Supercargo loading survey lashing securing inspection

Supercargo loading survey lashing securing inspection services

In Shipping of supercargo, the safety is first! its operation therefore to have AIM Control (AIM Group®) supercargo loading survey lashing securing inspection services

Heavy lifting of supercargo loading survey and lashing securing control services are to check condition of cargo, checking the condition of packing and packaging, quantity tally, size of random checking (or 100% for packages), monitoring to the loading operation into transportation (vessel, ship, container), monitoring to lashing, securing of cargo, packages together each and into monitoring to and related activities aimed at preventing to damage and / or loss caused to the goods before loading time and during loading period to prevent all of risks and peril.

We also carried out to visual check/survey the quality of cargo, quantity of cargo, and measurement of cargo sizes (for oversize) before loading or pre-shipment on board of vessel or ship. Lashing and Securing inspection is intended to determine the packages of cargo were lashed and secured in satisfactory condition to suitable for shipping transport at sea.

It is in these circumstances that please contact with us at: aimcontrol@hotmail.com, cell: +84903615612 to be provided loading survey or securing and lashing supervision services by our local surveyor can be most useful for you to prevent the damage and/loss of cargo or verification cause of damage, loss and shortage for the loaded cargo/goods/products.

Loading supervision & lashing inspection for super cargo, heavy-lifting of project cargo carried out by AIM Control (AIM Group®) current world trend for green energy and for project cargo specialists who have the required capabilities in the supply chain management and supervision, inspection, witness, verify and certification of oversize plant and equipment, e.g. wind turbines, generators, turbines, reactors, boilers, towers, casting, heaters, presses, locomotives, boats, satellites, military personnel and equipment at manufactory, onto land transportation, loading port, loading on board of vessel, discharging. . .

What is supercargo? Project cargo is a term used to broadly describe the national or international transportation of large, heavy, high value or a critical (to the project they are intended for) pieces of equipment.

Project cargo is also a term used in the international industry to describe Supercargo.

What is heavy lift? The transportation, handling and installation of heavy items which are indivisible, and of weights generally accepted to be in the range of 1 ton to over 1000 tons and of widths/heights of more than 100 meters that are too large to fit into normal or onto conventional transporters.

These oversized items are transported from one place to another (sometimes across country borders) then lifted or installed into place. Characteristic for heavy lift goods is the absence of standardization which requires an individual transport planning.

To transport heavy lift items special trucks or trailers (flatbeds), Break Cargo Vessel are used, which are especially suitable due to their large loading area and capacity. For air transport special large-volume cargo aircraft like are employed which can move up to 250 tons of freight. On inland waters barges are often used.

Transports at sea carry out special heavy lift vessels which often possess won cranes for loading and discharging cargo.

Transportation of heavy lift items ranks among the most challenging and complex services in logistics and is handled by specialized companies, at sea for example by the project and heavy lift carrier.

Super cargo Loading survey & Lashing inspections and heavy lift supervision activities of AIMControlGroup.Com on the Transportation means:

- For shipping line/ sea transportation as Ship, Vessel, Containers, Lash, Etc.,

- For Land transportation: Trucks, Forklift, Wagon, trailers . . .

- For Airlines, aircraft.

Typical items of supercargo to be inspected and supervised by AIMControlGroup.Com

- Supercargo/ heavy lift cargo: Cranes, Tandem Crane, Vessel, Airline, etc.

- Project cargo: Towers, Structure of manufactory, oversize plant and equipment, e.g. wind turbines, generators, turbines, reactors, boilers, towers, casting, heaters, presses, locomotives, boats, satellites, military personnel and equipment

- Other

Example: AIM Control (AIM Group®) lashing surveyors / inspectors carried out jobs of supercargo loading survey / lashing inspection for project cargo at the M.V BBC Congo, MV Jan Van Gent, M.V Beluga Fusion, M.V SCL Bern, M.V Scan Pacific, vessel feet of Beluga Shipping GmbH., BBC Shipping, since 1993. Project Name’s 720 MW UTE - COAL FIRED POWER PLANT - Ceará, Brazil, at Doosan Heavy Industry Corp. loading and Dung Quat Port, Vietnam to Brazil, Project Name’s: IPC cape Scott, at Vung Tau Port, Vietnam to Canada port: Project Name’s: Algeria Omania Fertilizer Project at Penglai, China ports to Algeria port. Project Name’s: Brigadier Lopez at Vungtau, Vietnam Port to Argentina Ports. . .

Activities of supercargo loading survey lashing securing inspection of AIMControlGroup.com for Supercargo and Heavy Lift

- Measurement of volume for supercargo/ Heavy lift packages

- Supervising & witness upon land transportation of Loading & Lashing inspections from Factories to ports or opposite

- Checking and collecting document of shipment

- Checking the capacity of vessel’s cranes, bell sling, chain. . .

- Checking dunnage and lashing material

- Checking vessel and transportation are suitable for transport and seaworthiness

- Meeting to Port Capt., Vessel’s Master, C/O to find the stowage plan is suitable for loading.

