Quality Coconuts Control Inspection

Quality Coconuts Control Inspection (Before loading and during loading)

AIM Control (AIM Group®) quality coconuts control inspection carried out to certify that the shipment mentioned goods of coconuts are inspected during pre-loading inspections and also during loading. Email

The survey findings are indicated below

- Container no.

- Country of Origin

- Producer

- Description of the cargo

- Quantity (cargo pieces / net weight / gross weight) of the cargo declared:

- Packing of the cargo

- AIM Control’s check-list of the inspection of the frozen foods:

- Pre – Inspection

Actual quantity (cargo pieces / net weight / gross weight) of the shrimp’s goods loaded into the container

Organoleptic analysis

- Smell

- Color

- Taste

- Texture and

- Sizes

Marks and labels product verification

Temperature of the cargo (min and max value)

Stuffing Supervision

Container condition inspection

Packing condition

Storage supervision

Temperature control carried out inside chambers

Temperature control carried out inside chambers

Temperature control carried out during cargo stuffing

Container sealing

Quality inspection (additional quality requirements)

To control and inspect if all packing of the boxes are close well to verify quantity (pcs) of coconuts in each box

To control and inspect if each coconuts have straw

To control and inspect if all the coconut are fresh and don’t have any bad smell, or mold or stain of any problem can be and no any pests or worms

control and inspect that the coconut does not have mold and any pests

To control and inspect the goods under cold warehouse with right temperature which temperature surveyor found the goods during the inspection at the site.

To open 20 coconuts (at least) one of each carton to inspect and test the taste if is good and sweet and with out aftertastes or bitter

Control and inspect to the reefer container and make sure it is on the right temperature and leaves the factory with the right temperature must be 2-4 degree Celsius

To take pictures of loading container and temperature of the container

Additional notes

Collecting of shipping document and analysis other relation.

Report & Certificate

AIM Control (AIM Group®) Also conduct the Coconuts quality control inspection at some stage as followings

