Walnuts quality control inspection services

Walnuts quality control inspection services

AIM Control (AIM Group®) specializes in providing food quality inspection services for nuts and seeds various kinds, including Walnuts quality control inspection services

What is specification of Walnuts

Walnuts are rounded, single-seeded stone fruits of the walnut tree commonly used for the meat after fully ripening between September and November, in which the removal of the husk at this stage reveals a browning wrinkly walnut shell, which is usually commercially found in two segments (three or four-segment shells can also form).

During the ripening process, the husk will become brittle and the shell hard.

The shell encloses the kernel or meat, which is usually made up of two halves separated by a partition within a fibrous sheath that splits when ripened.

The seed kernels – commonly available as shelled walnuts – are enclosed in a brown seed coat which contains antioxidants. The antioxidants protect the oil-rich seed from atmospheric oxygen, thereby preventing rancidity.

Walnuts with no shells are 4% water, 15% protein, 65% fat, and 14% carbohydrates, including 7% dietary fiber (table). In a 100-gram reference serving, walnuts provide 2,740 kilojoules (654 kcal) and rich content (20% or more of the Daily Value or DV) of several dietary minerals, particularly manganese at 163% DV, and B vitamins (table).

Types

The two most common major species of walnuts are grown for their seeds – the Persian or English walnut and the black walnut. The English walnut (J. regia) originated in Iran (Persia), and the black walnut (J. nigra) is native to eastern North America. The black walnut is of high flavor, but due to its hard shell and poor hulling characteristics it is not commercially cultivated in orchards.

Walnut Varieties

1) English walnuts

2) Black walnuts

3) Red walnuts

Storage

Walnuts, like other tree nuts, must be processed and stored properly. Poor storage makes walnuts susceptible to insect and fungal mold infestations; the latter produces Aflatoxin – a potent carcinogen. A mold-infested walnut batch should be entirely discarded.

The ideal temperature for the extended storage of walnuts is −3 to 0 °C (27 to 32 °F) with low humidity for industrial and home storage. However, such refrigeration technologies are unavailable in developing countries where walnuts are produced in large quantities; there, walnuts are best stored below 25 °C (77 °F) with low humidity. Temperatures above 30 °C (86 °F), and Humidities above 70 percent can lead to rapid and high spoilage losses. Above 75 percent humidity threshold, fungal molds that release dangerous Afflation can form.

Food use

Walnuts in their shells available for sale in a supermarket in the United States

Walnut meats are available in two forms: in their shells or de-shelled. The meats may be whole, halved, or in smaller portions due to processing. All walnuts can be eaten on their own (raw, toasted or pickled), or as part of a mix such as muesli, or as an ingredient of a dish: e.g. walnut soup, walnut pie, walnut coffee cake, banana cake, brownie, fudge. Walnuts are often candied or pickled. Pickled walnuts that are the whole fruit can be savory or sweet depending on the preserving solution. Walnut butters can be homemade or purchased in both raw and roasted forms.[citation needed]

Walnut oil is available commercially and is chiefly used as a food ingredient particularly in salad dressings.

Nutritional value

Unlike most nuts that are high in monounsaturated fatty acids, walnut oil is composed largely of polyunsaturated fatty acids (72% of total fats), particularly alpha-linolenic acid (14%) and linoleic acid (58%), although it does contain oleic acid as 13% of total fats.

