The cargo flexi tank inspection and survey report

The Cargo Flexi Tank Inspection And Survey Report in Marine Voyage and Risk Management I www.AIMControlGroup.Com

We always understand that goods are transported by Flexi containers and that preventing contamination is extremely important. Our certification and inspection offerings aim to manage risk, which are important components of ocean shipping as they help ensure the safety, efficiency and profitability of high-value cargo operations. and used as food for humans.

However, managing risks associated with cargo and Flexitanks can be a complex and challenging task, requiring specialist knowledge and expertise. This is where consulting services come into play. All risks controlling involves the provision of expert advice, guidance, and support to shipping companies, cargo owners, and other operations. Consultancy services can cover a wide range of areas, including:

• Loading planning and supervision

• Risk assessment & control

• Compliance with regulations and standards testing / analysis

• Safety and security for cargo survey

• Environmental audit

• Business and Shipping

Why are The Cargo Flexi Tank Inspection and Survey Report?

-

Expertise and Knowledge: Consultancy firms specialize in providing expert advice and inspection services on the complex issues involved in Flexi Tank and Foods. This expertise and knowledge can help our customer companies make informed decisions, minimize risks, and optimize their operations.

-

Cost-Effective: It allows the customer to access specialized expertise and knowledge in expensive technology and equipment.

-

Compliance: our firms can help all customers ensure compliance with regulations and standards, which can help prevent fines, penalties, and legal disputes.

-

Risk Management: AIM Group can help to identify and manage risks associated with all operations, such as Thief, Commercial fraud, environmental hazards, or cargo damage claims. This can help prevent accidents and losses, and protect the reputation and profitability of the company.

With Our inspection and surveyors services involve expert advice and support for managing risks associated with trading and shipping for Good & Flexi Tanks covering a range of areas, including container selection, cargo planning, cargo quality and quantity, transportation handling, pumping management, environmental compliance, and insurance claim surveying...

Conclusion:

Contact us I www.AIMControlGroup.Com

https://aimcontrolgroup.com/en/inspection-service.html

email: aim@aimcontrolgroup.com

Refer to AIM Group's image report during the process of carrying out 02 inspections for goods and Flexi Tanks:

