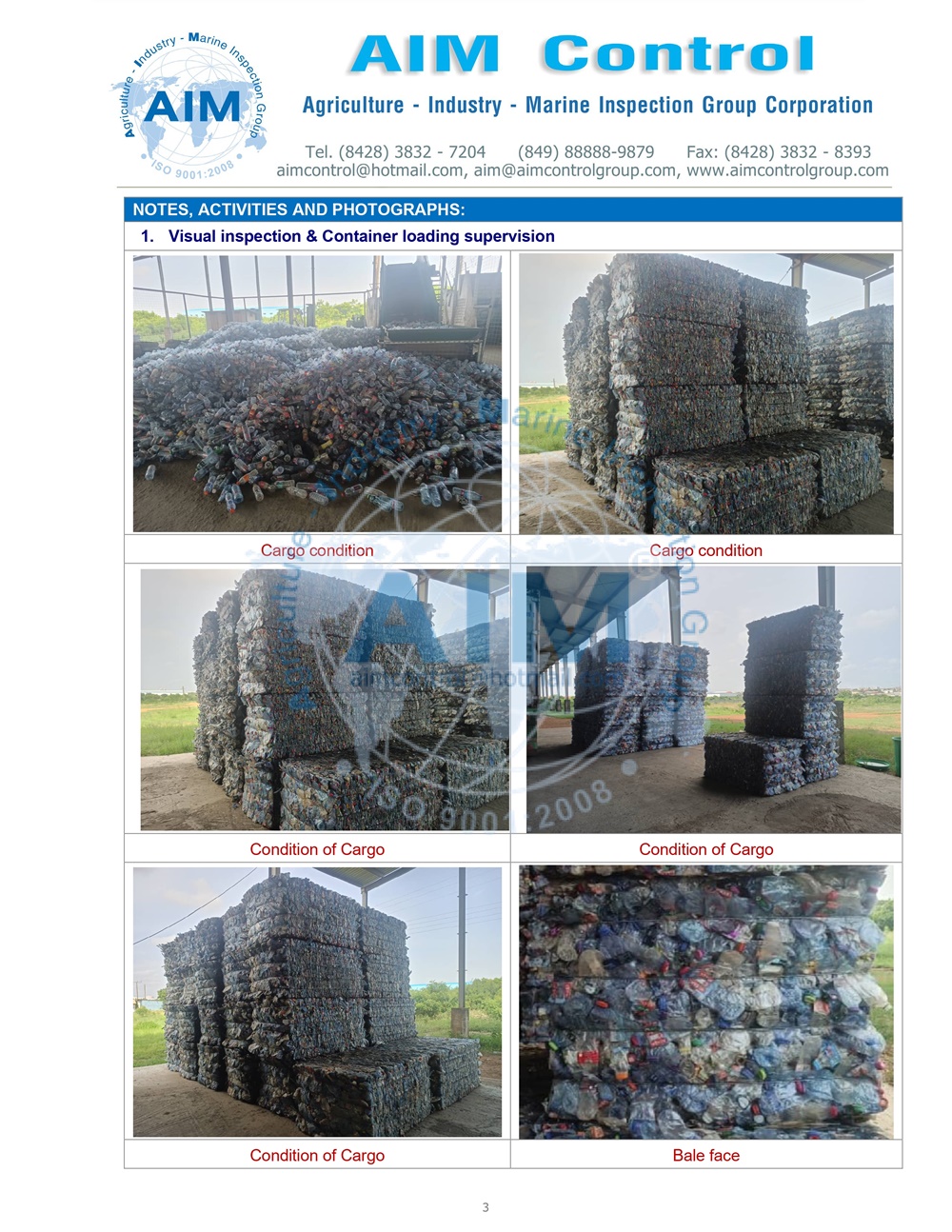

2. Initial assessment of material to be loaded

Identify material for today’s loading and check it meets the required quality and grade specification. Take clear pictures, as evidence.

3. Bale break and analysis

Select a single bale to break. Video the bale-break. Take photos of the broken-up material focusing on the impurities that can be found

4. Inform site whether or not loading can go ahead

During Loading

5. Loading data collection and bale rejection

5a. Take loading photos

5b. Take images of every bale during loading - this includes rejected bales

5c. Reject bales during loading that are not up to standard

Post-loading

6. Upload all data through link provided

To be completed within 2 working days of inspection.

Inspection Data

Summary of Requirements

Listed below are the pictures (& video/s) that should be collected during an inspection. This data provides evidence of being present at the inspection & shows that the material meets the quality requirements.

