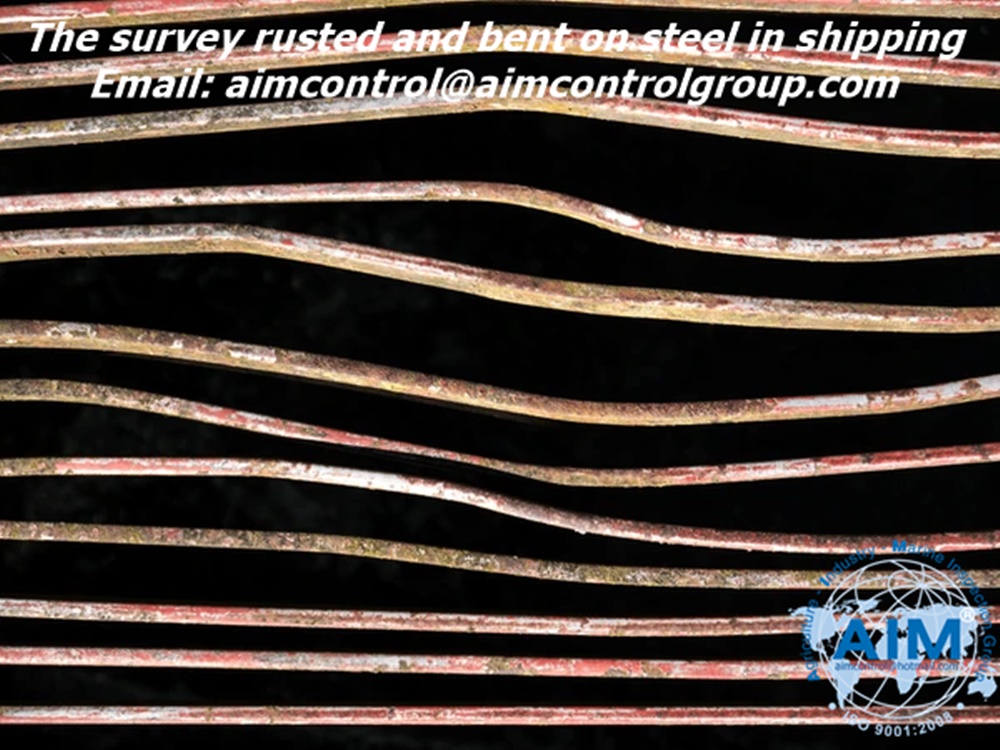

Steel Products Pre-Loading Survey

Steel Products Pre-loading Survey and Loading Supervision services:

An important aspect about the steel (products) to be exported is compulsory quality control and pre-shipment inspection and loading supervision. Quality control, pre-shipment inspection and pre-loading survey, loading supervision are prerequisite for exporting goods aiming loss prevention. Email

Example for Steel Products Pre-loading Survey/ Loading Supervision job of AIM Group:

Information:

-

Name of vessel: MV ...

-

Loading Port: ...

-

Scope of works: preloading and loading survey, tallying.

-

Cargo: XXXXX mt steel (kinds) products

Scope of survey:

-

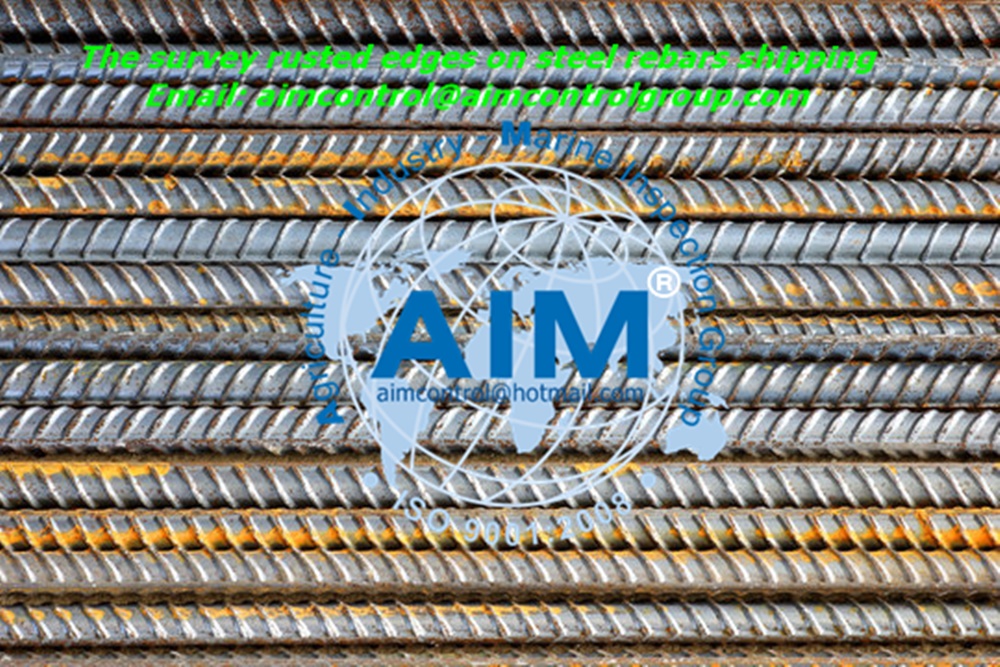

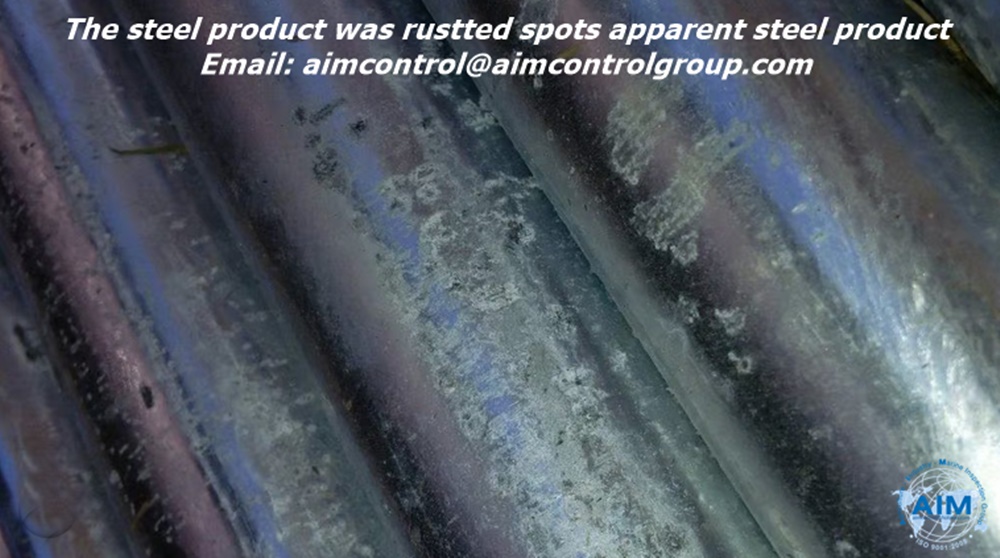

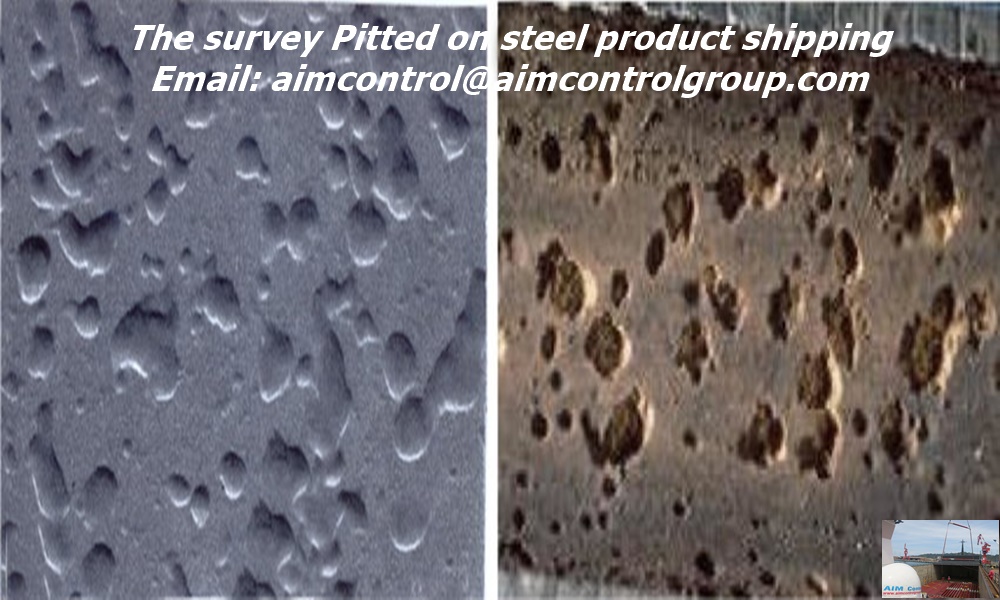

Pre-load survey, cargo condition before loading, ascertaining cargo condition remarks, by each lots including Photographic evidence of their condition prior and during loading on board and noted on your handbook of any defect identified to make the report submit to the Master of the ship daily and final.