1. Photographic Damaged Survey Report for Cargo Flexi Tank Inspection inspectors:

2. Photographic Inspection Report - Flexi Tank Cargo at Pumping:

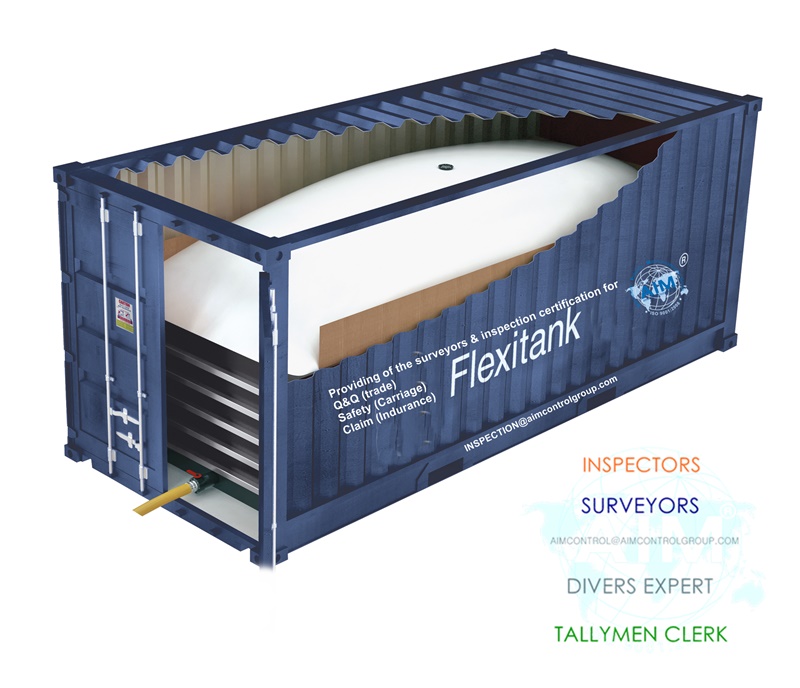

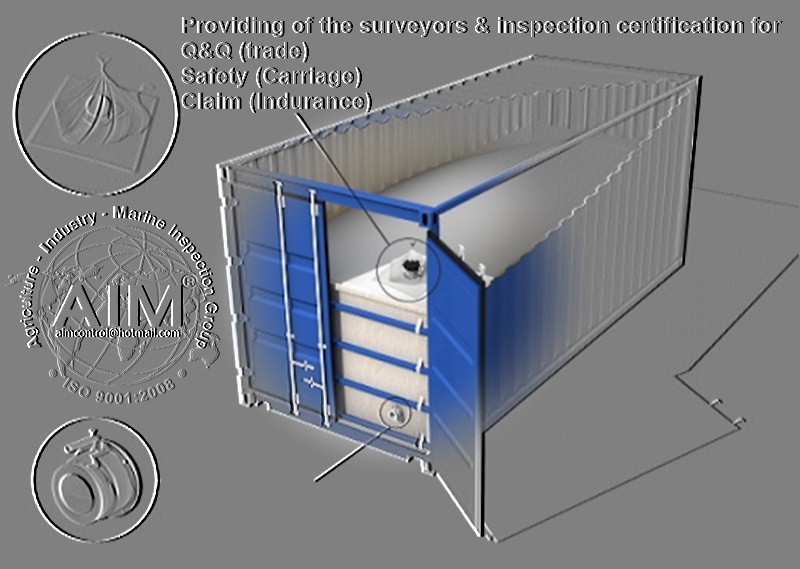

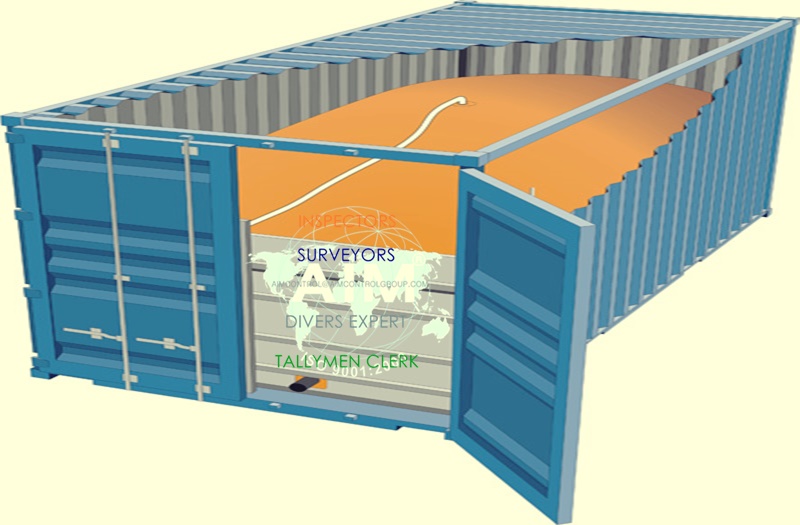

What is a flexitank container?

A flexitank is a type of bulk liquid bladder pouch or bag that allows shippers to fill dry containers with a massive amount of liquids. Holding up to 24,000 liters a bag (equates to 6,500 Gallons), flexitanks are constructed using multiple layers of flexible yet durable plastic film to store liquid contents safely.

What is the difference between Flexitank and ISO tank?

Flexitanks can only carry non-dangerous or non-hazardous liquid substances whereas an ISO tank can handle both dangerous (DG) and non-dangerous liquids. Compared to shipping packaged goods, the large volume carried by bulk shipments make the cargo naturally resistant to temperature changes during transit

What are the different types of flexitanks?

Flexitank models are available in 16,000L, 18,000L, 20,000L, 22,000L, and 24,000L. Some companies also offer a range of 1,000L up to 100,000L — depending on the customer's requirements

What material is a flexi bag made of?