Pre-loading

● Picture of Surveyor holding a sign with the deal number

● Pictures of the material on-site in storage

● Video of one bale broken per 5 loads

● Fiber grades only: moisture readings (see Appendix for specific requirements)

During Loading

● Standard loading photos* - as evidence that the material that has been quality-checked is the same as the material that has been loaded

● Single picture of each bale*, including rejected bales

*These requirements are covered in more detail in the following sections.

Loading Photos

The required loading photos will be different depending on whether a container or curtain-sider is being loaded.

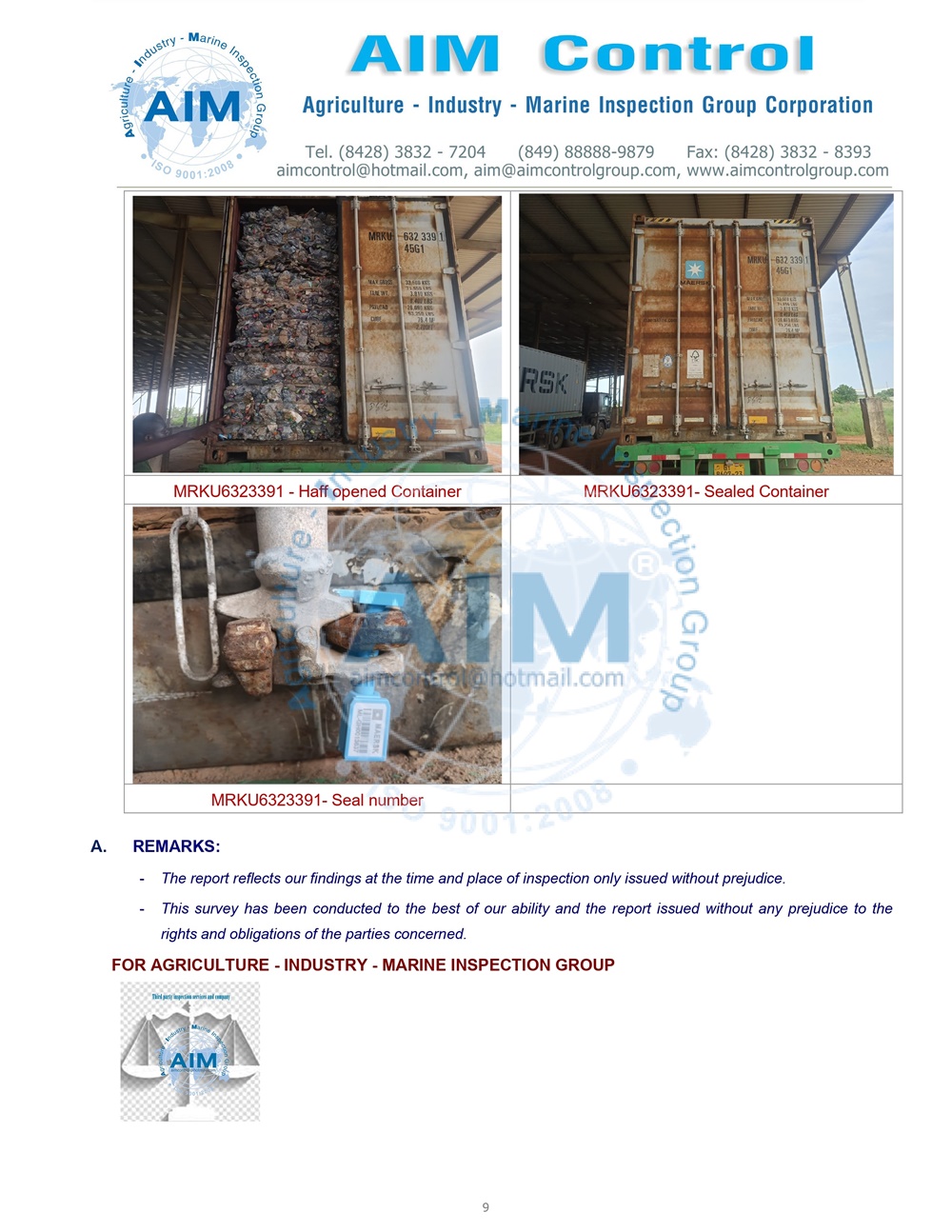

Container loading

● Container, when empty, prior to loading

● Empty container with the right door closed (with container number visible)

● A picture of each loaded ‘layer’ of material e.g. if there are 7 layers that make up a full container, we require 7 pictures, including layers 1/7, 2/7, 3/7 4/7, 5/7, 6/7 & 7/7 (full) - see Appendix for example photos.