-

Silver Nitrate tests should be carried out in order to exclude any affection by chlorides.

-

Verification of tags / quantity as per respective packing lists

-

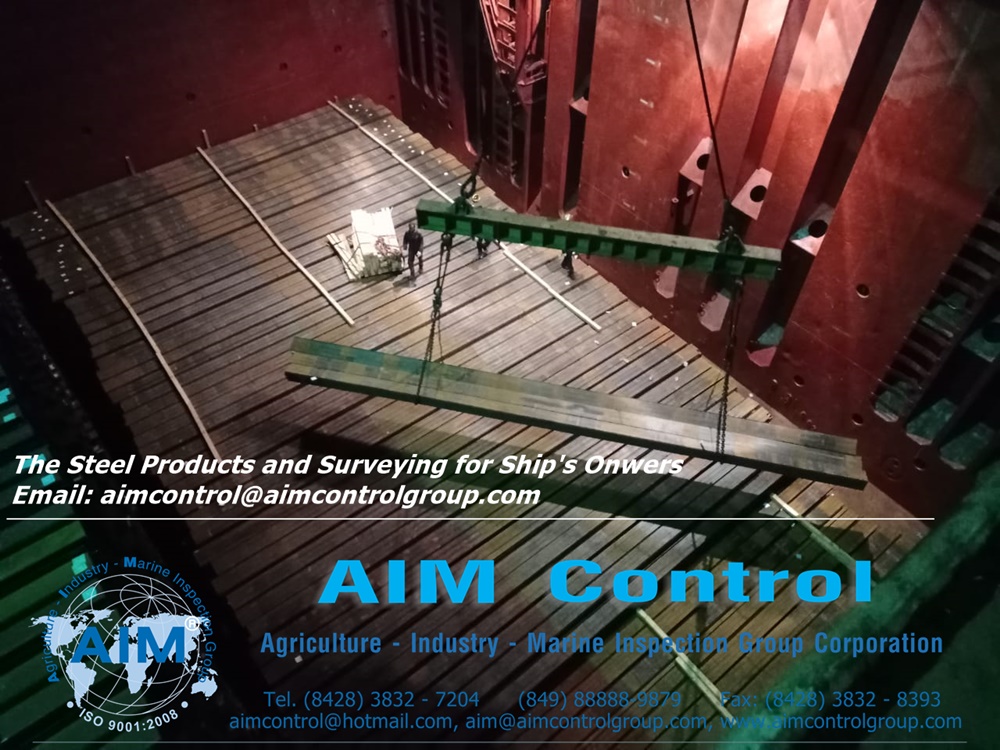

Survey for condition of cargo holds, hatches, hatch covers and loading gear, and general condition of the weather deck

-

Cargo holds water tightness test (By ultrasonic or Hose test)

-

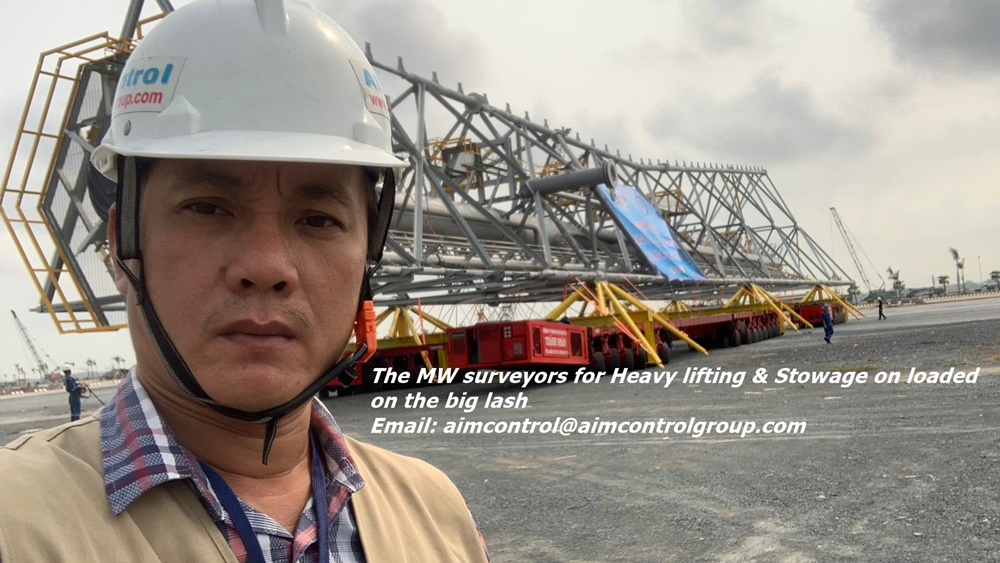

Supervising loading, stowage and lashing.

