Break Bulk Cargoes Holds Condition Survey

Break Bulk Cargoes Holds Condition Survey

A break bulk cargoes holds condition survey procedure and actions of AIM Control’s is aimed at helping ship-master, cargo officers, marine superintendents and chartering understand the requirement of ship’s cargo holds preparation before loading of break and bulk cargoes.

Under AIM Control’s surveyors consult in preventing any claims on cargo loss, contamination, costs, delay, and disputes over on-hire, off-hire and charter party issues

The break bulk cargoes holds condition survey is not just a question of sweeping, cleaning odors, there are a number of matters to consider and failing to adhere to good practice can result in substantial claims.

A lack of knowledge, often originating can be the underlying cause of major claims.

Cargo hold cleaning

-

Cargo contamination problems

-

Problems stemming from previous cargo

-

Cargo stain

-

Rust, rust scale and paint flaking

-

Unsanitary conditions

-

Wetness

-

Odours

-

Infestation

-

Safe

Various cargoes – hold cleaning requirements

-

Coke – general

-

Green delayed petcoke

-

Met coke

-

Bulk cement and clinker

-

Anthracite coal

-

Bituminous coal

-

Bauxite

-

Manganese ore

-

Salt

-

Soda ash

-

Sulphur

-

Fertiliser

-

Woodchips

-

After loading

-

Before arrival

-

Other cargoes

Hold structure

The conventional bulk carrier has a box construction with Tank top, internal shell plating, wing tank plating, coating, frames, bulkheads, top brackets, foot brackets, u/side cross deck, ladders, platforms, sounding pipes (dark sides), air pipes (dark sides), pipe protections, bilges and suctions, lighting, manhole covers, fire detectors, electrical cables, electrical connections, electrical switches, co2 pipelines, co2 discharge heads, ventilation, ventilation trunks/grills, booby hatches.

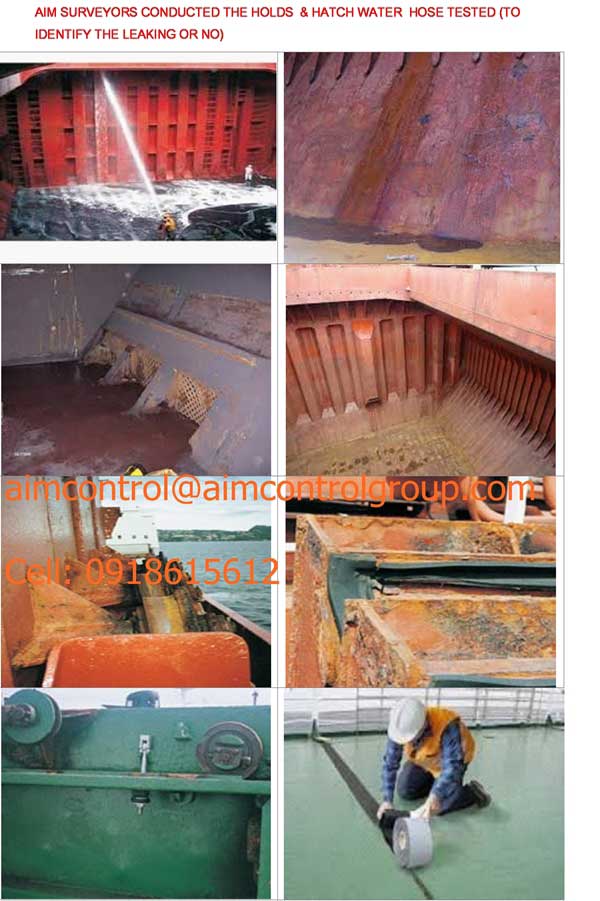

This is evidence of AIM Control’s one Ship's cargoes holds condition survey while Vessel anchorage at Cam Pha, Quang Ninh, Vietnam:

The break bulk cargoes holds condition survey (before loading)

-

Supervision and survey to find free from ANY previous cargo residues

-

Supervision and survey to find free from loose rust, scale or paint. Painted surfaces must be properly applied and cured

-

Supervision and survey to find dry and clean

-

Supervision and survey to find free from odours

-

Supervision and survey to find in all ways in a suitable condition, fit and safe to receive and preserve the intended cargo

-

Supervision and survey to find particular emphasis on previous cargo residue on overhead beams, hatch-end beams, hatch joints and hinges, frame brackets, pipe brackets, ladder ways, manhole covers etc

General

Although not part of a vessel cleanliness survey inspection it is requested that the following is also checked and reported on:

-

Supervision and survey to find all bilge covers, access covers, tank-top covers should be inspected and properly secured

-

Supervision and survey to find bilge wells should be clean and dry with pumps in good working order

-

Supervision and survey to find tank-tops should be free from protrusions, container fittings, pad eyes and the like

-

Supervision and survey to find hatch covers must be demonstrably watertight with all seals and sealing faces in position and properly maintained.