● Fully filled container with 1 door open (with container number visible)

● Fully filled container with both doors closed (with container number visible)

● Locked doors with seal (with seal number visible)

● Weigh-bridge ticket, showing final loaded weight

Curtain-sider loading

● Curtain-sider, empty with sides open, prior to loading

● Empty curtain-sider with trailer number visible

● A picture of each loaded ‘layer’ of material (this can be from any angle, as long as all bales in the layer are clearly visible)

● Fully filled curtain-sider from side with trailer number visible

● Fully filled curtain-sider from back with 1 door open

● Fully filled curtain-sider with both doors closed (with trailer number visible)

● Locked doors with seal (with seal number visible)

● Weigh-bridge ticket, showing final loaded weight

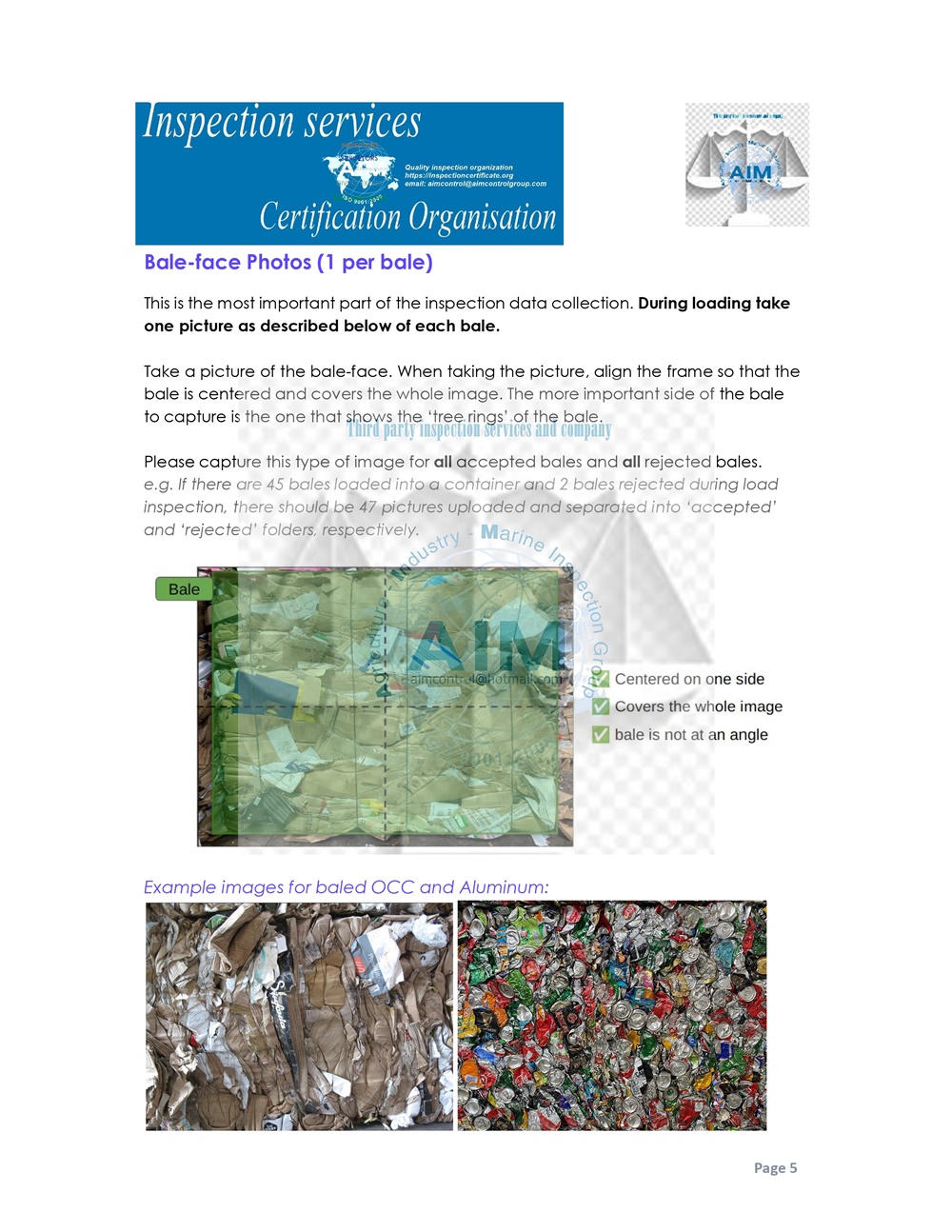

Bale-face Photos (1 per bale)

This is the most important part of the inspection data collection. During loading take one picture as described below of each bale.