-

Rendering assistance to the Master to include all remarks related to the cargo condition in the mate receipts / bills of lading. (attached please kindly defects are found into the CARGO CONDITION REPORT for issuing to submit for the ship's Master's singing onboard.

-

Issuing a Notice of Fact/Letter of Protest and/or Damage / Loss survey report in case arisen the accident / incident

-

Issuing Daily report, Final Loading Record / report onboard

-

Issuance official cargo survey certification including photographic evidence as the attached.

Contact point:

To be advised:

If a customer has any issue, pls kindly contact with us asap. We are in 24/24! at email: aimcontrol@aimcontrolgroup.com (WhatsApp: + 84903615612)

See more the pre-loading surveyors

Almost of PNI insurance clubs recommended on their owner and charterer members to AIM Group's pre-loading survey for the low-value and semi-finished steel products carried out.

The insurance company cover may be prejudiced if the master or the policy holder knows that the bill of lading, waybill or other document evidencing the contract of carriage contains an incorrect description of the cargo or its quantity or its condition of steel products and its packing before loading and after loading via AIM Group's survey results report and advices before the master's signature a Mate's Receipt.

A Mate's Receipt is a temporary receipt issued and signed by the officer of a vessel, to acknowledge the goods ready to be loaded on a ship. This acts as evidence that goods were loaded in the vessel but it does not have the same validity as for instance, the bill of lading

Consignees/receivers of cargo are entitled to rely on the description in the bill of lading and may claim for damage or shortage based on description of the order and condition as stated in the bill of lading.

We are AIM Control (AIM Group® in Vietnam and Global, an independent inspectors, surveyors and experts providing inspection services, expediting services, testing, QA/QC, Cargo Survey, Marine survey, Certification based in Vietnam, China, India, Asia, Europe, the Middle East Anywhere of Countries to protect your orders in good condition. Email: aimcontrol@hotmail.com, inspection@aimcontrolgroup.com, cell: +84903615612, www.aimcontrolgroup.com. AIM Control which became an associate member of ASTM, Rolled Steel Org., AISI American Iron and Steel Institution, E & E Steel Company, JISF, the Association of Cold Rolled Strip Steel Producers, American Iron & Steel Institute & AIST.

Sometimes overseas buyers lay their own standards/specifications which may or may not be in consonance with the international standards. They may also upon inspection by their own nominated agencies of AIM Control Inspection Group. These issues should be sorted out before confirmation of order.

Consignment to consignment inspection-under this scheme the application (in duplicate) for inspection for goods has to be submitted well in advance to AIM Control Inspection Group, in the new prescribed form ‘intimation for inspection’, before the expected date of shipment of the consignment. Inspection of the consignment is generally carried out either at the premises of the exporter, provided adequate facilities exist therein for inspection, or at the port of shipment.

After satisfying itself that the consignment of exportable goods meets the requirements stipulated in the export contract/order, the inspection of AIM Control Inspection Group issues, generally within some days of receipt of intimation for inspection, the necessary certificate of inspection to the exporter in the prescribed proforma in five copies.

The certificate is issued in the standardized form which is aligned pre-shipment export document. (Three copies for exporter, original copy for customs use, the second copy for the use of the foreign buyers and the third copy for the exporter's use, fourth copy for Data Bank, Export Inspection Council, and the fifth copy is retained with the AIM Control Inspection Group).

EXPORT (QUALITY CONTROL & INSPECTION) ACT, INTERNATIONAL:

The Export Inspection Council is responsible for the operation of this Act. Under the Act, a large number of exportable commodities have been notified for compulsory pre-shipment inspection. The quality control and inspection of various export products is administered through a AIM Control (AIM Group®) Inspection Group network of more than fifty offices located around major production centers and ports of shipment. In addition, AIM Control Inspection Group may be recognized as agencies for inspection and /or quality control.

