Vessel Condition Inspection

Vessel Condition Inspection

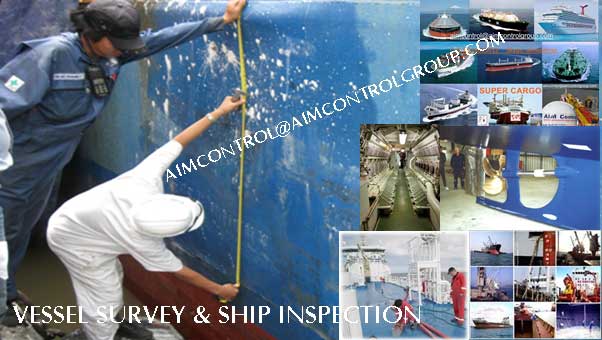

Vessel condition inspection is Full Condition of a Motor Vessel (ship) Survey on her technical condition. AIM Control’s full experience marine surveyors attending to the ship/vessel for verify all of following hull, machinery and equipment items of vessel/ship.

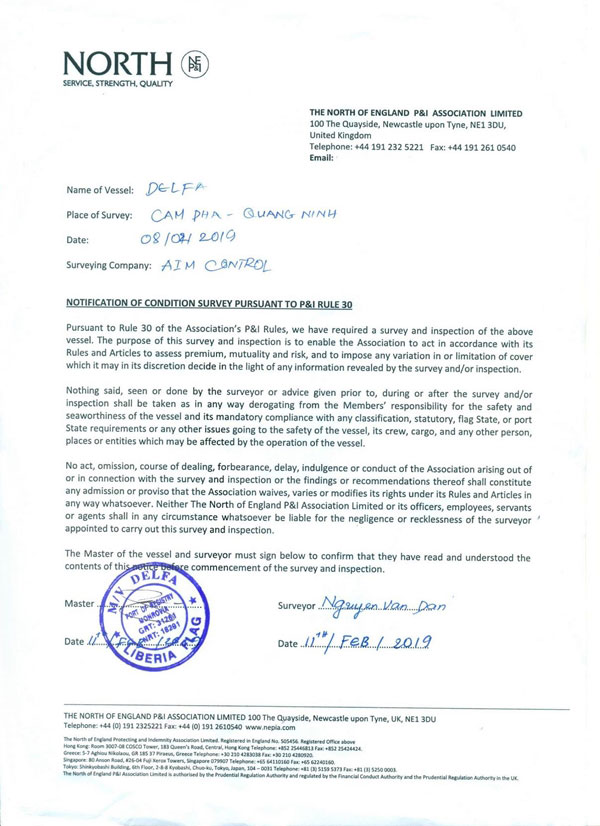

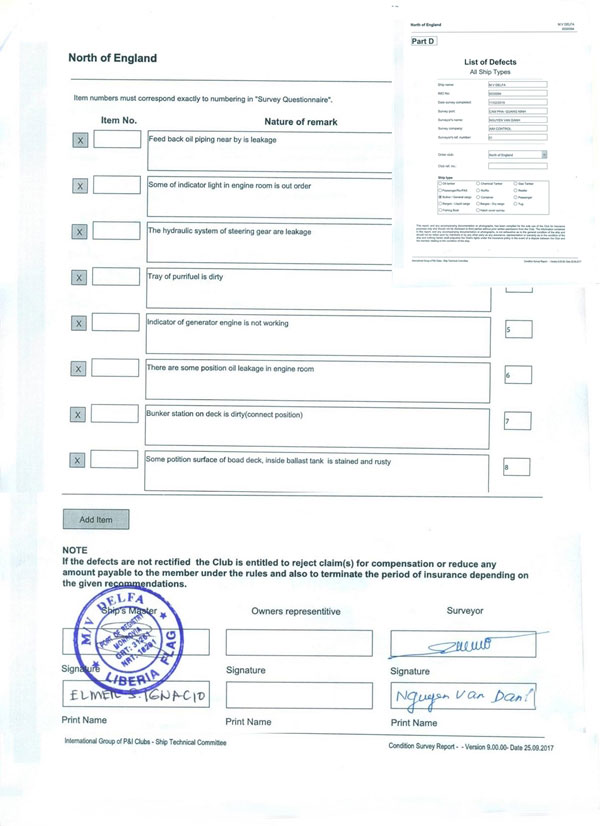

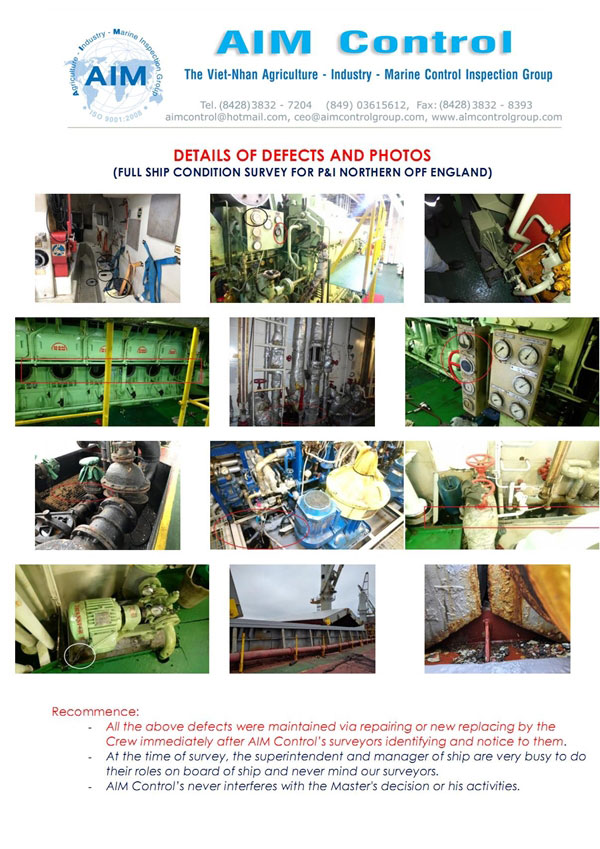

On behalf of a P & I Clubs (or other), AIM Control’s marine surveyors carrying out a pre-entry vessel condition inspection or a ship condition survey services to the vessel. and it was found ship's defects as the vessel’s cargo holds, hull shell plating had been in heavy corrosion. By an own-operated thickness test, the shell plating diminution was found to be beyond limit, so the vessel’s official thickness test report was suspected as fake. We fully reported the condition to the Club and the vessel was rejected. According to the survival crew, the vessel sustained an ingression in her cargo holds. (The bottom right corner was a photo taken by our surveyor to the cargo hold shell plating condition).

In a ship condition survey, the safety equipment, main engine and others as well structure also inspected to find the her defects for warning to Club, ship-owners, an technical department and superintendent to troubleshoot and maintenance for seaworthiness.

AIM Control also offers a diving inspection job to verify the underwater ship's hull, propeller, blade, sea-chest and parts of condition vessel when customer request adding.

AIM Control's Vessel Condition Inspection / Survey

As well as on board of ship visits the condition inspections / surveys of vessel to enable managers to determine whether entered ships conform to acceptable standards. These are completed on the AIM Control's Survey Form and are done on vessels for the following reasons:

-

When ships over 10 yrs old are entered in the club, this can be either a pre-entry or a post entry condition survey.

-

If after a visit by a club inspector, the inspector feels that the ship does not conform to the Clubs standards.

-

Following a claim which could possibly have occurred due to a lapse in on board maintenance/management.

-

If information is received from a third party e.g. PSC that the ship is below Club standard.

-

If the ship changes classification societies, usually from an IACS to a non IACS society.

-

If after a lengthy period of lay up (6 months or more) a ship is re-activated.