Raw Coconut product quality

Operation and hygiene

Processing & storage condition

Packing, Seal & Delivery

Distribution and temperature

Consumer & Consuming

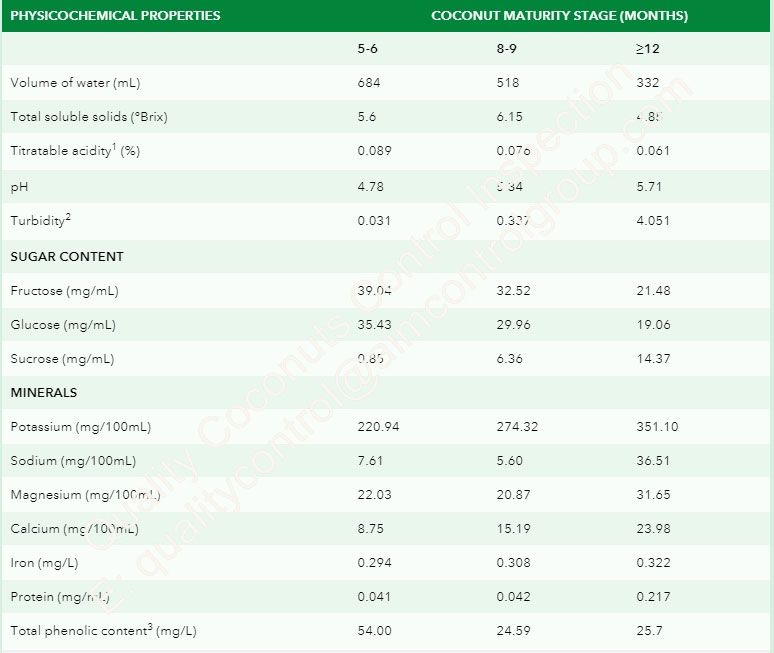

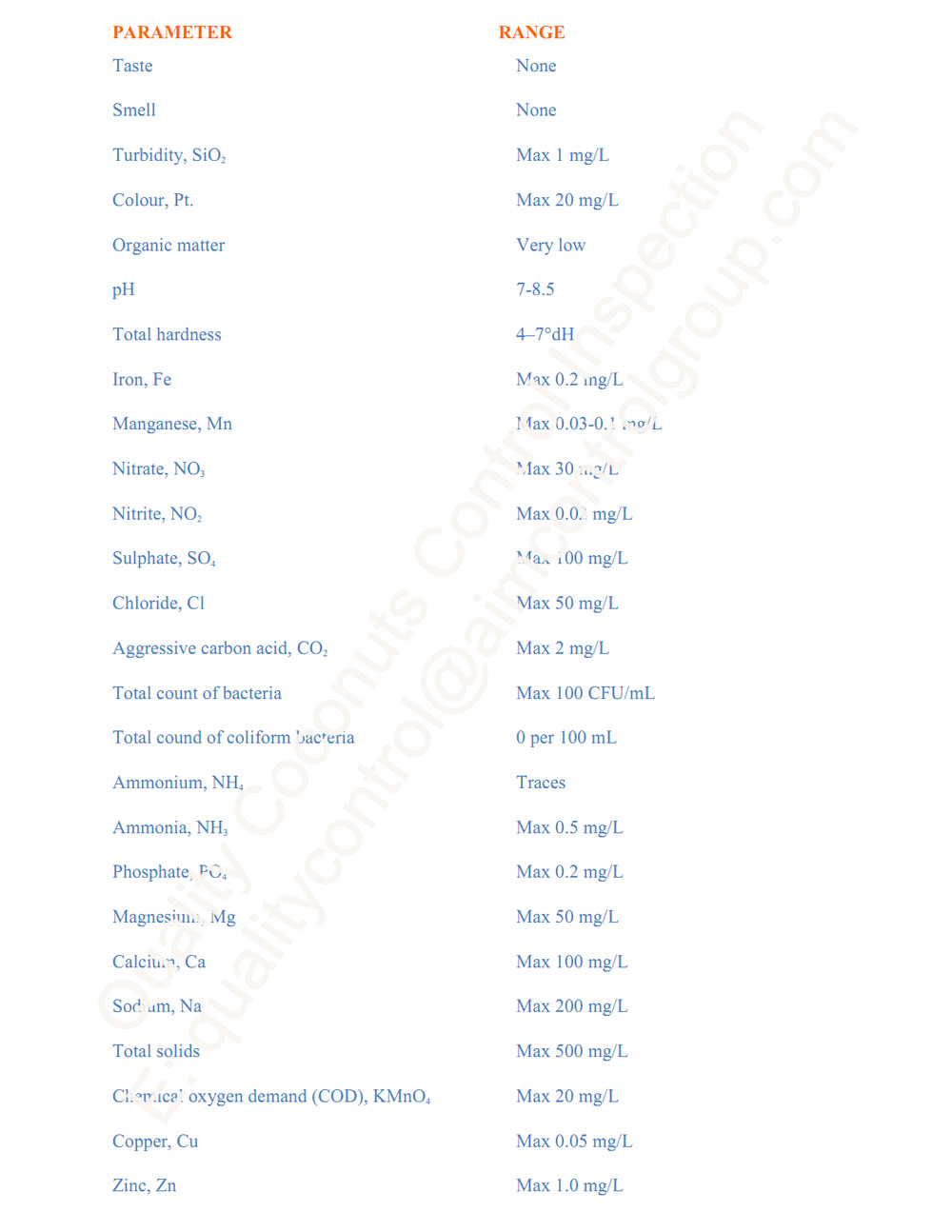

Young Coconut water and coconut milk based products quality standards

Flavour/odour

Total soluble solids °Brix

Dry matter determination

pH/ titratable acidity

Microbiological content

Sulphite test

Browning index determination

Optical density/ Turbidity test

Free fatty acids determination

Viscosity

Other activity :

- Quality inspector

- Face Mask Quality Control Inspection

- Fish fillet quality control inspection services

- Timber Wood quality inspection

- Crude and refined oil cargo test and inspection

- Boat Yacht quality inspection and discharging loading survey

- Consumer Goods quality assured inspection

- Zinc Oxide quality inspection and loading discharging supervision

- Freight Inspection of transport goods

- Product quality inspection