Documents required for quality control

There are certain forms and documents that are necessary for quality control and pre-shipment inspection. The following documents need to be submitted along with the application:

(i) Particulars of the consignment intended to be exported

(ii) Copy of commercial invoice

(iii) Copy of Letter of Credit

(iv) Details of packing specifications

(v) Copy of the export order/contract, indicating inter alia the buyer’s requirement that goods are strictly according to the prescribed specifications or as per samples

Good Steel Manufacturing

AIM Control (AIM Group®) Inspection Group has performed supplier audits of suppliers for quality conformances and compliance to standards and required practices. We worked with some of the best devices manufacturers to validate compliance to specifications and usage safety consistencies.

Steel Production Control and Certification at the supplier's manufacturing / facility

Many quality problems begin at the production sources. Random final inspections do not minimize the problems and delays in delivery for our customers. AIM Group® Inspection Group provides you a Supplier Production Surveillance format to collaborate with your Supplier’s manufacturing processes.

In-Process Steel Product Quality Inspection

-

In-Process steel Quality Inspection by an AIM Control (AIM Group®) Quality Representative is the selective inspection of the product/components/subassembly at different stages of the production line. This is carried out when the product is in current production. In-Process steel Quality Inspection is customer mandated and focuses on specific objectives:

Find the root causes of production defects detected during final steel inspection. In-Process steel Quality Inspection can be used by the customer with the objective of reducing on-going 100% inspection of all production lots. It can be used with other AIM Control Supplier Quality Control Services to bring the supplier into a state of Supplier Quality Self Control.

-

Verify the execution of Corrective Action Report (CAR) by the Supplier Production Team.

-

Inspect and detect poor quality linkages at different production stations.

-

Product and component quality inspection before assembly.

-

Identify supplier production weaknesses in the production system that leads to defects.

Steel Product Pre-delivery or steel Quality Control at Pre-Shipment Goods Inspection (PSI)

-

When was the last time you bought a shipment of scrap metal or garbage?

-

AIM Control (AIM Group®) inspection group provide customers with Quality Control at pre-shipment inspection services that will eliminate unexpected supplier product and quality surprises.

Pre-shipment inspection: is a way of making sure you get what you expect from the supplier. pre-shipment inspection means getting an inspector to do a check on what is being loaded into the container, what is in the boxes, and that it works. if you are a trading operation that buys a variety of consumer or simple products and consolidates your shipment, a quick 1-2 days pre-shipment inspection on your goods to verify the supplier’s obligations to you is probably what you need to prevent your losses

The PSI or FRI (Final Random Inspection) should take place when at least 80% of the production is reached and packed into export cartons.

Steel product Pre-loading Survey and Loading Supervision (LS)

This is the final step of quality control to loading cargo into containers, ship and transportation to seal for ensuring exactly the goods as contract.

-

Ship, Transportation, Container's condition visual inspection to certify it is suitable for loading of each kind of goods

-

Tallying of quantity loaded into each container

-

Sealing of container's doors after loading completed.

-

Photos of process.

Quality Control and Pre-shipment inspection, Loading Supervision services

In case of a failed inspection you should consider using our and ask for a Re-inspection. For some tricky shipments you might also consider a full carton/ products Inspection. We also help you to find solutions with your supplier.

YOUR REQUESTS:

How to make sure I will get what I paid for?

What type of defect is my production suffering from?

What is the % of defective products in my shipment?

Are my products functioning correctly?

Are my shipping marks, packing and labeling correct?

When? The Quality control/ Pre Shipment Inspection (PSI), also called Final Random Inspection (FRI) will take place when at least 80% of the products are ready and packed into export cartons. You can of course specify when booking online that you want 100% of the products to be ready for this inspection.

Where? The final random inspection or pre shipment inspection will take place at the factory; anywhere in Korea, India, China, Vietnam & International Local. In some case it could take place at the forwarder's premises or at the pier.

What? The Quality Control/ Pre-Shipment Inspection (PSI) and Loading supervision covers all possible on site checks of your products:

Ø Steel Product appearance inspection

Ø Steel Workmanship inspection.

Ø Steel Safety and function inspection.

Ø Steel Quantity inspection.

Ø Assortment inspection.

Ø Steel Unpacking checking, Colors inspection. (comparison to PMS Color with RAL Code)

Ø Steel Size measurements inspection, steel coil checking.

Ø Steel Weight inspection.

Ø Steel Zinc coating testing inspection.

Ø Steel thickness measurement inspection

Ø Labeling & logos inspection.

Ø Packaging & packing (including the shipping marks) inspection.

Ø Loading & Stuffing, Sealing supervision

+ Any other special requirements you may have...

