Freight forwarding goods inspection

Freight forwarding goods inspection

AIM Control (AIM Group®) offers freight forwarding goods inspection is to ensure safety in transportation and avoids risks such as damage, loss and shortage of cargo.

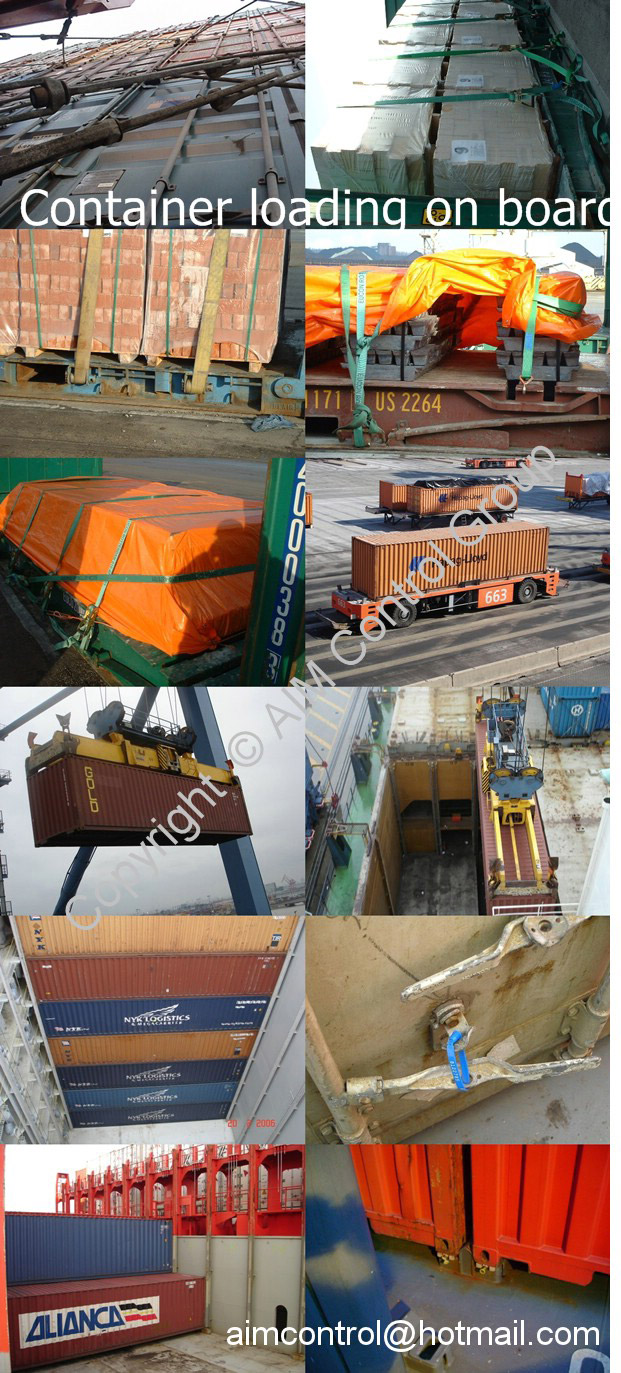

AIM Control (AIM Group®) shipping goods inspections consisted of Container loading survey and Ship loading survey.

1. Freight forwarding goods inspection for ship

Shipping loading survey is called loading of goods inspecting and supervising on board of ship's cargo holds, deck and port's berthing to prevent loss and damage before transportation at sea.

Shipping discharging survey is called discharging of cargo inspecting and supervising on board of motor vessel's cargo holds and port's yard to prevent loss and damage as well controlling and calculation weight, quantity and quality of shipment receipt.

How to freight forwarding goods safety and prevent loss and damage?.

Shipment surveyed when at exporting via loading from harbors ports of countries of suppliers/ sellers on carrier's ship until discharging at destination port and receiver's warehouse.

Port of loading to destination.

The shipment will be loaded into holds of ship at port of loading (the exported countries) when her berthing, anchorage or buoying to prevent shortage of weight / quantity and to reject damage / defects may be caused during pre-loading, loading.

Survey of Hatch covers and cargo holds condition

Before loading, the hatch covers of ship are surveyed to ensure that it is watertight, her holds are surveyed to ensure the cleanness and free-smell for suitable loading of cargo into ship’s holds (without affect to new cargo will be loaded)

Verification of cubic numbers:

Some types of goods are large packages or liquefied gases, liquid cargoes in transit need to measure and calculate volumes by cubic numbers.

Sampling of shipment during loading and discharging is an important process in the transportation business wherein AIM Control's independent surveyor (marine cargo surveyors) will be acquiring several bags, cartons in random order, random solution of figuring out called the sampling of products (as sample standard other requirement) and to survey, moisture test, weigh, etc.

Quantity of shipment survey is tallying of numbers on bags, cartons, packages. . .AIM Control (AIM Group®) will makes sure that the quantity of the shipment is correct to avoid problems as the shortage of lot of cargo.

Weight survey of shipment:

Weight of shipment survey before loading or discharging is monitored and strictly supervised by AIM Control (AIM Group®) cargo inspector to avoidance of possible damages and other problems that manufactured shipment may cause via draft survey, weighing 100% of shipment (or random).

Also, AIM Control (AIM Group®) cargo surveyor should not forget the neatness, presentation and the safety of every shipment on those bags, cartons, packages and this procedure its positioning on the bags and the packaging itself as well writing and printing of marking, material made bags aiming meet to the standard of selling in market, transportation.

Lashing and securing (or re-lashing):

In case, the cargo is big packages as steel, wood log, container . . .then all of these packages must be lashed and securing to cargo hold's structure (or frame of container) to prevent a moving during voyage.

Sealing & Quantity tallying survey:

The quantity tallying survey is also carried via counting of bag by bag, carton by carton, package by package while each sling of cargo lifting from port passed to on deck or from cargo holds to shore.

After loading of shipment completed, AIM Control (AIM Group®) marine surveyor will seal all of hatch covers and man-holds as well as entry into cargo holds to prevent loss and theft (or checking seals condition before discharging).

Shipment stowage & dunnage supervision:

Shipment stowage & dunnage supervision carried out in parallel loading operation for suitable seaworthiness.

Inspection certificate and report of freight forwarding goods survey:

At loading port, before the signature Master Receipt & Bill of lading, or payment of value of purchase order remaining, we will issue the report of shipment loading inspection consisting of results of survey and photos.

At discharging port, before the signature Cargo Receipt Report & Outturn Cargo Report, we will issue the report of shipment discharging survey consisting of results of survey and photos.

2. Freight forwarding goods inspection for container:

Container loading survey is called inspection on loading of shipment into container with supervising, tallying and sealing to certificate of results.

Sampling of shipment:

Sampling of cargo container is an important process in the import business wherein an examiner (surveyor, inspector or auditor) will be acquiring several boxes in random order, random solution of figuring out called the sampling of products (as AQL, other requirement) and to survey, test, measurement, etc.

Weight survey of shipment:

During loading or discharge, weighing of bag by bag, carton by carton, package by package and incremental plus.

After that weight of container, goods & truck to minus tare truck and empty container at initial weighed

Quality survey of shipment:

Quality survey of shipment is to control all of specification of shipment are suitable with PO (order)

Packing and Marking survey:

Tallying and Sealing:

Certificate and Report of results of survey:

The followings are evidence of AIM Control (AIM Group®) shipping loading survey of shipment into container.