Quality inspection of Organic walnuts

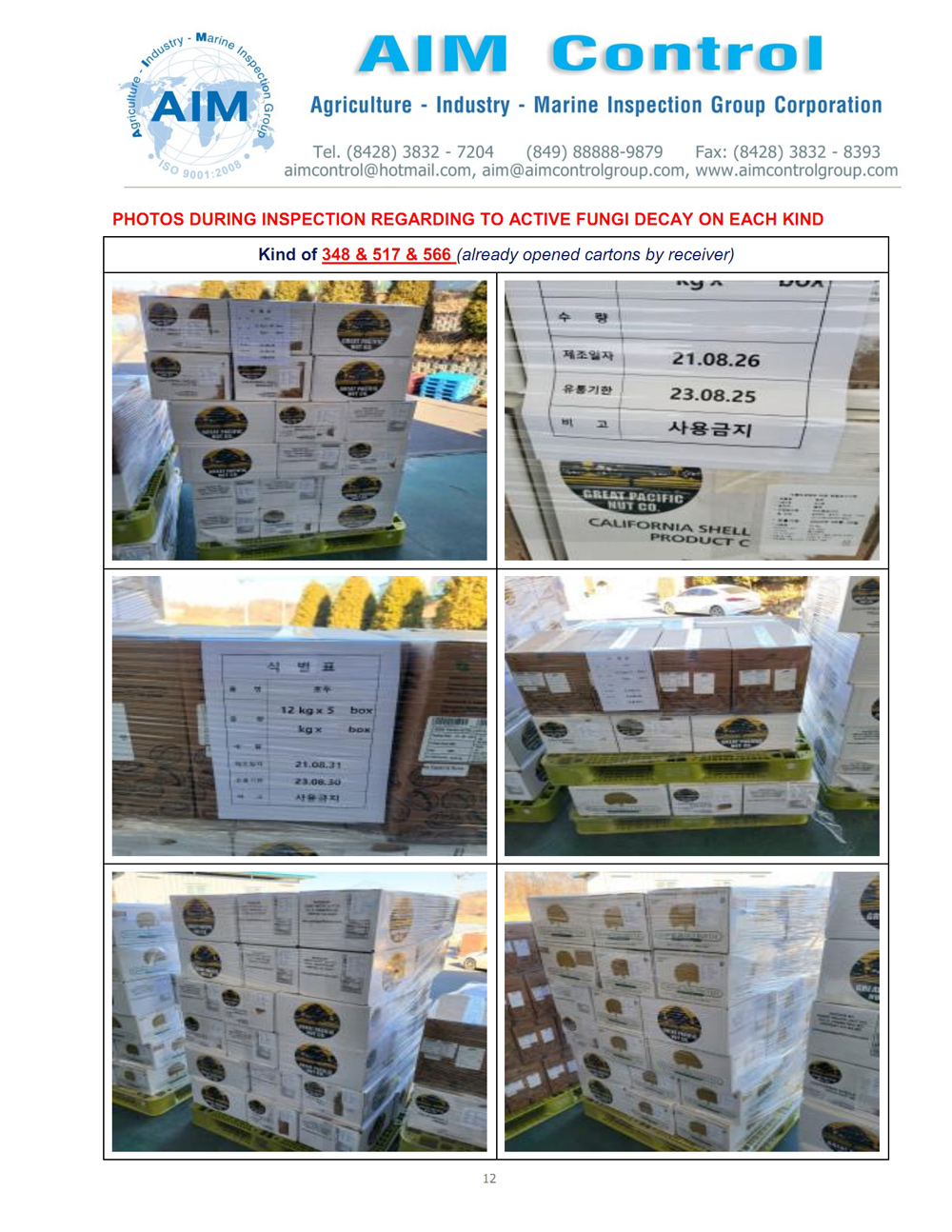