Why? Because it is simply essential to check your products before the shipment! And this even if you work with a trading company or with an agent... Your vendor, whether he is a factory, a trading company or an agent will have no interest to inform you of any potential or real quality issue...

Trust is good... But control is much better !

Benefit & Advantages of this quality inspection:

Performing a Pre-Shipment Inspection will allow you to:

- Use our inspection report as a bargaining tool with your vendor!

- Know the percentage of defects affecting your products.

- Know the seriousness of the quality issues.

- Refuse defective shipments.

- Prevent to shortages of quantity & quality goods

- Bargain with your vendor in case of quality issue(s).

- Avoid unexpected costs & delays.

- Keep pressure on your vendor shoulders.

- Show your client(s) you care.

- Save time and secure your business!

AIM Group® is a leader in providing Quality Rolled & Plate Steel products pre-shipment inspections, Rolled & Plate Steel products carton loading supervision into reefer containers and ship.

-

Steel products factory audit (before purchase) in Vietnam, China, Asia and Global to request and adapt to Customers standard if necessary.

-

Steel products factory and supplier assessment (Hazard audit) in Vietnam, Asia and Global

-

Steel products Initial production check in Vietnam, Asia and Global

-

Steel products product testing in Vietnam, Asia and Global

-

Steel products during production check in Vietnam, Asia and Global

-

Steel products packages Labels & markings, logos check in Vietnam, Asia and Global

-

On site Steel products Health testing & Certificate in Vietnam, Asia and Global

-

Steel products production monitoring in Vietnam, Asia and Global

-

Steel products random inspections in Vietnam, Asia and Global

-

Steel products Sample Inspection in Vietnam, Asia and Global (Inspect samples in site at the suppliers' factory or have it delivered to AIM Control’s office)

-

Steel products weight measurements check in Vietnam, Asia and Global

-

Steel products packing and drop testing in Vietnam, Asia and Global

-

Steel products Pre-shipment inspection in Vietnam, Asia and Global

-

Steel products Container loading supervision in Vietnam, Asia and Global

-

Steel products Pre-loading survey / inspection in Vietnam, Asia and Global

-

Steel products Loading survey / inspection / supervision in Vietnam, Asia and Global

-

Quantity verifying and tallying in Vietnam, Asia and Global

-

Document inspection in Vietnam, Asia and Global

-

Rolled & Plate Steel products photos and report and certificate in Vietnam, Asia and Global

-

Rolled & Plate Steel products other consultant services in Vietnam, Asia and Global

-

AIM Control appointed dose not shield the supplier of basic responsible to deliver quality goods of Rolled & Plate Steel products and services in fulfillment of the sale contract (or P.O, PI)

Vietnam Albania Algeria American Samoa Angola Antigua Antilles Argentina Aruba Ascension Island Australia Austria Azores Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Bermuda Bolivia Brazil Brunei Darussalam Bulgaria Burkina Cambodia Cameroon Canada Canary Islands Cape Verde Islands Cayman Islands Chile China Colombia Cook Islands Costa Rica Croatia Cuba Cyprus Czech Republic Denmark Djibouti Dominican Republic Ecuador Egypt El Salvador Estonia Falkland Fiji Finland France French Guiana French Polynesia Gabon Gambia Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guam Guatemala Guyana Haiti Honduras Hong Kong Hungary Iceland India Indonesia Iran Ireland Isle of Man Israel Italy Ivory Coast Jamaica Japan Jordan Kazakhstan Kenya Korea Kuwait Latvia Lebanon Libya Lithuania Luxembourg Macao Madagascar Madeira Malaysia Maldives Malta Mauritius Mexico Micronesia Moldova Monaco Morocco Myanmar Namibia Netherlands Antilles New Zealand Nigeria Norway Oman Pakistan Panama Papua New Guinea Paraguay Peru Philippines Poland Portugal Puerto Rico Qatar Republic of Panama Romania Russia Samoa Saudi Arabia Scotland Senegal Sierra Leone Singapore Slovakia Slovenia Solomon Islands South Africa South Korea Spain Sri Lanka St. Kitts and Nevis St. Lucia St. Vincent Suriname Sweden Switzerland Syria Taiwan Thailand Trinidad and Tobago Tunisia Turkey Turkmenistan Turks. Ukraine United Arab Emirates United Kingdom Uruguay US Venezuela Virgin Islands Yemen Yugoslavia Zambia Zimbabwe at Harbor (Harbour), Sea Ports, any Vendors and premises of suppliers.

Other service :