It is important to note the vessel condition survey are carried out by independent surveyors appointed by the ship inspection department. The attached Survey Guide (33 Rule) explains in more detail the processes involved with the survey system.

The motor vessel condition survey will include a visual inspection and usually we cover the following:

Section 1 Summary of survey and condition of vessel

Section 2 Publications and Statutory Certificates

Section 3 Management, Records and Manning

Section 4 Ship structure: External hull and superstructure, anchors, chains, windlass,

Ballast tanks, Deck equipment.

Section 5 Hatch covers, Derricks & Cranes and Holds, Cargo equipment

Section 6 Engine room, Machinery and Bunkering, Bilges, running hours if the main and auxiliary engines

Section 7 Bridge and Navigation

Section 8 Communications, antennas

Section 9 Life Saving Apparatus /Fire Fighting Equipment

Section 10 General items, crew accommodation spaces

Section 11 ISM Items, ISPS Code items, Ship and machinery log books

Section 12 Defect list and Condition Statement

Section 13 Annexes: Ship's plans, Deflection reports, Spares reports,

last cargo voyages, etc.

Section 14 Pictures

Some accidents also could happen to the new buildings, we have done several cases concerning this kind of claims in recent years.

The main areas of concern were:

Service and maintenance: pilotage and bridge navigational procedures, position fixing records under pilotage, engine room and store crane maintenance, engine room procedures, ventilators, winches, mooring ropes, deck plating fittings, and charts, nautical publications and P&I information. Safety: emergency escape facilities, lighting, machinery guards, sounding pipe sealing and oily bilges in the engine room; safe working procedures for crew; and fire hoses and fire fighting equipment maintenance.

Cargo worthiness: hatches and hatch covers - maintenance, cleats, sealing tape, packing and watertight integrity.

Pollution: engine room leaks, bilges and sounding pipe sealing, garbage disposal procedures, hydraulic leaks on deck and on steering gear, bunker tank air vents and MARPOL infringements.

Manning: ARPA/radar training, language barriers, masters on watch, insufficient navigation officers and non-compliance with STCW 95.

Operational performance: poor general standards and PSC matters.

AIM Control says the comments are "sometimes critical but are very largely constructive. Our ship inspectors have built up such a vast well of experience that they pass on examples of good practice to others. Generally, this is much appreciated by masters."

To gain entry to the Club, all ships over 10 years are subject to independent condition surveys - prior to entry whenever practicable although most are conducted afterwards within a specified period. Entered ships may also undergo surveys, for example where deficiencies are revealed during the handling of claims; where serious defects are noted by the inspectors; at reactivation following lay-up; and following changes of classification society.

The following is AIM Control's evidence of Full vessel condition survey / inspection conducted by AIM Control's Marine Surveyors in Hai Phong port, Vietnam:

Some tests for system and equipment

-

Water hose of hatch covers (or ultra)

-

Bilge suction in cargo holds

-

Emergency steering gear

-

Emergency fire pump

-

Emergency generator

-

Navigation lights including “burned lamp alarm”

-

Oily water separator alarm

-

Fire dampers on engine room air vents

-

Shut off valves for FO / DO service tanks

-

A few smoke or fire detectors in the accommodation

-

Reefer room alarms

-

Remote ventilation stop in the galley

-

Internal ballast water inside

-

David

-

Bridge machinery and equipment system

-

Engine room machinery and equipment system

REASON FOR INSPECTION: Rule 33.

Detailed instruction from the club below: Club Reference No.

AIM Control Surveyors familiarise AIM Control’s selves with the renewal version of these instructions.

Vessel Type

Policy Details

The following highlights the relevant policy details so please bear these in mind whilst conducting AIM Control Full Ship condition inspection.

Area of Navigation and Operational Details: Asian Far East waters only.