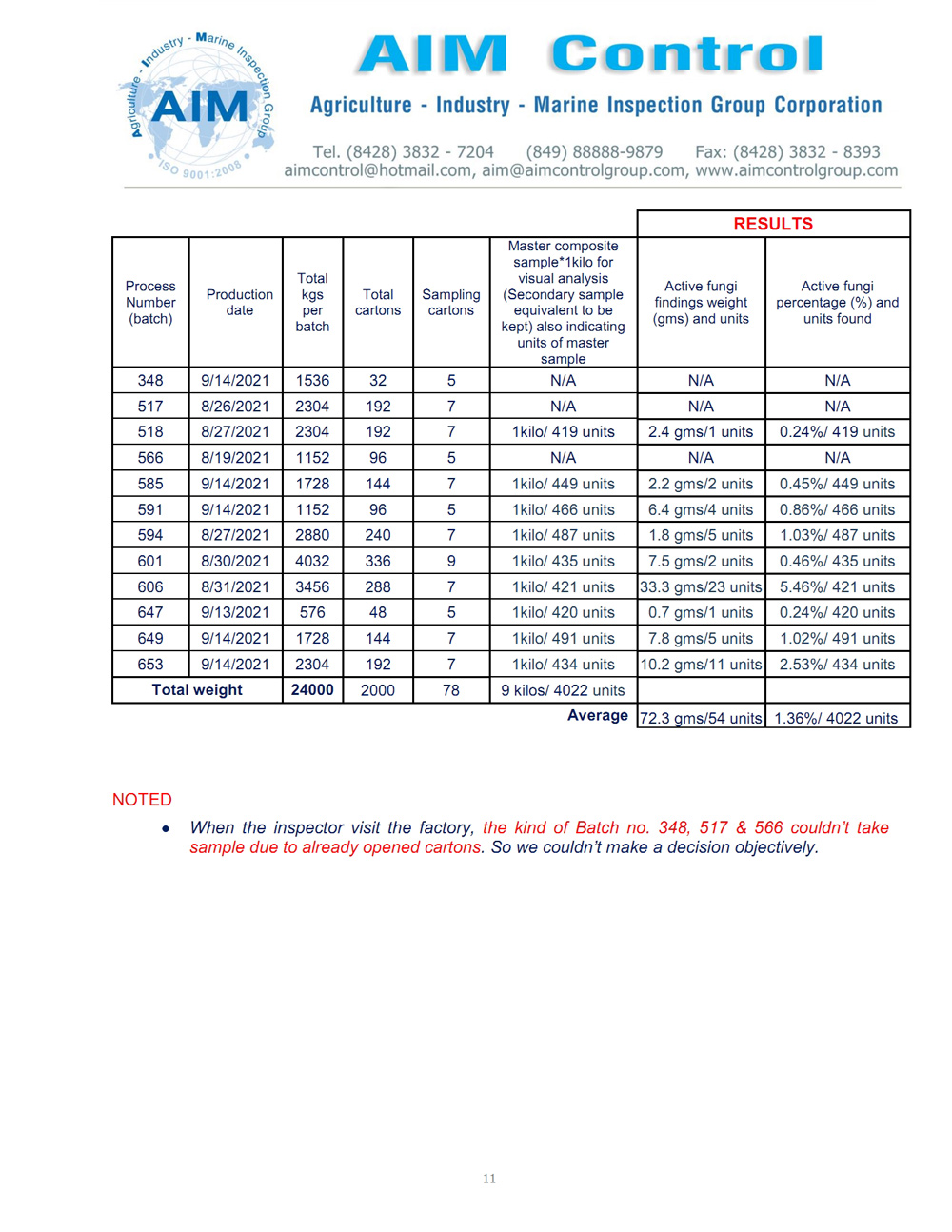

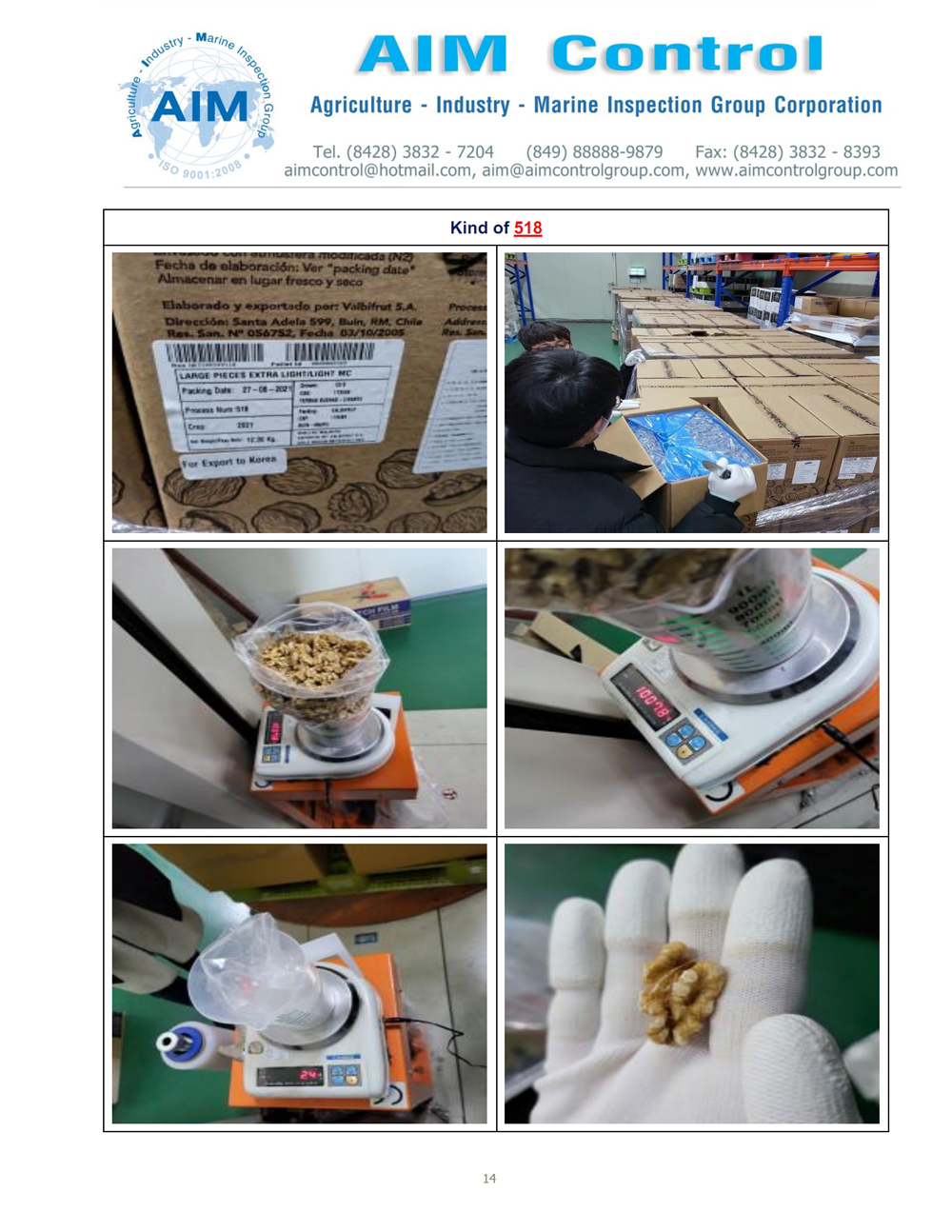

- Take number of carton samples of each kind (as the followings)