- Meeting to Port Capt., Vessel’s Master, C/O and concerning parties to the synchronous of entire activities of loading and/ or discharging

- Loading inspection and supervision

- Witness and writing the packages No. and position of stowage plan

- Tally of packages quantity

- Witness and supervision of lashing and securing

- Consultant of Port Capt., Vessel’s Master, C/O for stowage packages of supercargo/ heavy lift in order during loading

- Consultant of Port Capt., Vessel’s Master, C/O for lashing of packages of supercargo/ heavy lift in order

- Writing and report the defect or incident to Supercargo / Heavy lift cargo during loading

- Issuance of Incident/ Accident Report of Supercargo / Heavy lift to request Master and Concerning parties signature and stamp.

- Phone and contact with requirement personal for updating news and status of loading, discharging. . .

- Super Cargo Services

Our services motto:

Cargo Safety – Cost Saving – Swift Distribution

Our head & branches offices of surveyors and experts for loading of super-cargo:

- Hochiminh city, Vietnam

- Vung Tau City

- Hai Phong City

- Da Nang City

- Binh Son, Dung Quat, Quang Ngai, Viet Nam

- China

- Korea

- India

- Chille

- Italy

- U.K

- Germany

- Japan

- Others

The followings also are AIMControlGroup.Com other services from us

Loading inspection, loading supervision provided by AIM Control (AIM Group®) Inspection Group at all of ports worldwide to supercargo loading, lasing, discharging to avoid problems such as wrong goods shipped; wrong quantity shipped, damaged merchandise or damaged packaging.

- What is exactly loaded on board my ship’s holds?

- How to inspect/survey/supervise sure of the exact quantity of goods inspection?

- How to inspect/survey/supervise sure the factory will not replace goods/cargo/product?

- How to inspect/survey/supervise sure vessel/ship crane, holds is safe for the loading?

- How to inspect/survey/supervise sure vessel/ship is safe for the transport?

What to inspect/survey/supervise on loading?

- The loading inspection covers quality verification, the quantity checking, the packing list checking, survey to condition ship’s holds, supervision to the process of the loading (cartons/packages conditions) and also a quick inspection on selected sampling size to check the workmanship, main functions, capacity of ship’s crane, capacity of forklift, checking to packaging and packing, checking to tags name, markings, checking to condition of loaded sling, checking to lashing belt capacity, checking to tags name, measurement of sizes.

- Check packaging (inside and out) for physical damage

- Check all quantities of merchandise

- Perform a random Quality “spot-check” on the merchandise

- Supervise the loading process

- Record the seal number and departure time of ship’s holds

- Weather, truck forklift, forklift, sling, lashing material etc…

- Supervise lashing, securing, dunnage

- Record the incident and accident to goods, packages if having any damage

- Record the time sheet of loading

- Consultant the lashing/loading condition as Port Capt., Loading Mater

- Collect the document of B/L, Certificates. . .

When to inspect/survey/supervise on loading?

With the Vessel/Ship (SLS), supercargo loading survey is also called Ship Loading Supervision, will take place right before the PORT and STEVEDORE is supposed to load the goods into the holds of ship/vessel and also during the loading process.

Where to inspect/survey/supervise on loading?

- At the ports or anchorage or buoying (for ship, vessel)

- Manufactory's vendors

How AIM Control can support your organization with RISKS Control and management for super-cargo and heavy lifting

The videos taken at the site of inspection, survey and supervision during AIM Control (AIM Group®)surveyors and inspectors conducted the loading survey and securing inspection for Super Project Cargo in over-weight and over-sizes

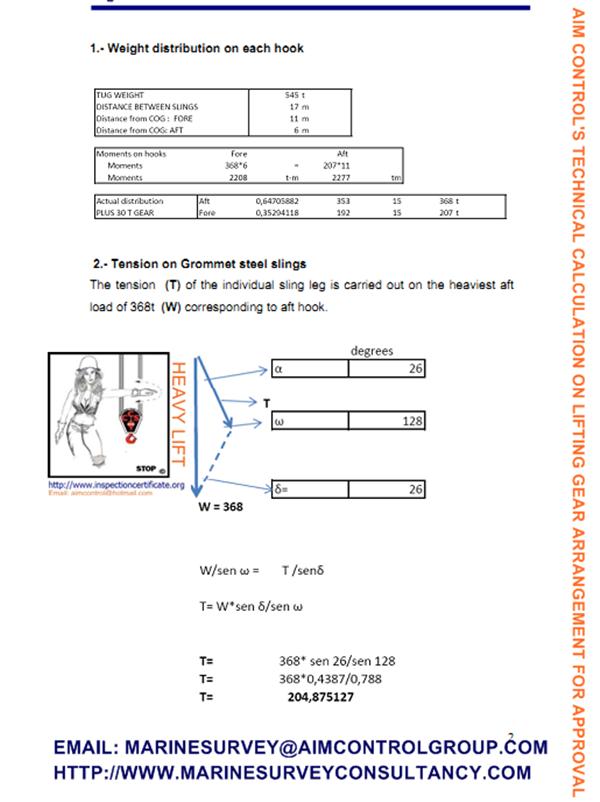

EXAMPLE OF AIM CONTROL'S CALCULATION

AIM Control (AIM Group®) heavy lift technical calculations in safe for one tug boat load on board of vessel under AIM Control (AIM Group®) Supercargo Experts supervised of in Busan Port of Korea:

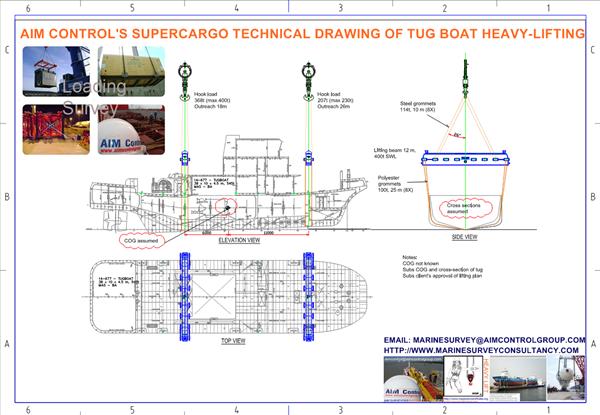

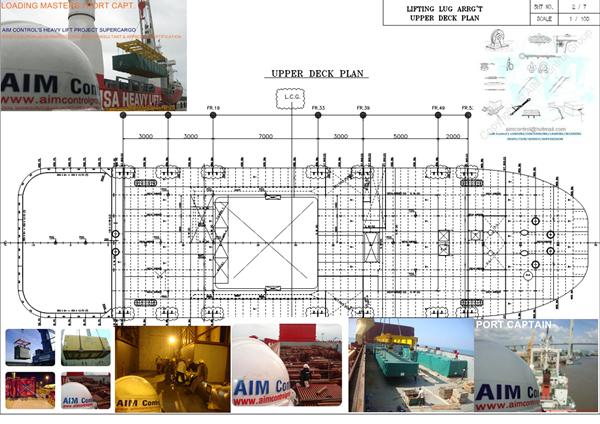

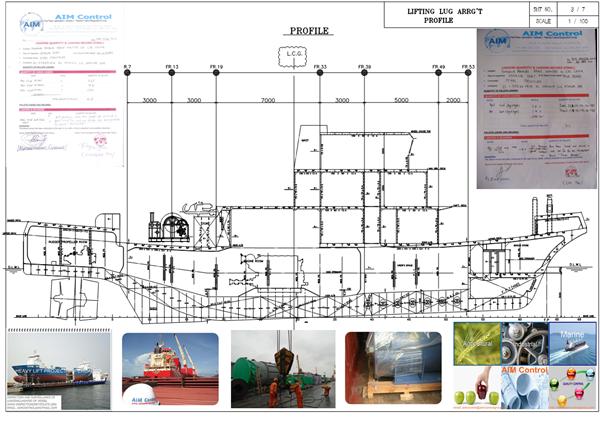

AIM Control (AIM Group®)heavy lifting experts have been requested to carry out calculations on lifting gear arrangement in order to load a 545 tug boat by means of ship’s cranes consisted in two (2) deck cranes of 400t capacity each.

AIM Control (AIM Group®) Heavy Lift Technical Calculations were based on the drawings prepared by AIM Control (AIM Group®) Technical Department (attached herewith) and further details discussed over the phone with Dr Capt. Nguyen Te Nhan and/or Master Mariner Nguyen Thuan Nghia / Nguyen Sy Huy and technical Port Captains from AIM Control (AIM Group®) Vietnam Head office.

We are in a position to report as follows:

Summary and Conclusions

Accordingly, the load in aft hook equivalent to 368 t will be distributed in two sling legs with a load of 205 tons tension each. Each leg connecting the hook with the respective spreader end will be supported by 2 grommets steel slings 10m length and 114 tons safe capacity each.

The load at the heaviest end equivalent to 368 t will be supported by 4 polyester grommet slings 25m long and 100t safe capacity each attached to an spreader of 400 t SWL.

The total load equivalent to 575 tons will be supported by 8 polyester grommet slings 25m long and 100 t safe capacity each.

Having considered that the tugboat cross section profiles are not available at present it was discussed and agreed with the Capt. of AIM Control (AIM Group®) at the site of loading that at all times the slings and spreader will be maintained clear from the tug accommodation block.

From information made available it appears that the rigging lay out described on the attached drawings should be considered adequate and safe provided all equipment including ship’s gear is duly certified by recognized organizations and is found in good conditions of maintenance.

This Report is based on facts presently known to the attending surveyors and is issued without prejudice to the rights of whom may concern. The right to amend or supplement this Report should additional information be made available is reserved.

Encls: · Drawings