Data Submission & Reporting

Summary of Requirements

Following the inspection, the data needs to be uploaded through the link provided and all report forms filled in.

As part of the inspection briefing you will have gotten three things:

● A link to a Google Drive folder to upload all images & videos following the inspection

● An Inspection Report form (included in the Google Drive folder) to complete following the inspection

● A Inspector Briefing Document to inform you of any specific things to watch out for during the inspection

Uploading data to Google Drive

Data Quality

It is important to maintain the full image & video (data) quality when uploading to the folder. The easiest way to do this is to upload data directly from the device (phone or camera) to the folder. If an alternative method is used, please ensure it does not involve compressing the data before uploading.

Inspection Report

Inside the folder there is an Inspection Report form for each load with some basic info to update following inspection, including;

General Information

● Date of Inspection

● Name of Inspector & AIM Group

Container Loading Details

● Net weight

● Container No.

● No. of bales loaded (accepted & rejected)

● Moisture (Fibre only)

Take a picture of the bale-face. When taking the picture, align the frame so that the bale is centered and covers the whole image. The more important side of the bale to capture is the one that shows the ‘tree rings’ of the bale.

Please capture this type of image for all accepted bales and all rejected bales.

e.g. If there are 45 bales loaded into a container and 2 bales rejected during load inspection, there should be 47 pictures uploaded and separated into ‘accepted’ and ‘rejected’ folders, respectively.

Appendix

Rejection criteria for bales

During inspection it is important to judge bales individually rather than to judge the load as a whole. We find that rejecting and accepting material on a bale-by-bale basis is the best way to ensure our quality meets the standards of what was agreed during the sale.

Facilities and recycling materials are always unpredictable so please follow the criteria below as a rule of thumb only. If something feels off or unclear, get in touch with your AIM Group contact and double-check with them.

Material Quality

1. If a bale shows per area more than the accepted amount of contamination on the side (for 95/5 this would be more than 5% of the bale surface showing contamination) then reject the bale.

2. If one of the following is visible on the outside of a bale the bale should be rejected. This has no effect on the rest of the loading.

a. Prohibited substances: Any materials which represent a hazard for health, safety and environment, such as medical waste, contaminated products of personal hygiene, hazardous waste, organic waste including foodstuffs, bitumen, toxic powders and similar

i. Threshold for foodstuffs is as follows: If there is contamination caused by food (E.g. oil residue on a pizza box, grease or fat marks on food packaging) then we do not reject. If there are visible chunks of food (e.g. piece of toast, part of a slice of pizza, vegetables or fruit bits left in fruit box packaging) then we reject the bale.

ii. Personal hygiene products may include used nappies, sanitary towels or similar and if any of these items are identified the bale should be rejected.

Moisture (fibre only)

1. The average moisture content across a load needs to be <12%. We typically accept bales up to 16% moisture as long as there are also bales with 6-8% moisture present. If after loading half of a container all bales have been at 16% or more, stop loading and contact AIM Group inspection and certification organization to discuss how to proceed.

a. If it is possible to inspect the moisture levels of the bales in the yard prior to loading and the same result is visible this is preferred. Again, contact AIM Group inspection and certification organization as soon as it is clear all of the bales are at >16%.

2. We automatically reject any bale with moisture >20%.

Loading photos: photo of each layer loaded

Examples of a picture of each loaded ‘layer’ of material.

In this example, there are 6 bales in a layer and each of the 9 layers that make up a full container have been photographed.

Moisture readings (Fibre only)

Equipment

For accurate assessment of moisture content in fibre loads, moisture readings must be taken with a device designed for use with baled fibre grades and which can probe to a minimum depth of 10cm. Examples of acceptable moisture meters include EMCO AP 500-M2 or Delmhorst P-2000.

Data requirements

Per container, a minimum of 10 moisture readings should be taken. It is usually easier and less disruptive to loading to take moisture readings before loading, from the stacked material in the yard or hanger. If this is not possible (e.g. if the material is not accessible) readings can be taken during loading.

Moisture readings (Fibre only)

Equipment

For accurate assessment of moisture content in fibre loads, moisture readings must be taken with a device designed for use with baled fibre grades and which can probe to a minimum depth of 10cm. Examples of acceptable moisture meters include EMCO AP 500-M2 or Delmhorst P-2000.