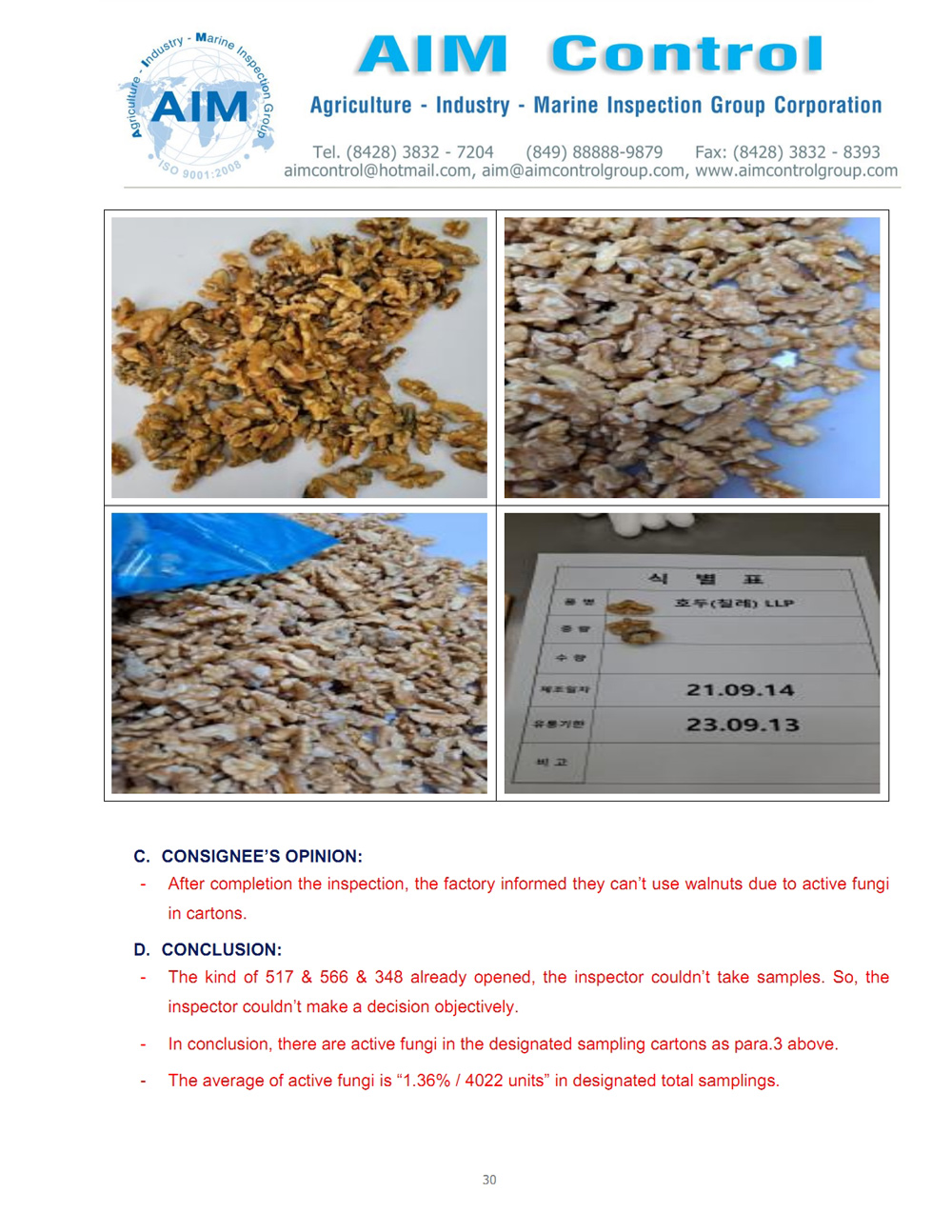

- Take one Composite sample (01 kg) from carton samples of each kind for visual analysis (Secondary samples)

- In the separated of Composite sample (01 kg) are checked visually to identity a Fungus decay

- Weighing of sample of each kind (01 kg) and weighing of Fungus decay to be identified in each sample (are weighed in carefully)

- Counting number of pieces of Fungus decay walnuts in each kind

- Counting number of pieces of walnuts in each sample of 01 kilo

- Take photos

- Videos in details (Some short video clips showing general process in progress clearly showing the presence of active fungi in walnuts)