Flexi bags are made of high-tensile-strength polyester fabric that has been coated on both sides with elastomer or plastomer (PU, PVC, nitrile). The flexi bags were invented during World War II in order to transport diesel

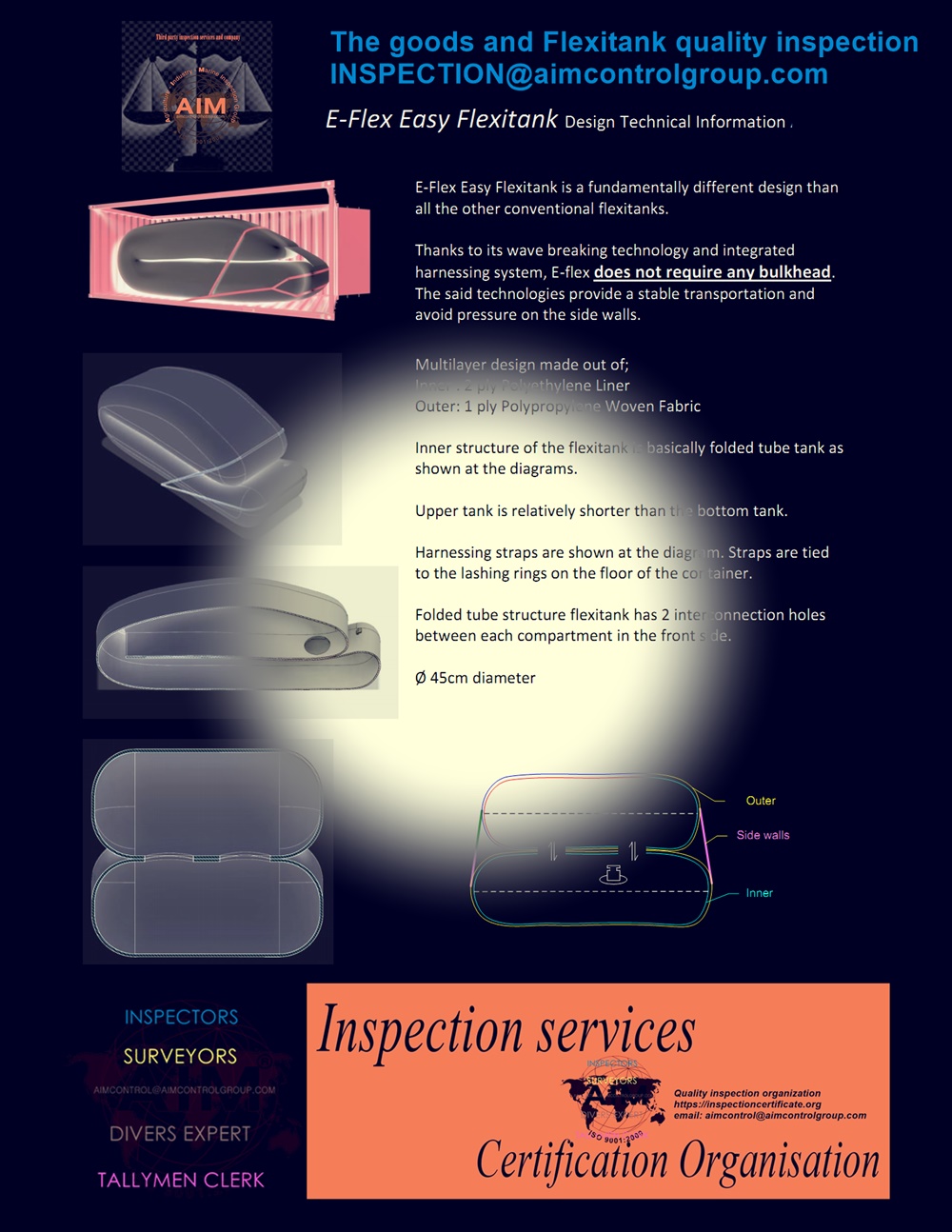

The below is one E-Flex Easy Flexitank:

E-Flex Easy Flexitank is a fundamentally different design than

all the other conventional flexitanks.

Thanks to its wave breaking technology and integrated harnessing system, E-flex does not require any bulkhead. The said technologies provide a stable transportation and avoid pressure on the side walls.

Multilayer design made out of;

Inner: 2 ply Polyethylene Liner

Outer: 1 ply Polypropylene Woven Fabric

Inner structure of the flexitank is basically folded tube tank as shown at the diagrams.

Upper tank is relatively shorter than the bottom tank.

Harnessing straps are shown at the diagram. Straps are tied to the lashing rings on the floor of the container.

Folded tube structure flexitank has 2 interconnection holes between each compartment in the front side.

Minutes of damage inspection for flexitank ships and transported goods (arising from accident risks and complaints

The damaged survey report for flexitanks and cargo in shipping (arrising of accident and claim)