Data requirements

Per container, a minimum of 10 moisture readings should be taken. It is usually easier and less disruptive to loading to take moisture readings before loading, from the stacked material in the yard or hanger. If this is not possible (e.g. if the material is not accessible) readings can be taken during loading.

Dr Capt. Nguyen Te Nhan / G.D

Agriculture Industry Marine Control Inspection Group of Companies®

---

E-mail: CEO@aimcontrolgroup.com

inspection@aimcontrolgroup.com

diving@aimcontrolgroup.com

qualitycontrol@aimcontrolgroup.com

tallying@aimcontrolgroup.com

Urgent : aimcontrol@hotmail.com

http://www.inspectioncertificate.org

https://www.aimcontrolgroup.com

Tally Survey Inspection Certification Investigation Expertise Witness

Diving Underwater Clean Warranty & Approval Asia, Global.

Surveyors I Inspectors I Consultant I Tally-men I Divers I Experts

Referring to:

Scrap-metal-inspection-services

Incinerated-steel-scrap-quality-control-inspection

High-quality scrap types requires to remove a low trace element content. Our Professionals can determine scrap quality through the use of grading systems that set minimum and maximum content for specific metal impurities.

In the scrap trading business, commercial fraud occurs frequently and the consequences cause a lot of difficulties for the assessor and surveyors and also a lot of financial loss for the buyer or seller. Therefore, in finding a third-party assessment inspection company with full experience and capacity like our AIM Group is not easy.

For examples:

In Bangladesh,

during a scrap inspection, our inspector was arrested by the receiver simply because he defended the correct survey results and refused signature to "false figures" by the buyer.

In India,

during a scrap unloading inspection, the receiver threatened to beat up our inspector if he did not agree to sign the “false figures” because they wanted to commit commercial fraud to take advantage of the reduced purchase price.

In Nigeria,

AIM Control Group's surveyor had stopped the loading process, because he found out the cargo of scrap plastics were in dirty and a lot of impurities (see more).

In Vietnam,

AIM Control surveyors surveyed and certified the scrap rate of the shipment when unloading the cargo and found that the impurity rate of the cargo was too high. This is evidence of litigation in the international commercial court for the customer.

Asia

Afghanistan Bangladesh Bhutan Brunei Cambodia China East Timor Hong Kong India Indonesia Japan Laos Malaysia Maldives Mongolia Myanmar Nepal North Korea Pakistan Philippines Russian Federation Singapore South Korea Sri Lanka Taiwan Thailand Vietnam

Middle East

Armenia Azerbaijan Georgia Kazakhstan Kyrgyzstan Russia Tajikistan Turkmenistan Uzbekistan Bahrain Cyprus Iran Iraq Israel Jordan Kuwait Lebanon Oman Palestine Qatar Saudi Arabia Syria Turkey U.A. Emirates Yemen

Europe

Andorra Albania Austria Belarus Belgium Bosnia Bulgaria Croatia Czech Republic Denmark Estonia Finland France Germany Greece Greenland Holy See Hungary Iceland Ireland Italy Latvia Liechtenstein Lithuania Luxembourg Macedonia Malta Moldova Monaco Netherlands Norway Poland Portugal Romania Russian Federation San Marino Spain Slovakia Slovenia Sweden Switzerland Ukraine United Kingdom Yugoslavia

Americas

Antigua and Barbuda Argentina Bahamas Barbados Belize Bolivia Brazil Canada Chile Colombia Costa Rica Cuba Dominica Dominican Ecuador El Salvador Grenada Guatemala Guyana Haiti Honduras Jamaica Mexico Nicaragua Panama Paraguay Peru Saint Kitts and Nevis Saint Lucia Saint Vincent and the Grenadines Suriname Trinidad and Tobago U.S.A. Uruguay Venezuela

Pacific

Australia Fiji Kiribati Marshall Islands Micronesia Nauru New Zealand Palau Papua New Guinea Solomon Islands Tonga Tuvalu Vanuatu Samoa

Africa

Algeria Angola Benin Botswana Burkina Faso Burundi Cameroon Cape Verde C. African Rep. Chad Comoros Congo Cote d'Ivoire Djibouti Egypt Equatorial Guinea Eritrea Ethiopia Gabon Gambia Ghana Guinea Guinea-Bissau Kenya Lesotho Liberia Libya Madagascar Malawi Mali Mauritania Mauritius Mayotte Morocco Mozambique Namibia Niger Nigeria Rwanda Sahrawi Sao Tome and Principe Senegal Seychelles Sierra Leone Somalia South Africa Sudan Swaziland Tanzania.