Policy Clauses:

Loss of or damage to property (Fixed and Floating Objects FFO) - Rule 2 Section 8

Liabilities in respect of seamen - Rule 2 Section 1

Pollution - Rule 2 Section 9

Wreck liabilities - Rule 2 Section 12

Cargo Liabilities - Rule 2 Section 14

Collision with other vessels - Rule 2 Section 7: Including full collision liabilities (4/4ths)

Other Details

The above vessel is a Container Carrier.

The survey report is a private and confidential document and copies should not be given to any third parties.

The 18 typical motor vessel condition inspection and survey jobs (marine ship):

-

Sale and purchase condition inspections (PPI.)

-

P&I Entry (Full condition survey).

-

Ship Condition Survey (Annual Appraisals, Rule 20B, Rule 20B(3)).

-

Ship Condition Valuation Survey (Appraisal inspection).

-

Appraisal of the design condition during and after construction.

-

Vessel seaworthiness survey (Ship's condition survey for loading at port and navigating at sea).

-

Voyage approval inspection and certification (First ship's navigation condition inspection).

-

Full on-hire survey, Full off-hire survey (delivery and redelivery).

-

Maintenance survey.

-

New Shipbuilding Inspection/inspectors and Witness, Supervision (for Hull and Partition fabricated inspection, M/E, Machineries and devices Fit-Up inspection, supervision and witness for new construction)

-

Dry docking New Ship building condition survey as per ITP.

-

Ship's repair condition manual inspection and Dry-docking ship condition inspection.

-

In water Propellers, Blade, Sea-chest Clean survey,Underwater Hull Condition inspection. (in lieu of Dry-docking/ UWILD).

-

Classification Register inspection (Periodical surveys as stipulated by the rules to ensure continued maintenance of conditions).

-

Other Vessel's condition surveys.

Purpose of a full motor vessel condition inspection / survey

Purpose of AIM Control’s a ship full condition survey is to identify the ship/vessel is not only suitable for entry her P&I Club or re-entry but also on the structure and equipment of ship for purchase or others.

As part of AIM Control’s Vessel Full Condition Survey is also recommend the Membership continued efforts to maintain and improve their ships’ standards, condition and technical defects.

The root role of AIM Control’s Vessel full condition inspection is to identify her deficiencies with a list of items in need of rectification. The Full condition survey report will send to the her Club.

The vessel condition surveying is to a vessel’s condition was pursuant the agreed terms and conditions of the insurance policy.

The vessel full condition inspection survey is also to her to ensure compliance with safety, fitness, seaworthiness and the standards, continue to meet the rules.

Others, the ship's condition inspection is as pre-purchase vessel condition survey

ALSO REFERENCE AIM UNDERWRITER'S SURVEYORS

AIM Control can do the vessel condition survey for all of various ship kinds

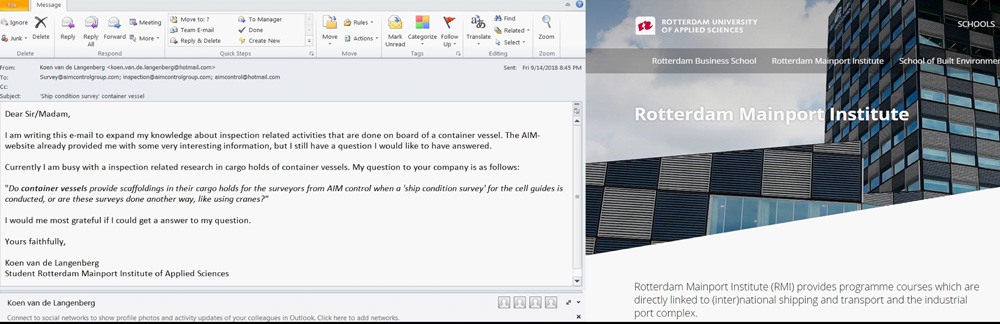

Aslo see the professor of the Rotterdam Mainport Institute (RMI) emailed to be got AIM Control Inspection Group's advices