- Report with calculate Rate of Fungus decay on each kind

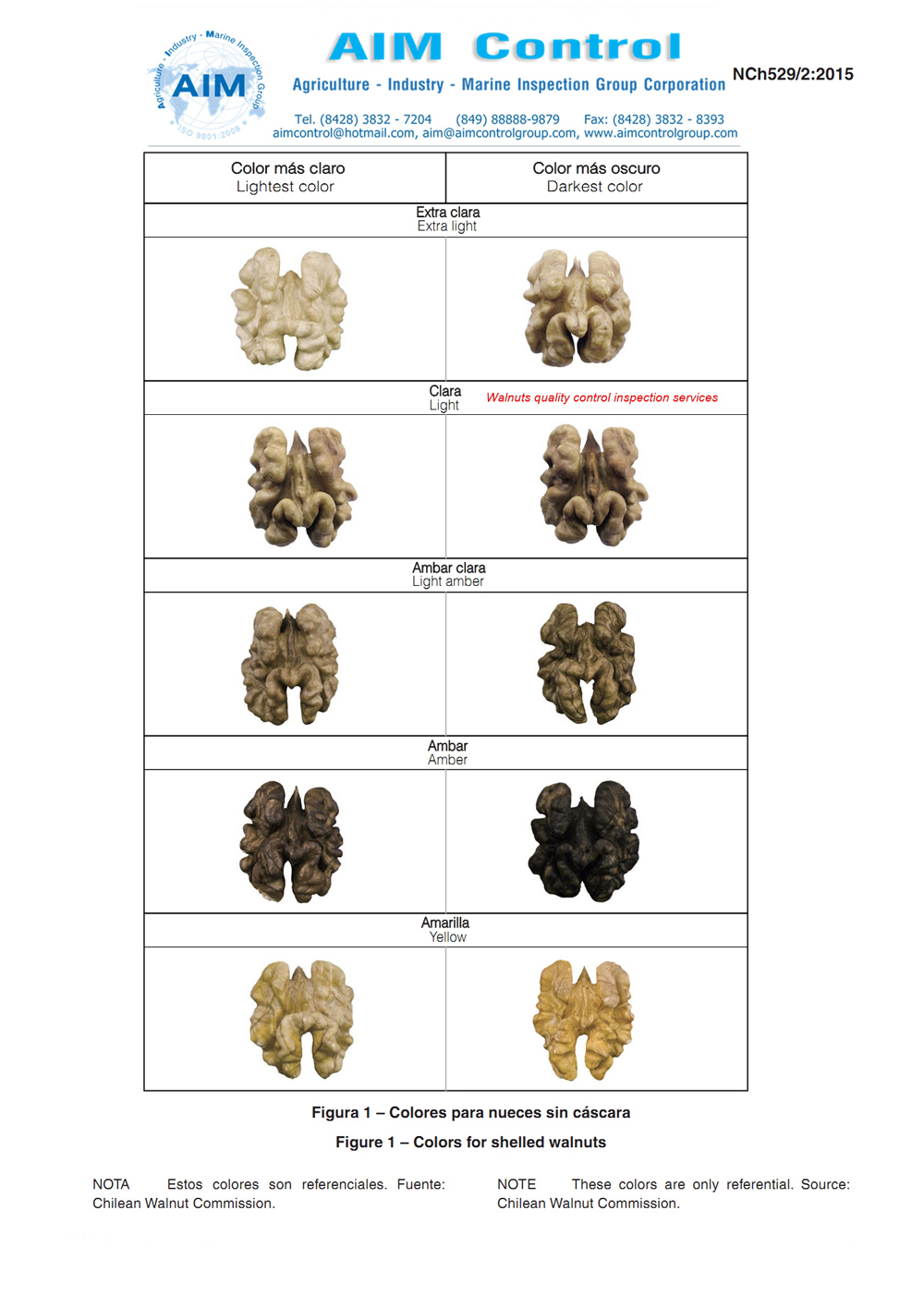

AIM Control (AIM Group®) quality inspectors will perform Walnuts quality control inspection services and sampling in strict accordance with the process and walnuts standards NSC MC - NCh00529-02-2015-046 - Chile and equivalent international standards.

Other news :

- Seller Supplier Factory Audit

- Inspection Services for Goods

- Sashimi grade tuna inspection

- Consumer product quality inspection

- Factory Assessment / Factory Audit Inspection

- Factory security Inspection safety assessment

- Food and Drink Quality inspection

- Testing and Inspection services for products

- Verification Auditing services

- Family Textile Products Test Inspection