Heavy lift crane inspection

Heavy lift crane inspection and devices equipment certificate

AIM Control offers the heavy lift crane inspection and devices equipment certificate for all of lifting of cargo in standards.

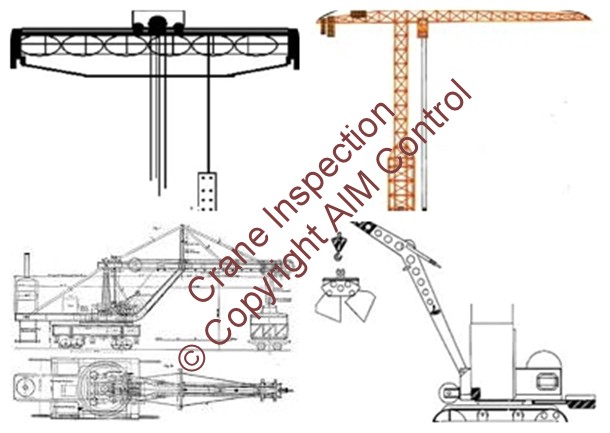

There are two types of cranes MOBILE & FIXED

Mobile

Truck-mounted, rough terrain, crawler, floating, other types as

All terrain, Pick and carry, Side-lifter, Carry deck, Telescopic handler, Harbor, Railroad, Aerial.

Fixed

Tower, Components, Assembly, Operation, Self-erecting tower cranes, Telescopic, Hammerhead, Level luffing, Overhead, Gantry, Deck, Jib, Bulk-handling, Loader, Stacker.

Lifting and hoisting equipment are in some countries subject to local statutory regulations. New constructed equipment is to be assessed and approved by accredited bodies; in-service inspections are often in place to ascertain integrity of these potentially dangerous equipment. AIM Control Industrial Services is accredited for Lifting and Hoisting Equipment in a series of countries, for Conformity Assessments as well as for Statutory and Voluntary Inspections. They are the only Lifting and Hoisting Equipment that needs NoBo type approval under this directive. Constructors, importers and users of lifting and hoisting equipment take advantage of our many years' experience, the modern equipment and expertise of AIM Control. Email: inspection@aimcontrolgroup.com

Industrial Services provides Statutory Inspections on Lifting and Hoisting Equipment as part of the client’s risk assessment program and to meet the legal requirements for periodic inspections. The object of this service is to independently assure safe and proper working capabilities and conditions of cranes and other lifting and hoisting equipment by inspecting the equipment in accordance with all-applicable regulations, standards and good engineering practice. Once a crane has been found to be in safe and proper working condition, documents of certification can be issued in accordance with the local laws or those of the destination of the lifting device.

In some regions, AIM Control can use it’s multiple accreditations to provide combined statutory inspections, offering approval for more than one country with one inspection.

Statutory Inspections on Lifting and Hoisting Equipment applies after complete or almost complete assembly / installation of the device and then at regular intervals thereafter.

There are four scopes of heavy lift crane inspection and certification

- For new crane (safety and statutory requirements)

- For maintenance (repairing and renewal)

- For accident (damage / loss)

- For condition (before operation of lifting)

The field of application includes

Material-handling devices (cranes, derricks, forklifts, shackles, hooks, etc)

Personnel handling devices (elevators, escalators, ski lifts, cable cars, MEWP’s etc)

Inspection, maintenance and testing program will help ensure a crane is safe to use and should be done in accordance with the manufacturer’s instructions on specifications or according to relevant technical standards and engineering principles.

The typical inspections for heavy lift crane can be included

- Complete inspection of the mechanical, structural, electrical, and safety systems as well as of the wire ropes and chains. Inspection includes, but is not limited to, the requirements of all governmental regulating agencies.

- Non-destructive testing of the load hooks for cracks and visual inspection for distortions; inspection of all the structural loadbearing members, including the sheaves. For overhead cranes, checking of the crane girders, rails and columns to assure structural integrity.

- If required, performance of dynamic / static load tests. While under load, re-checking for possible defects such as distortions, cracks, loose bolts. Checking of brakes, clutches, sheaves, and wire rope assemblies.

- After load test, conduct operational tests in order to reassure that the unit is functioning properly.

- Re-examine of all safety devices.

- Setting up of a complete equipment file on each unit containing a daily, weekly and monthly check sheet, and results of the initial inspection.

- Repair supervision

- Remnant life assessment

- Line level and span crane gantry surveys

Where required, all devices which are inspected and certified are affixed with a label indicating the expiration date, inspection / certifying agency, and other relevant information. After completion of the inspection, a report will be prepared to list the deficiencies to be corrected.